Antimicrobial food packaging

A food packaging, anti-microbial technology, used in packaging, wrapping paper, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

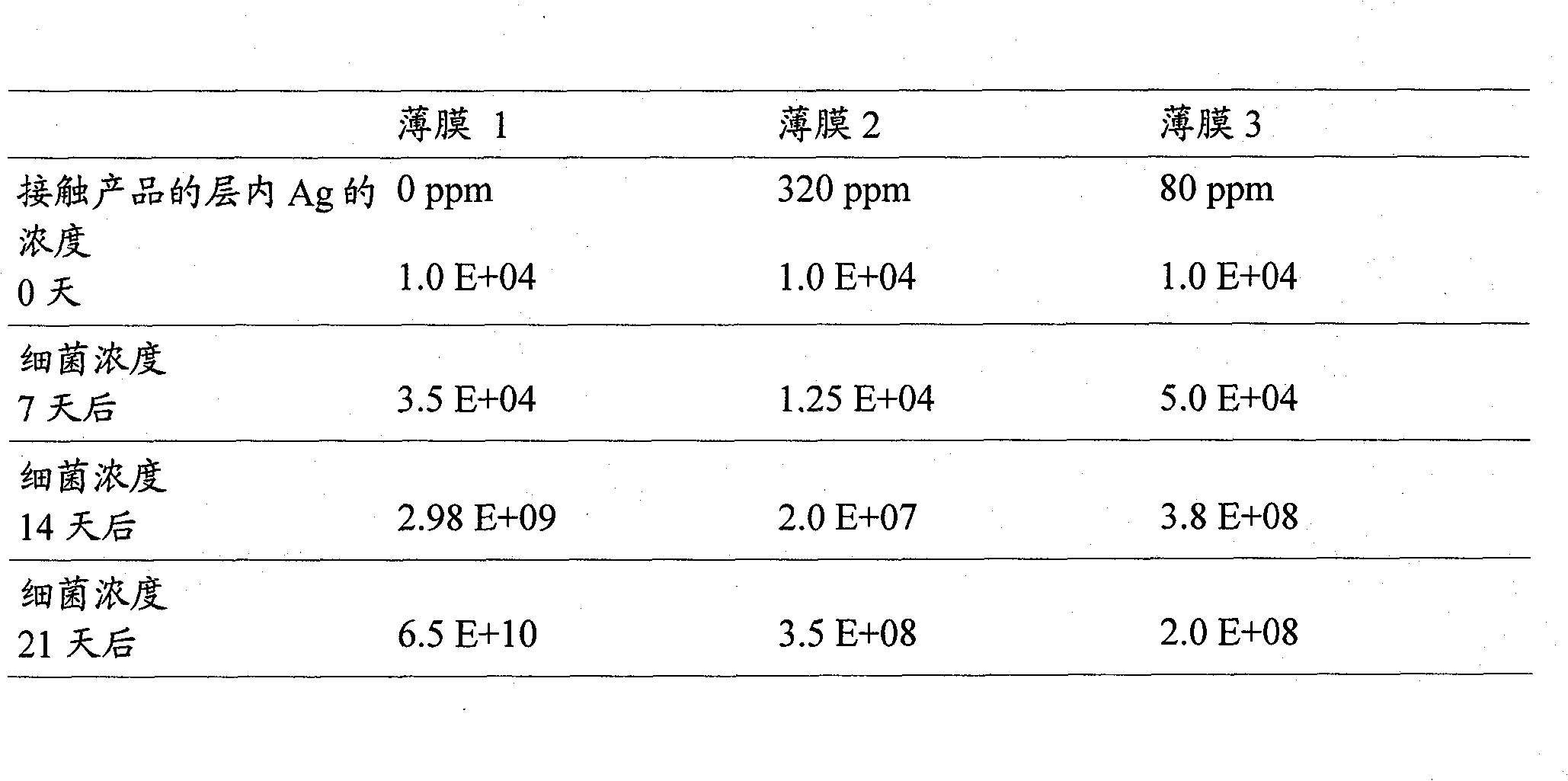

example 1

[0033] First, 100 ml of diethylene glycol (DEG) was heated at reflux and allowed to cool to room temperature. 1g AgNO 3 dissolve in it. The solution was then heated in a water bath. Above 50°C, the initial yellowish solution turned to light gray, which is considered to be indicative of the formation of agglomerated silver particles. The solution is concentrated and mixed into a polymer particle material, which is injected into a twin-screw extruder, and then processed into the middle layer of a multi-layer tubular film by co-extrusion.

example 2

[0035] First, 100 ml of triethylene glycol (TEG) was heated at reflux for one hour. After cooling to 150°C, under vigorous stirring, slowly and concomitantly add 5 ml of 0.1 molar AgNO 3 solution and a 0.2 molar solution of polyvinylpyrrolidone (PVP with a molar mass of 20,000). The suspension formed during extrusion of the tube in such a way that the concentration of Ag is 50 ppm relative to the mass of the polymer of the inner layer in contact with the product is added as an additive. This addition is carried out at a temperature in the range 180-220°C.

example 3

[0037] In 100 ml of triethylene glycol (TEG), 10 g of PVP was dissolved at 150°C. The PVP typically has a molar mass in the range of 6,000-20,000. Subsequently, 1-5 g of AgNO was dissolved in another 100 ml of TEG with stirring and heating and in the presence of the surfactant sodium lauryl sulfate (1-5 g) 3 . The surfactant sufficiently stabilizes some of the silver nuclei formed and inhibits their further growth. The rest of the silver particles grow into coarse particles, which are also stabilized by encapsulation after adding the PVP-TEG / PVP solution after 0.5-24 hours, preferably 1-5 hours.

[0038] The resulting bimodal particle size distribution shows transient effects due to the fraction of smaller particles. In contrast, the coarser fraction resulted in a longer period of bacterial inhibition due to a kind of reservoir effect.

[0039] The suspension thus formed is added to the polymer during extrusion of the tube in such a way that the Ag concentration amounts to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com