Targa roof system with a buttress

A pillar and roof technology, applied to roofs, vehicle components, transportation and packaging, etc., can solve problems such as lack of protective roll bars, blocked air vents, and endangering the overall safety of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

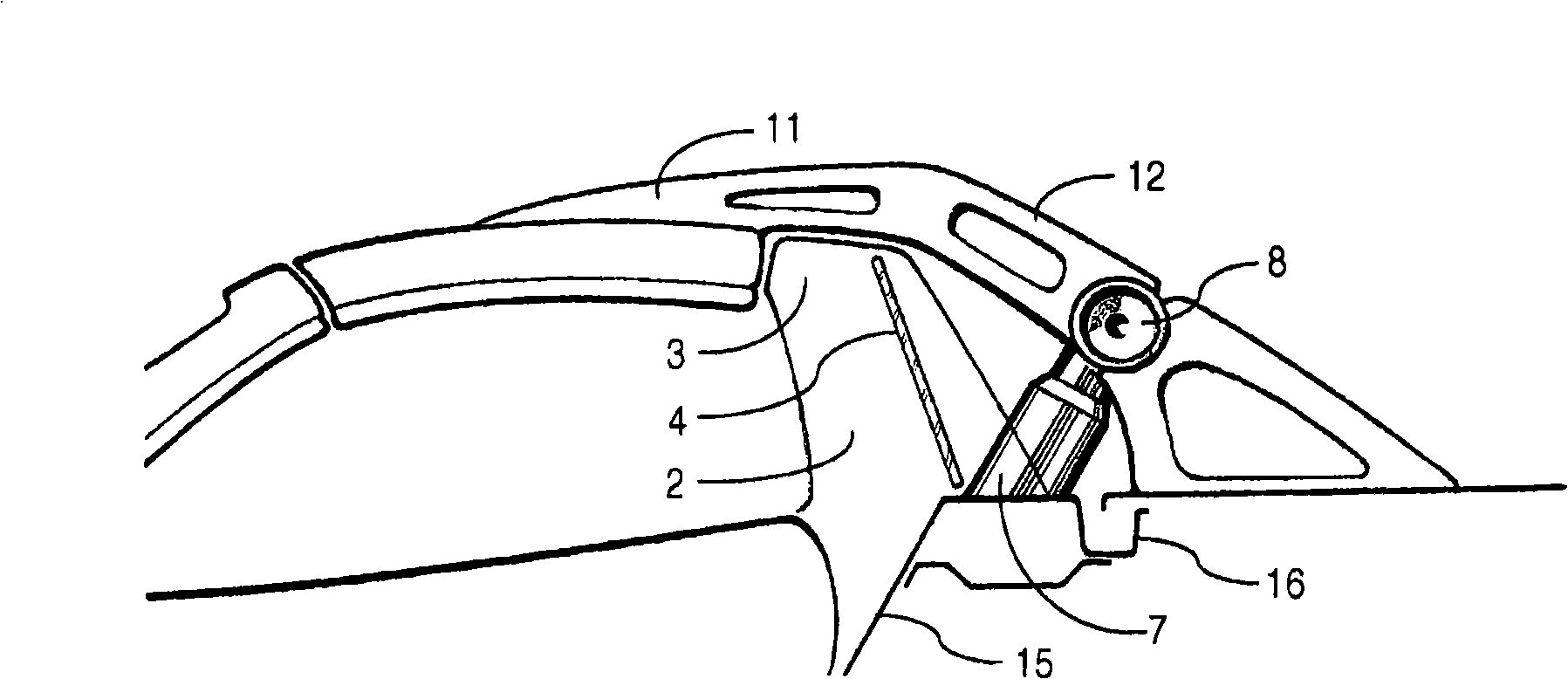

[0022] Such as figure 1 and 2 The basic system is shown with a front window upper frame 1 , a pair of side pillars 2 supporting a roll bar 3 , a non-pivoting rear window 4 , and a single pivoting roof panel 6 . The roof panel 6 is hinged to a centrally mounted strut 7 via a swing arm 9 and a strut pivot 8 .

[0023] This system is suitable for cars with mid-engine design. The central strut 7 is incorporated into the structural rear window 4 which supports a pivot 8 . The struts 7 also serve as transparent air ducts with air intakes above the roll bar 3 in the cover 12 and the elongated segments 10 of the swing arms 9 are integral reinforcing parts of the composite roof structure. They adjoin the left and right sides of the pillar 7 and form air-guiding ribs on the roof surface. The tilt bracket 11 rotates the roof panel 6 rearwardly about 180° to an up-side-down position on top of the decklid 5 and further back from the rear window 4 . Advantageously, with this arm geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com