An external flag staff lifter

A lifter, flagpole technology, applied in the direction of lifting device, building type, building, etc., can solve the problems of high production cost, complex structure, inconvenient maintenance, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

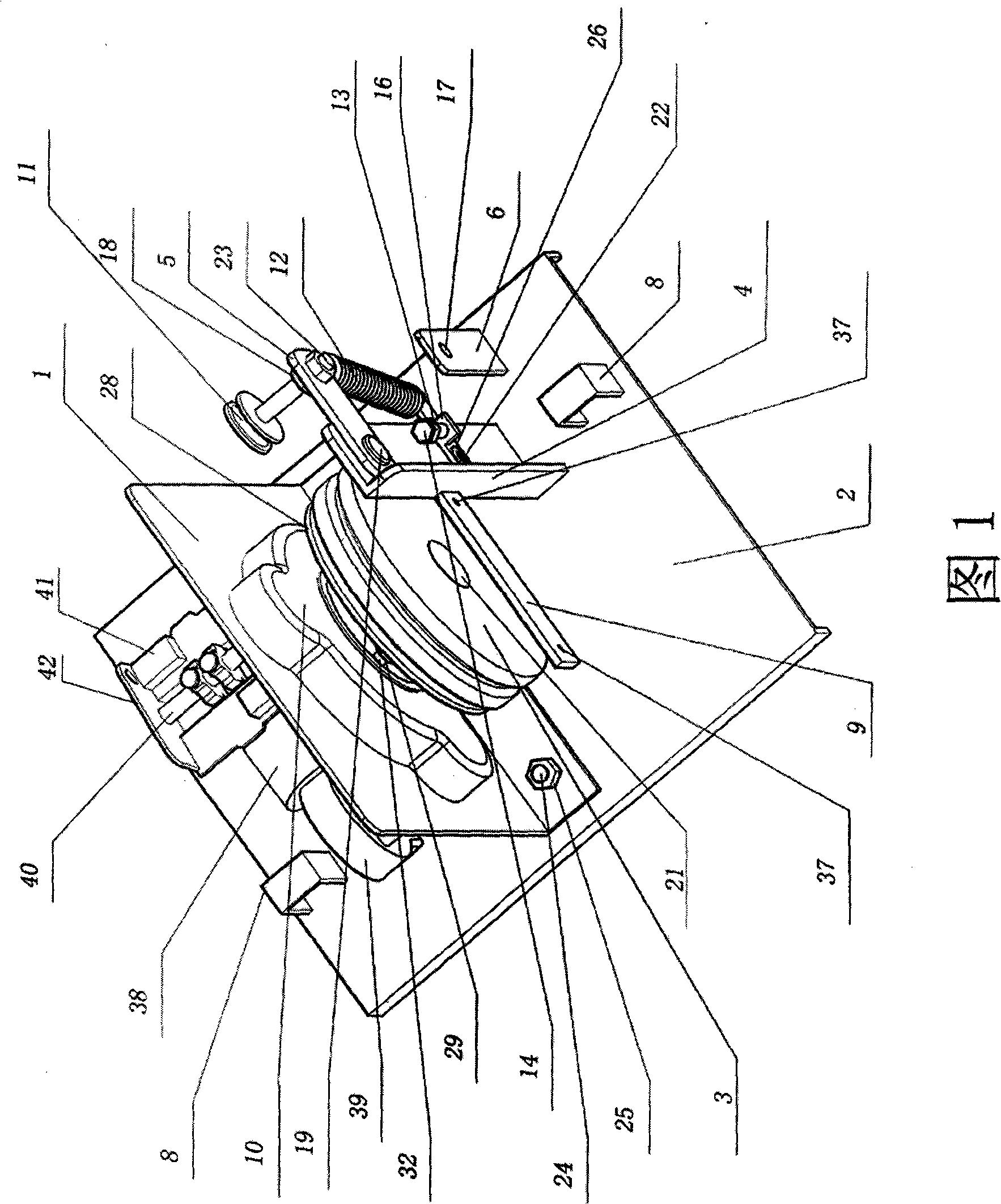

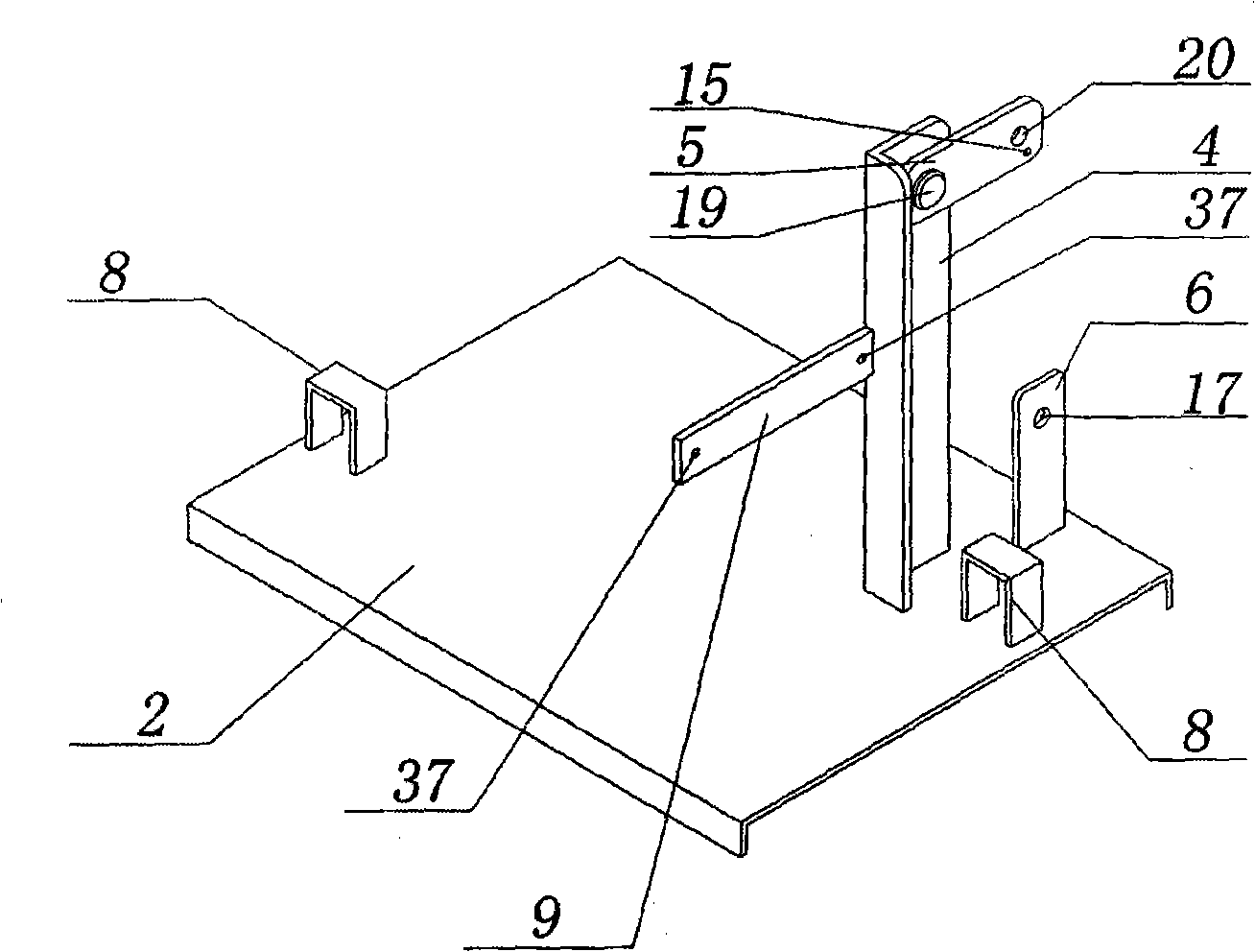

[0024] Such as figure 1 As shown, the bracket plate 1 is fixed to the middle of the base 2 with a fixing screw B24 and a fixing nut C25. Such as figure 2 , image 3 As shown, a fixing frame 4, a clutch frame 6 and two outer cover lock grooves 8 are also welded on the upper part of the base 2. Combine figure 1 , figure 2 , image 3 , Picture 11 As shown, a gear transmission structure is arranged inside the gear cover 10. The gear transmission structure consists of a central shaft gear 51 in the middle of the support plate 1 and a limit gear 50 fixedly meshing with the motor gear 53 in a clutch manner. The central shaft gear 51 is installed on the central shaft, and the central shaft is welded to the bracket plate 1. Such as Figure 4 , Figure 5 As shown, a fixed screw C30 is provided on the central shaft gear 51, a hole for passing through the fixed screw C30 is provided in the middle of the disc 28, and the disc 28 is locked with a fixed nut D29. The fixed screw D32 on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com