Development roller, development device, image forming apparatus, and method of manufacturing development roller

A manufacturing method and a technology of a developing device, which are applied in the direction of the electric recording process using the charge pattern, the equipment of the electric recording process using the charge pattern, and liquid chemical plating, can solve the problems such as difficult to maintain image density and difficult to develop, and achieve Effects of suppression of toner coverage, good development, and suppression of decline in toner chargeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

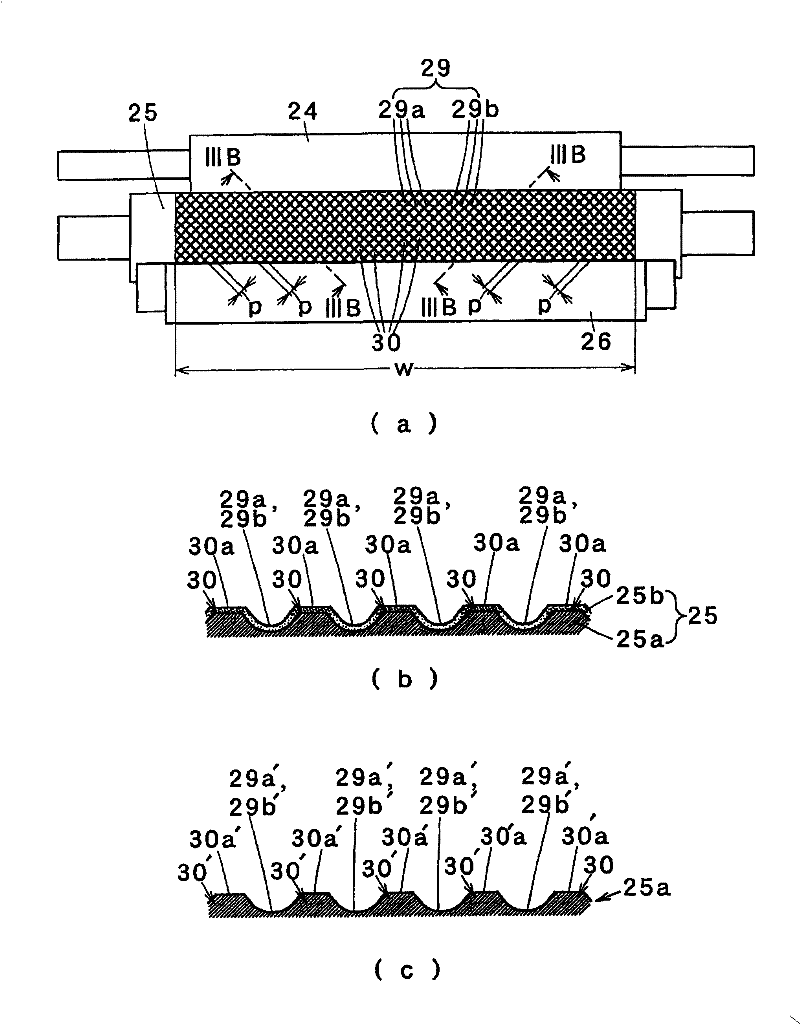

[0054] Such as image 3 As shown in (a), on the outer peripheral surface of the developing roller 25 , similar to the developing roller described in the above-mentioned Patent Document 1, a mesh-like concave-convex pattern is formed. In the developing roller 25 of this example, grooves 29 are formed over the entire periphery at predetermined positions in the axial direction on the outer peripheral surface as the concave-convex pattern. At this time, the groove 29 is formed in a helical shape successively inclined at a predetermined angle (in the illustrated example, 45°, but not limited thereto) with respect to the axial direction of the developing roller 25 and has a predetermined number of regularities. One slanted groove 29a and a predetermined number of second slanted grooves 29b are formed successively in a helical shape inclined oppositely to the inclination of the first slanted grooves 29a. These first and second inclined grooves 29a, 29b are formed at intervals p at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com