Electrochemical sensor with interdigitated microelectrodes and conductive polymer

A conductive polymer, microelectrode technology, applied in scientific instruments, electrical solid devices, instruments, etc., can solve the problems of difficult to obtain data reproducibility, high dependence, increased difficulty and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059]sensor manufacturing

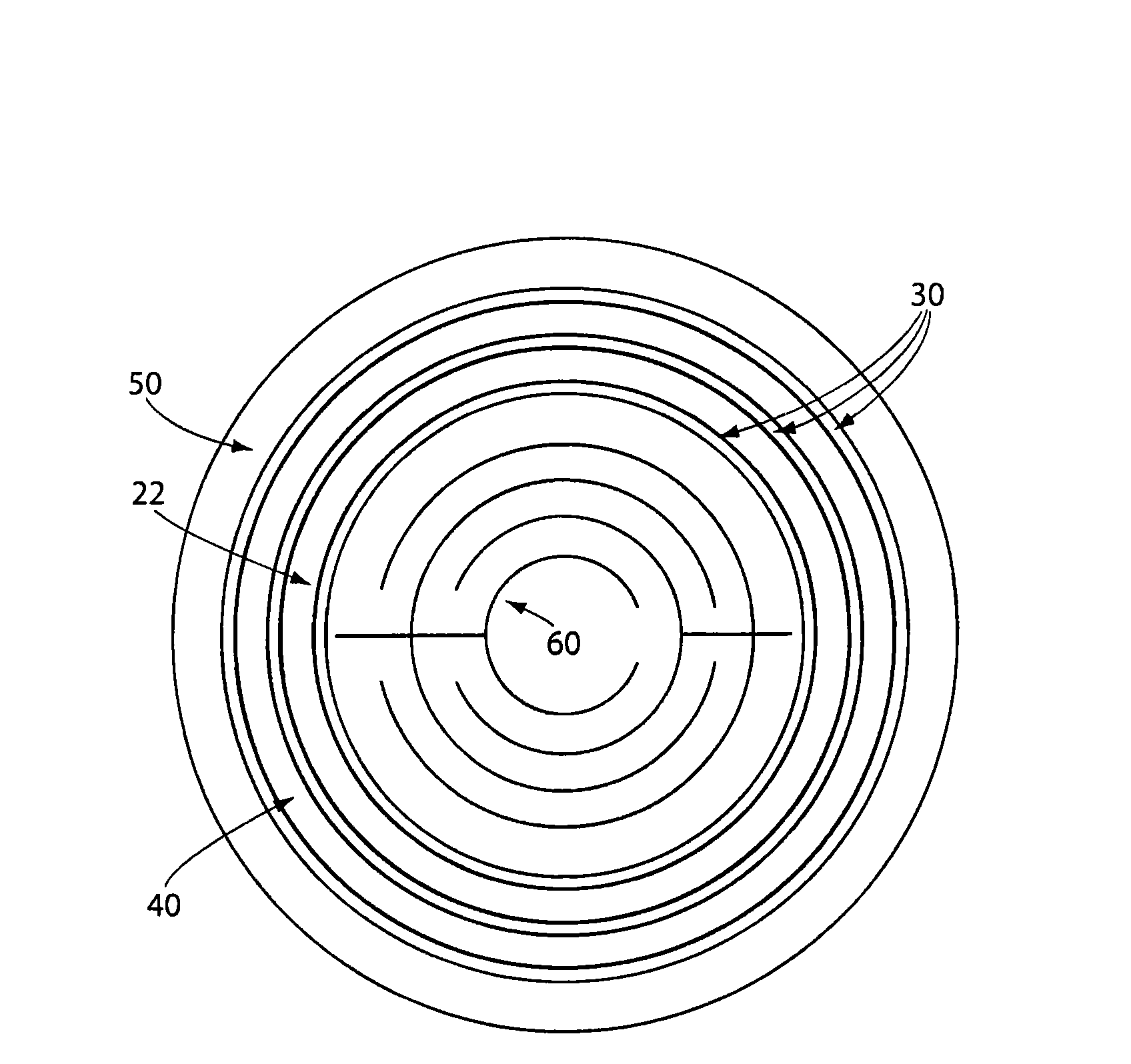

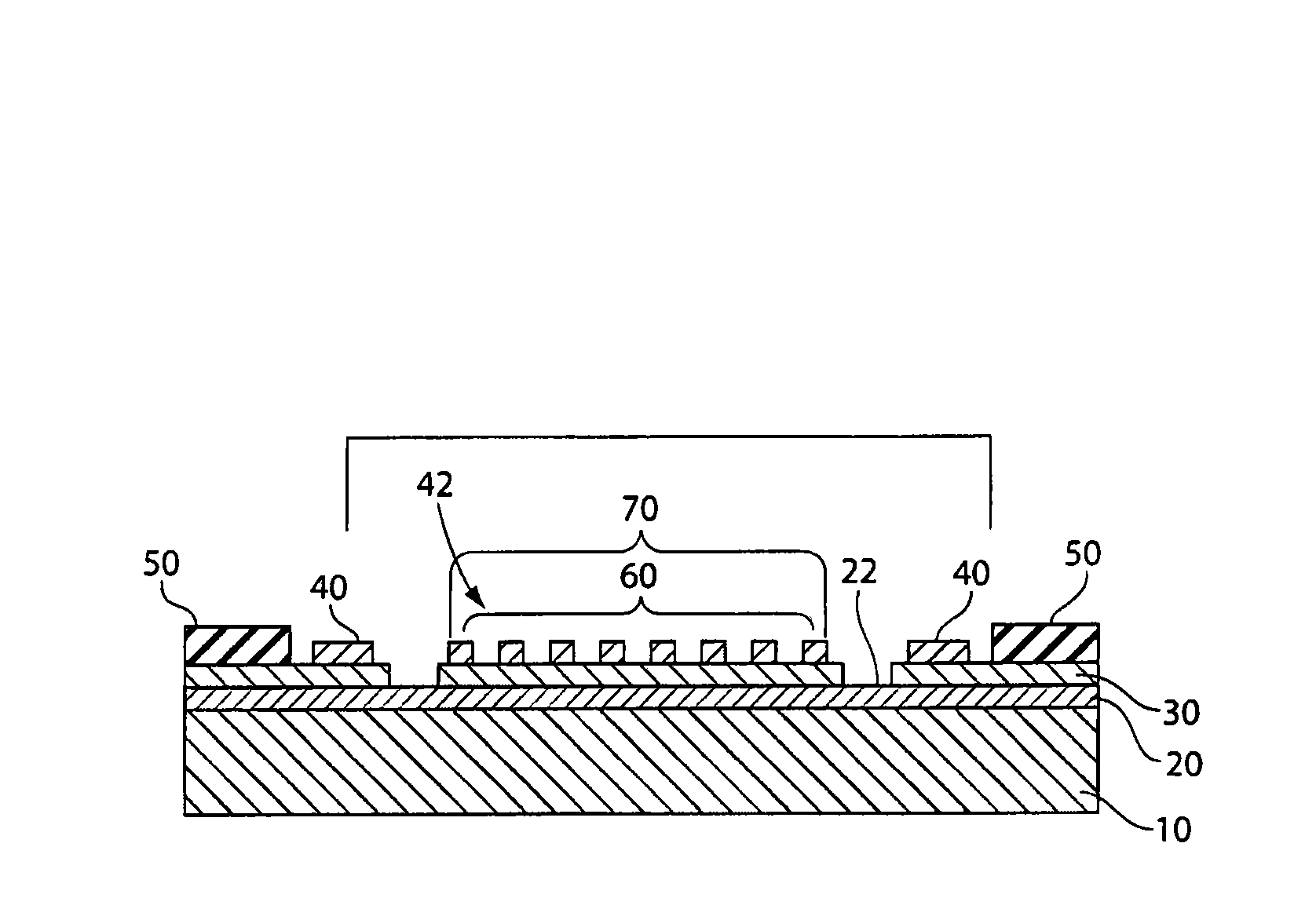

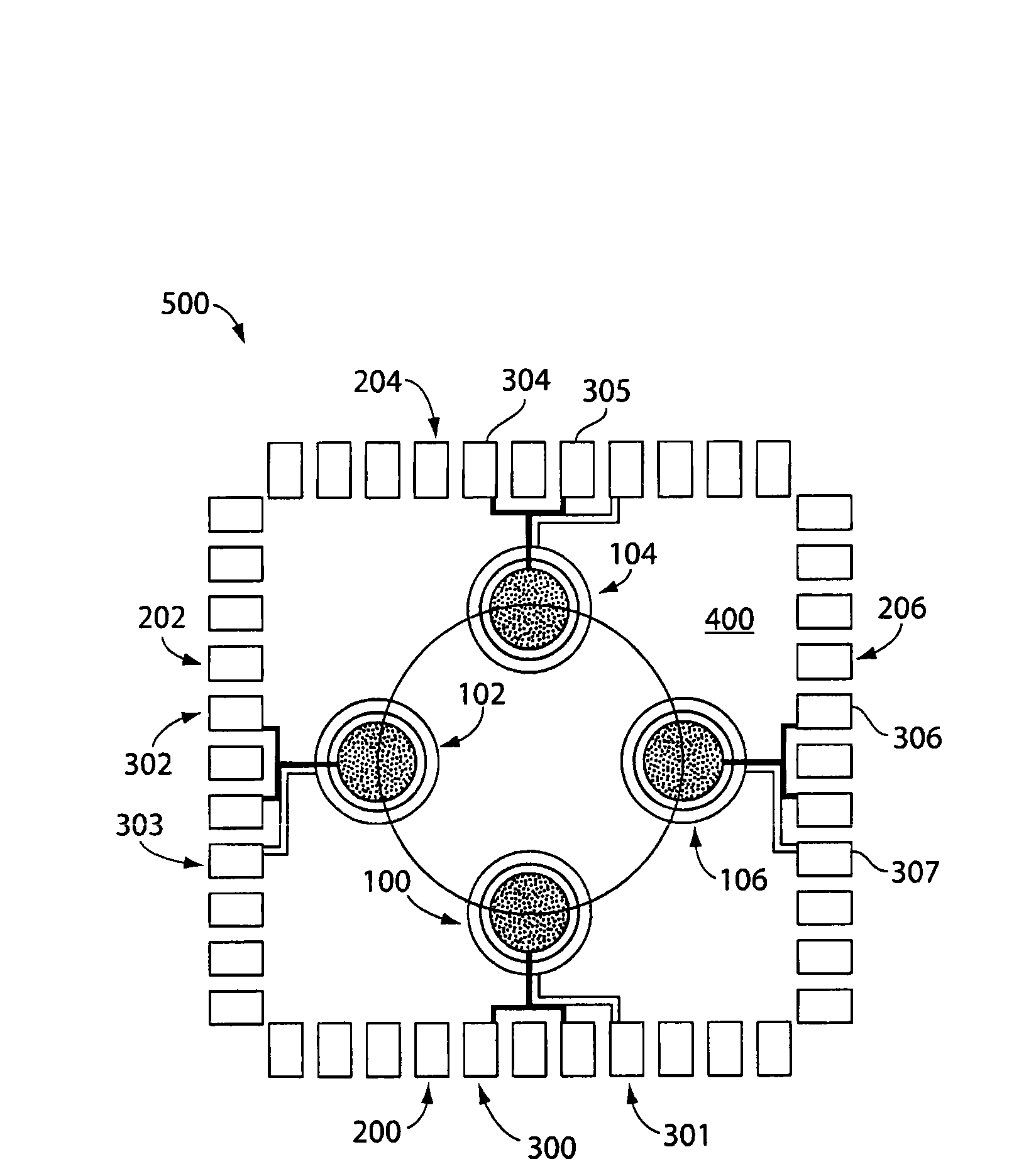

[0060] Fabrication of electronic devices with circular geometry components for droplet based electropolymerization and sensor applications, symmetrical reference and counter electrodes for electric field uniformity, and confinement of aqueous and organic based droplets The perfluorocarbon-based hydrophobic material formed by the two. image 3 A photograph showing a device containing four independent electronic sensors, each capable of confining a sample volume of 4 microliters within a 3 mm diameter hydrophilic region. The device can be applied to the development of new conductive materials and resistivity-based sensors.

[0061] A Pyrex 7740 wafer with a diameter of 4" was used as the substrate. After cleaning in piranha solution, a 10 nm thick layer of chromium and a 500 nm thick layer of silver were deposited by electron beam evaporation. A 1 μm thick low-stress silicon nitride film deposited by chemical vapor deposition (PECVD) was used to co...

Embodiment 2

[0064] sensor test

[0065] The sensor device design has two functions: (1) Electropolymerization and material deposition from one droplet (e.g. <10 μL) of a monomer solution of a conjugated compound, including pyrrole, aniline, Thiophene, nathiophene, ethylenedioxythiophene and their derivatives, and (2) as electrochemical cells for the characterization, testing and application of materials as-deposited from one solution droplet (eg <10 μL). Devices with perfluorocarbon surface coatings can be used for both aqueous and non-aqueous droplets.

[0066] First, the cyclic voltammograms of ferrocene (in organic solution) and ferricyanide (in aqueous solution) were measured to test the system. Figure 5 nBu shown at 0.1 M 4 NPF 6 Cyclic voltammogram of a droplet (5 μL) of ferrocene solution in propylene carbonate in the presence of It is observed that at 0.2V there is a half-wave potential (E 1 / 2 ) reversible wave. The device uses an Ag wire as a reference electrode and is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com