Method for removing trivalent arsenic ion and pentavalent arsenic ion in water and system thereof

A trivalent arsenic and pentavalent arsenic technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc. The effect of easy control, long service life and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

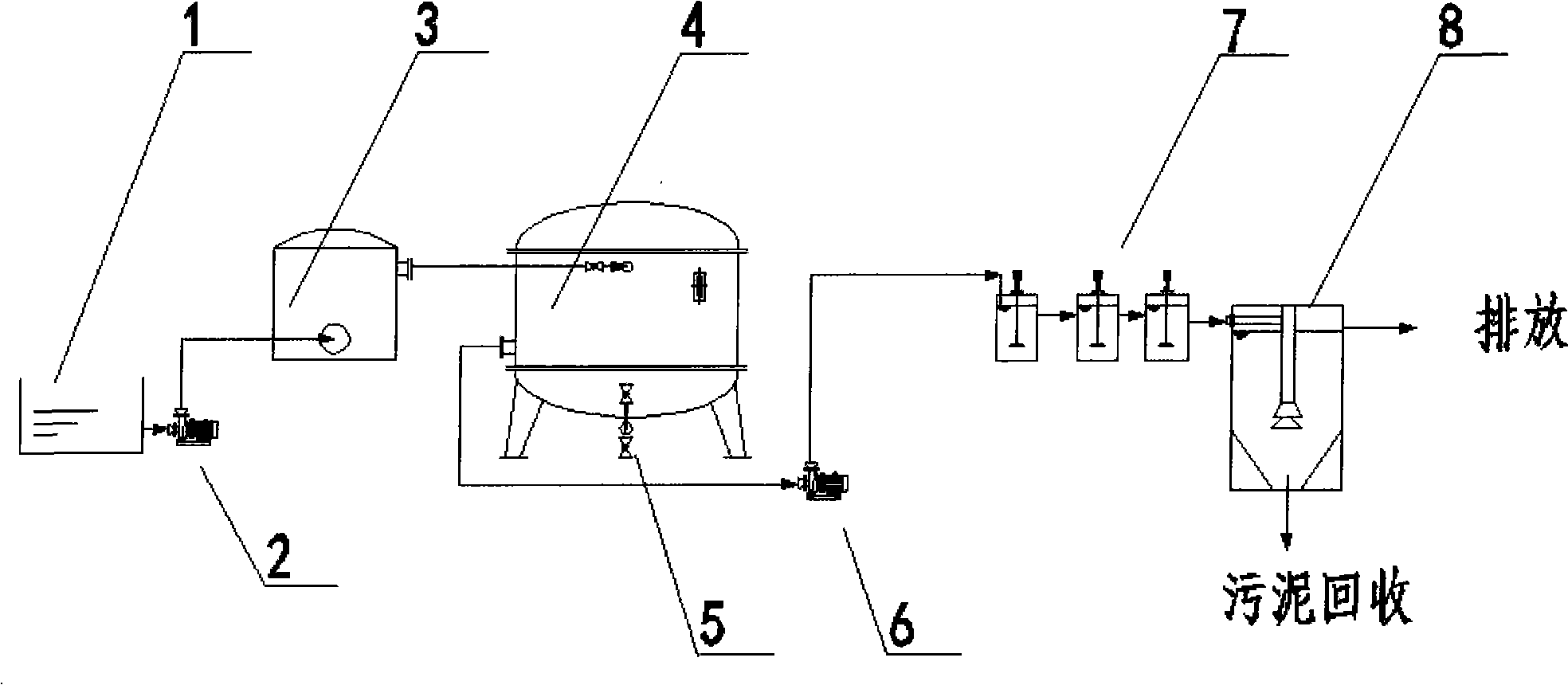

Image

Examples

example 1

[0030] 1. Use the internal tap water of an enterprise (the arsenic content is about 1mg / L), pass through the laminated filter (filtering precision is 200μm), remove the impurities in it, and then flow into the arsenic removal tower.

[0031] 2. Carry out adsorption to remove arsenic, the adsorption flow rate is 30BV / h, and the effluent is discharged up to the standard.

[0032] 3. When the arsenic content in the effluent reaches the leakage control point, the nano-adsorbent is desorbed, and a 3% NaOH+3% NaCl mixture is used for desorption.

[0033] 4. The desorption liquid is sent to the secondary coagulation tank, the pH value is 1, and the coagulant is iron oxide (the dosage is 5 times that of the arsenic content). After coagulation, it enters the sedimentation tank for separation.

[0034] The treatment of arsenic-containing water by nano-adsorbent can make the arsenic content below 0.01mg / L (10ppb), and maintain it until adsorption saturation. After repeated adsorption an...

example 2

[0041] 1. Use the arsenic-containing water inside the beverage company, pass through a laminated filter (filtering precision is 400 μm), remove the impurities in it, and then flow into the arsenic removal tower.

[0042] 2. Carry out adsorption to remove arsenic, the adsorption flow rate is 20BV / h, and the effluent is discharged up to the standard.

[0043] 3. When the arsenic content in the effluent reaches the leakage control point, the nano-adsorbent is desorbed, and a 4% NaOH + 5% NaCl mixture is used for desorption.

[0044] 4. The desorption solution is sent to the primary coagulation tank, the pH value is 4, the coagulant is PAM (the amount is 9 times of the arsenic content), and after coagulation, it enters the sedimentation tank for separation.

[0045] The treatment of the arsenic-containing water by the nano-adsorbent can make the arsenic content below 0.01 mg / L (10 ppb), which meets industrial application.

[0046] data and processing

[0047] Arsenic removal dat...

example 3

[0052] 1. Use the internal process water of an enterprise, pass through a regulated filter (filtering precision of 1 μm), remove impurities in it, and then flow into the arsenic removal tower.

[0053] 2. Carry out adsorption to remove arsenic, the adsorption flow rate is 10BV / h, and the effluent discharges up to the standard.

[0054] 3. When the arsenic content in the effluent reaches the leakage control point, the nano-adsorbent is desorbed, and a 5% NaOH + 3% NaCl mixture is used for desorption.

[0055] 4. The desorption liquid is sent to the three-stage coagulation tank, the pH value is 5, and the coagulant is iron oxide (the dosage is 10 times of the arsenic content), and after coagulation, it enters the sedimentation tank for separation.

[0056] The treatment of arsenic-containing water by nano-adsorbent can make the arsenic content below 0.01mg / L (10ppb), and maintain it until adsorption saturation. After repeated adsorption and desorption for five times, the adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com