Electric melting explosion special-shaped deep hole machining electrode

A technology of special-shaped holes and electrodes, which is applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., and can solve the problems of difficult electrode production, rough and long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The processed special-shaped hole is an irregular elliptical hole, such as figure 1 shown.

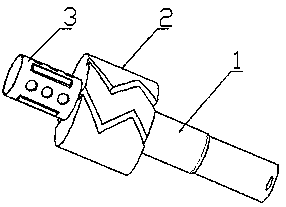

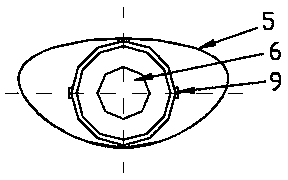

[0032] In this embodiment, the electrode for machining special-shaped deep holes by electric melting explosion includes a connecting section 1 of the cutter bar, a section 2 for processing the electrode round hole, and a section 3 for processing the electrode special-shaped hole; 1. It is connected sequentially by threads from top to bottom, and the center is provided with a chip removal hole 6 that runs through from bottom to bottom; the connection of each section is tight and reliable, such as figure 2 and 3 shown.

[0033] The above-mentioned electrode connection section 1 is located at the bottom of the electrode, and its outer wall is a stepped columnar shape. External threads are provided on the circumference of the lower end of the stepped columnar shape, and internal threads are provided on the circumference of the upper inner wall. The thread is connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com