Full plastic closestool

A toilet, polypropylene plastic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

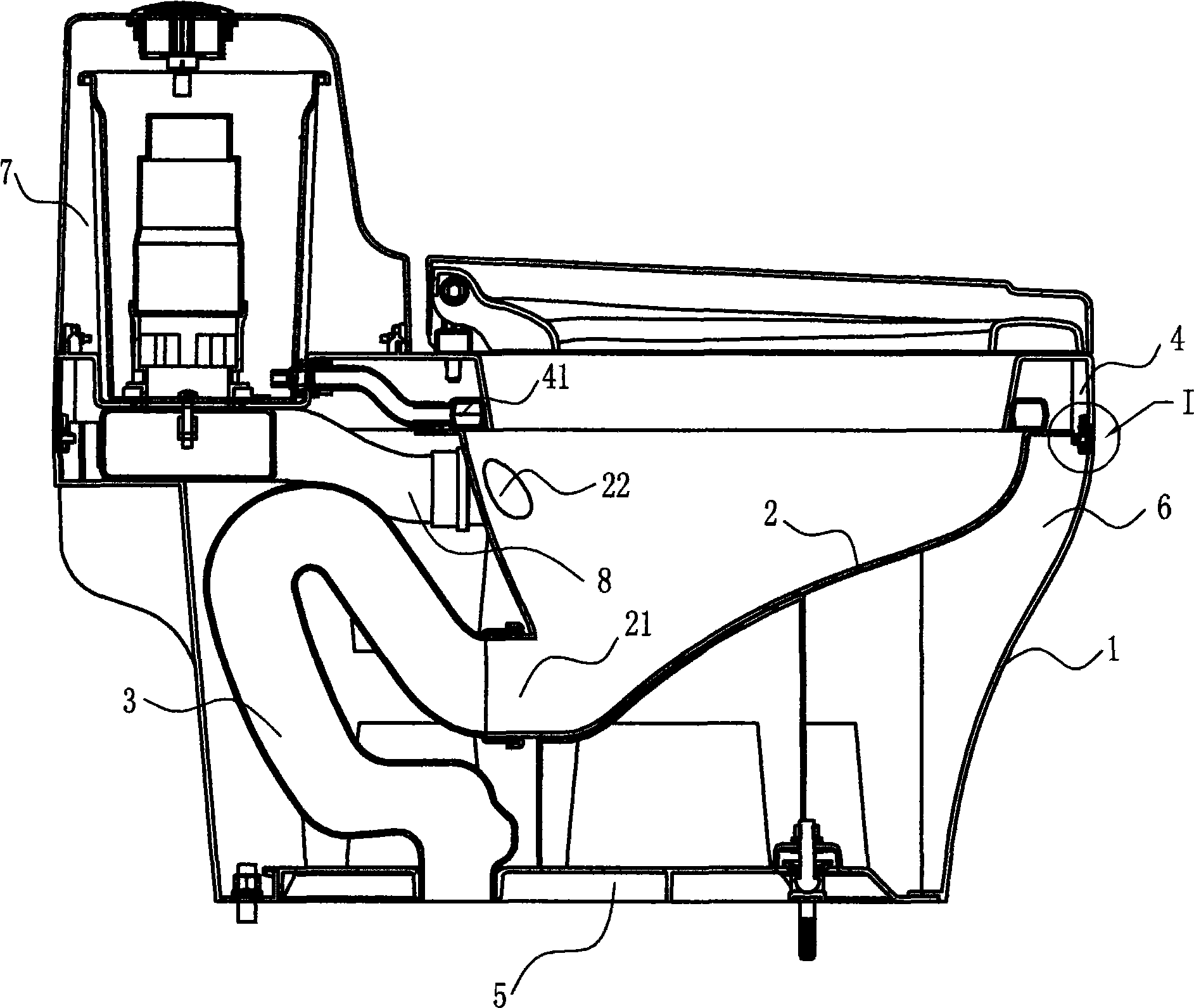

[0031] like figure 1 As shown, the all-plastic toilet includes:

[0032] The base main body 1, the base main body 1 is open up and down and the interior is hollow; the inner tank 2 is fixedly installed in the base main body 1, and the inner tank 2 is provided with a sewage outlet 21, and the inner tank 2 is also provided with main flush nozzle 22;

[0033] A siphon 3, one end of the siphon 3 is connected to the sewage outlet 21 of the liner 2, and the other end of the siphon 3 is an interface connected to the sewer pipe;

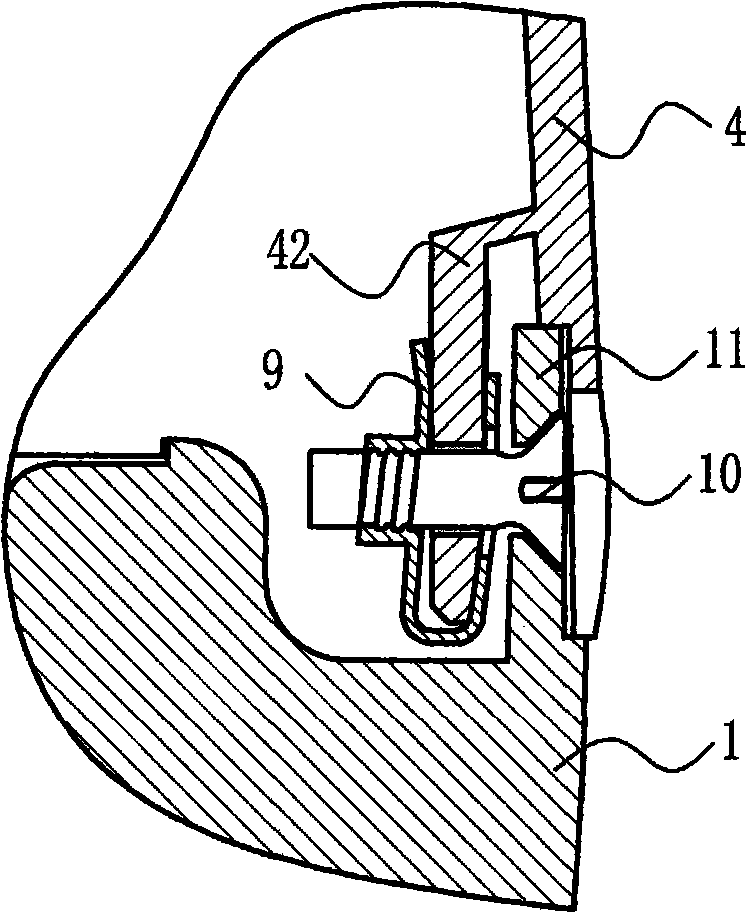

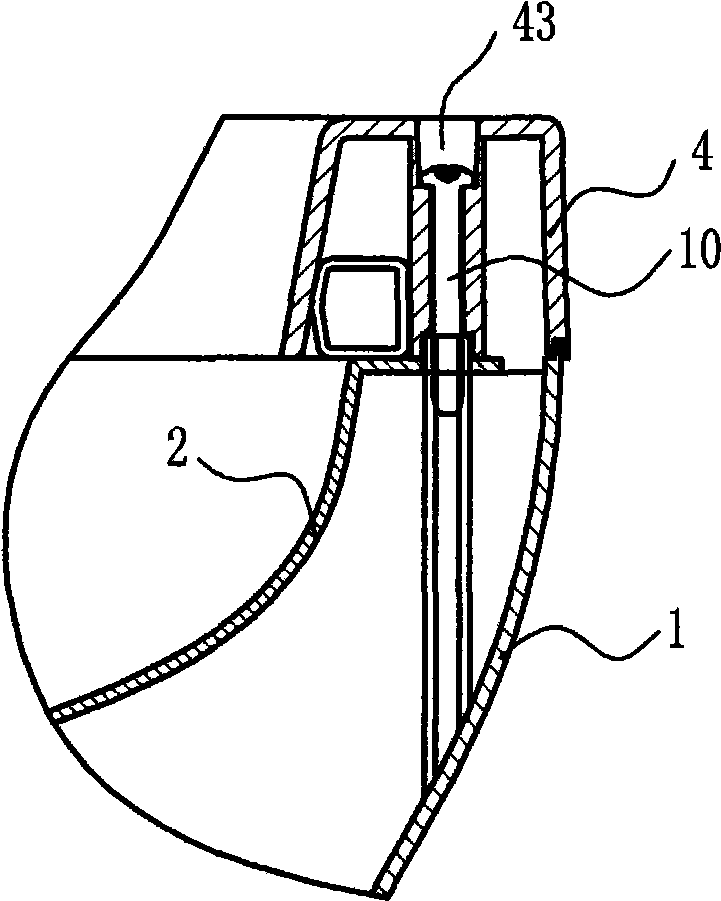

[0034] The base upper cover 4 is fixedly mounted on the upper end surface of the base main body 1 and the inner container 2, the base upper cover 4 has a defecation opening, and a cover, a seat, etc. are arranged between the base upper cover 4 and the base main body 1. Fixing device; the base upper cover 4 is provided with a side wall outlet pipe 41 around the defecation opening, and the side wall outlet pipe 41 is provided with a number of water outlets r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com