Water-cooled permanent magnet synchronous motor with a built-in outer rotor and rotary transformation magnetic resistance for hybrid power automobiles

A hybrid electric vehicle, permanent magnet synchronous technology, applied in synchronous machine parts, electrical components, electromechanical devices, etc., can solve the problems of high power density and small motor size, achieve long life, improve anti-interference ability, and reliable use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

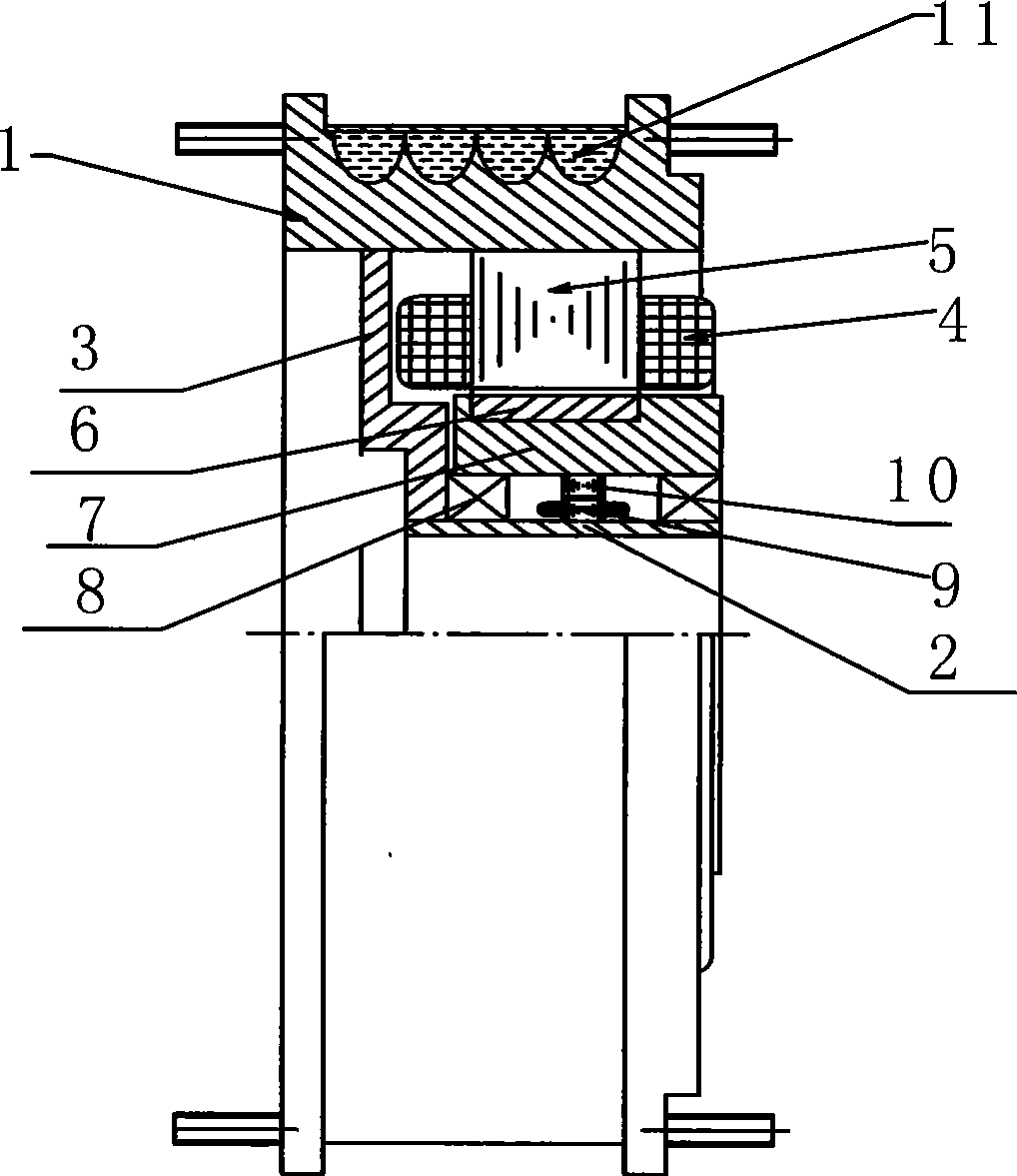

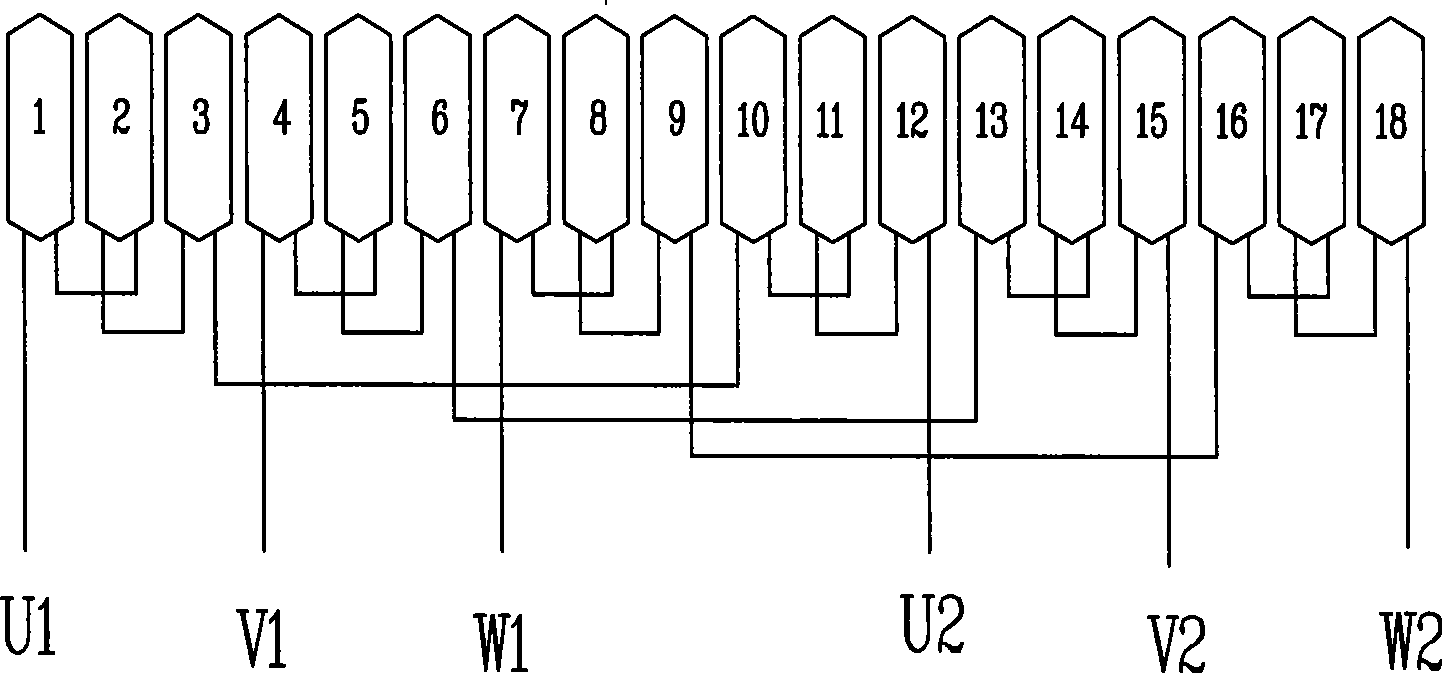

[0013] Such as figure 1 The shown built-in outer rotor reluctance resolver hybrid electric vehicle of the present invention is a water-cooled permanent magnet synchronous motor, which includes a casing 1, and a dummy shaft 2 with a hole in it is arranged in the middle of the casing 1 , one shaft end of the false shaft 2 is fixedly covered with an end plate 3, and the two ends of the end plate 3 are respectively fixed on the inner wall of the casing 1, and installed on the inner wall of the casing There is a stator core 5 with stator coils 4 wound thereon, and a rotor bracket 7 on which a rotor magnetic steel 6 is installed is installed on the outer wall of the dummy shaft 2 through a bearing 8. The stator core 5 and the The above-mentioned rotor magnetic steel 6 is arranged oppositely, the rotor 10 of a rotary transformer is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com