Thick steel plate for pressure vessel, method for manufacturing the same, use of the same

A technology for a pressure vessel and a manufacturing method, applied in the field of iron and steel materials, can solve problems such as not being able to fully meet actual needs, and achieve the effects of facilitating the implementation of a heat treatment process, excellent low-temperature impact toughness, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

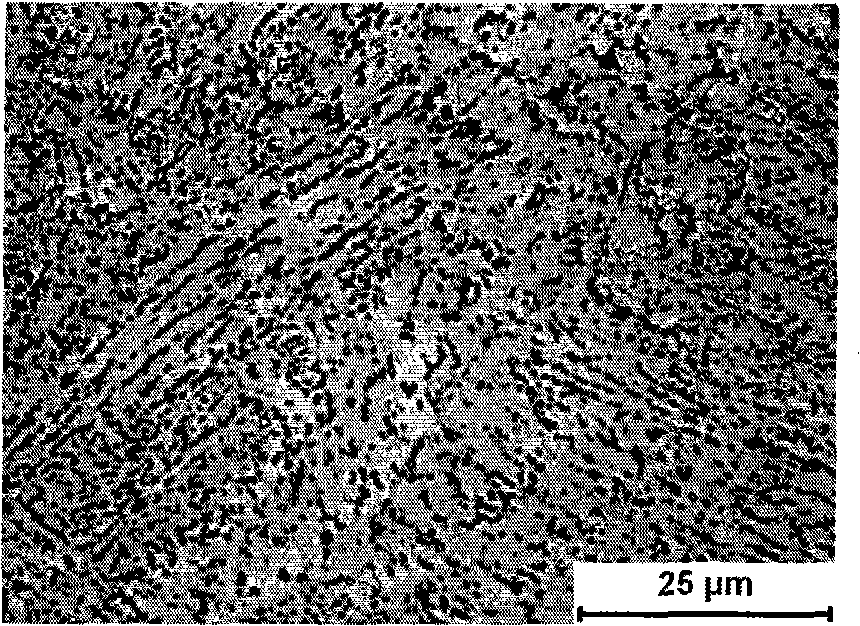

Image

Examples

Embodiment 1

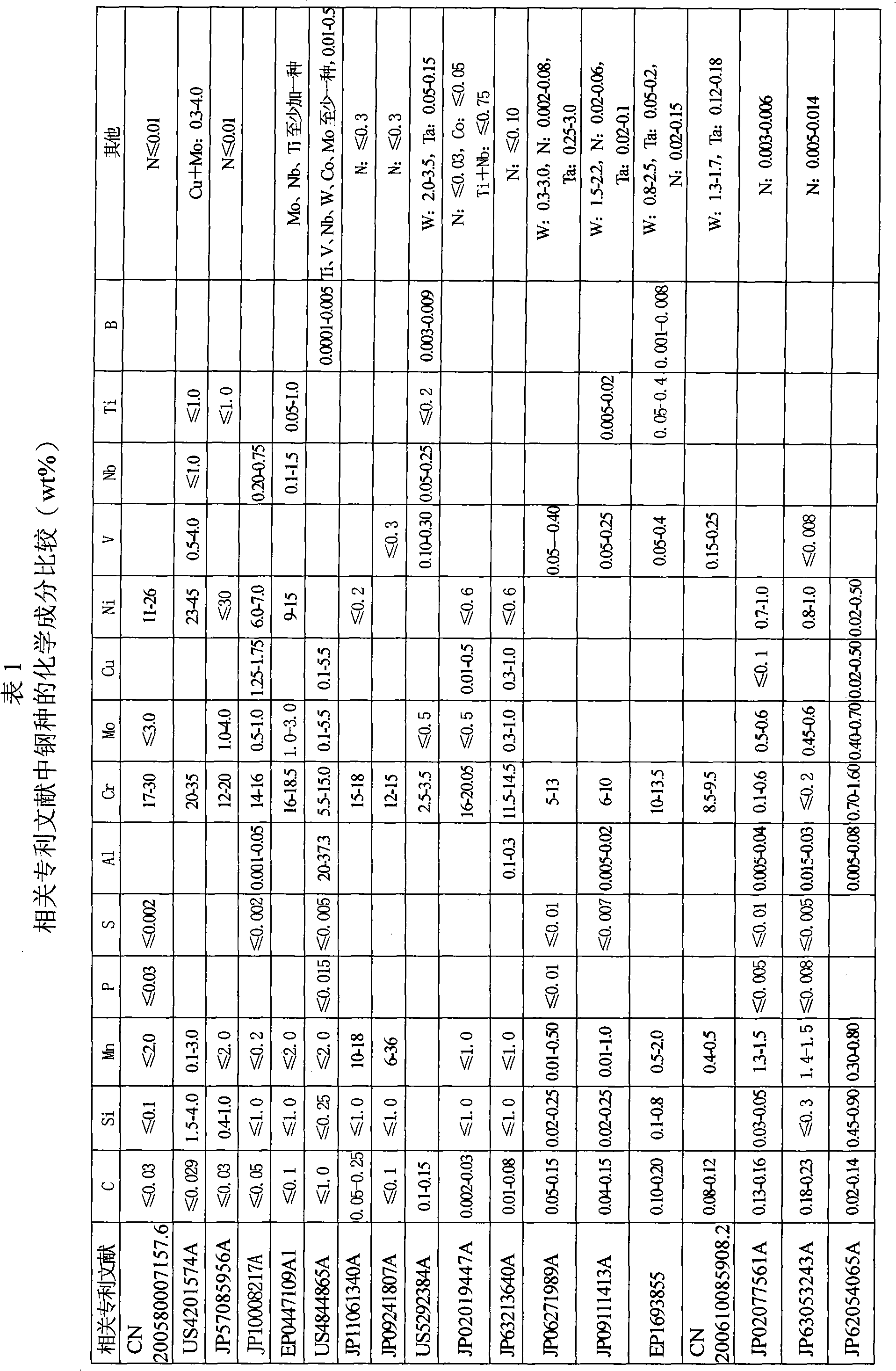

[0044] It is smelted according to the chemical composition shown in Table 2, cast into billets, and hot-rolled at 1100-1250° C., and the hot-rolling deformation is >80%. After rolling, heat-treat the steel plate, heat it at 910°C and keep it warm, then immediately spray water to quickly cool it to below 200°C, and then temper it at 640°C. The thickness of the finished steel plate is 40mm.

Embodiment 2

[0046] The implementation mode is the same as that in Example 1, wherein the heating temperature during the heat treatment is 930° C., the tempering temperature is 620° C., and the thickness of the finished steel plate is 20 mm.

Embodiment 3

[0048] The implementation mode is the same as that in Example 1, wherein the heating temperature in the heat treatment process is 890° C., the tempering temperature is 670° C., and the thickness of the finished steel plate is 70 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com