Porous aluminum oxide film light filter with bifurcate holes and preparation method thereof

A technology of porous alumina and thin-film optical filters, applied in the direction of optical filters, anodic oxidation, etc., can solve problems such as difficulty in improving efficiency, lack of filtering effect, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

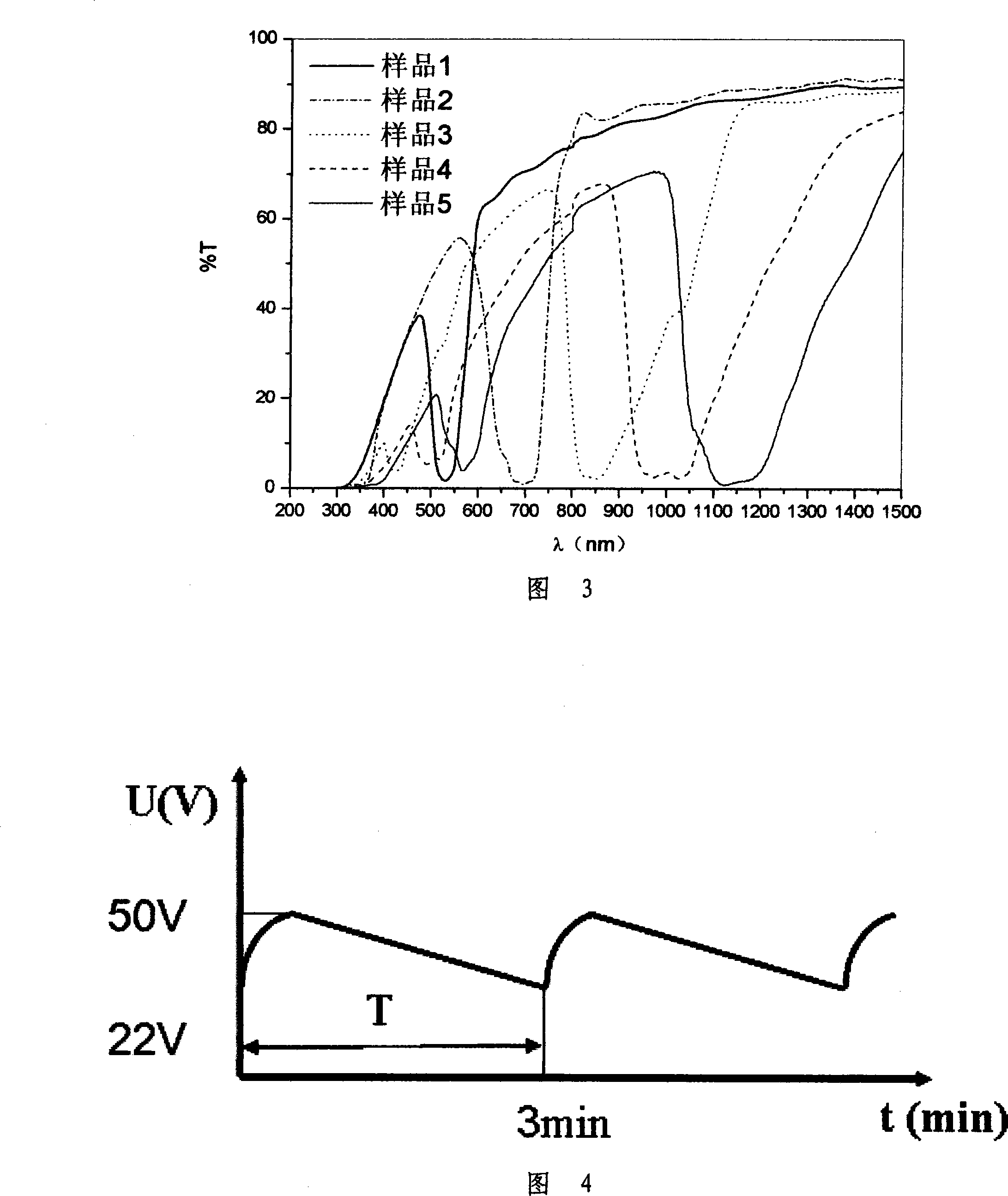

[0022] Embodiment 1: Complete the preparation in sequence according to the following steps: the aluminum sheet is placed in an acid solution with a concentration of 0.2M, and Figure 4 The arc tooth wave voltage is anodized for 20 hours; the purity of the aluminum sheet is 99.99%, the acid solution is oxalic acid solution, the amplitude of the arc tooth wave voltage is 22V, the wave front is 45 degrees, and the wave period is 3.5min. made approximately figure 1 with figure 2 as shown image 3 The sample 5 in the curve shows a porous aluminum oxide film filter with a bifurcated hole, the thickness of the main layer is 400nm, and the thickness of the bifurcated layer is 70nm.

Embodiment 2

[0023] Embodiment 2: Complete the preparation in sequence according to the following steps: the aluminum sheet is placed in an acid solution with a concentration of 0.25M, and Figure 4 The arc tooth wave voltage is anodized for 19 hours; the purity of the aluminum sheet is 99.9%, the acid solution is oxalic acid solution, the arc tooth wave voltage amplitude is 29V, the wave front is 45 degrees, and the wave period is 3min. made approximately figure 1 with figure 2 as shown image 3 The sample 4 in the curve shows a porous aluminum oxide film filter with bifurcated holes, the thickness of the main layer is 350nm, and the thickness of the bifurcation layer is 60nm.

Embodiment 3

[0024] Embodiment 3: Complete the preparation in sequence according to the following steps: the aluminum sheet is placed in an acid solution with a concentration of 0.3M, and Figure 4 The arc tooth wave voltage is anodized for 17 hours; the purity of the aluminum sheet is 99.99%, the acid solution is oxalic acid solution, the amplitude of the arc tooth wave voltage is 36V, the wave front is 45 degrees, and the wave period is 3min. made as figure 1 with figure 2 as shown image 3 The sample 3 in the curve shows a porous aluminum oxide film filter with a bifurcated hole, the thickness of the main layer is 300nm, and the thickness of the bifurcation layer is 60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com