Method and control device for manufacturing product shell patterns

A production method and technology of a control device, which are applied in the process of producing decorative surface effects, decorative arts, engraving, etc., can solve the problems of high pattern production cost, complicated and time-consuming pattern production process, etc., and achieve simple design and simple circuit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

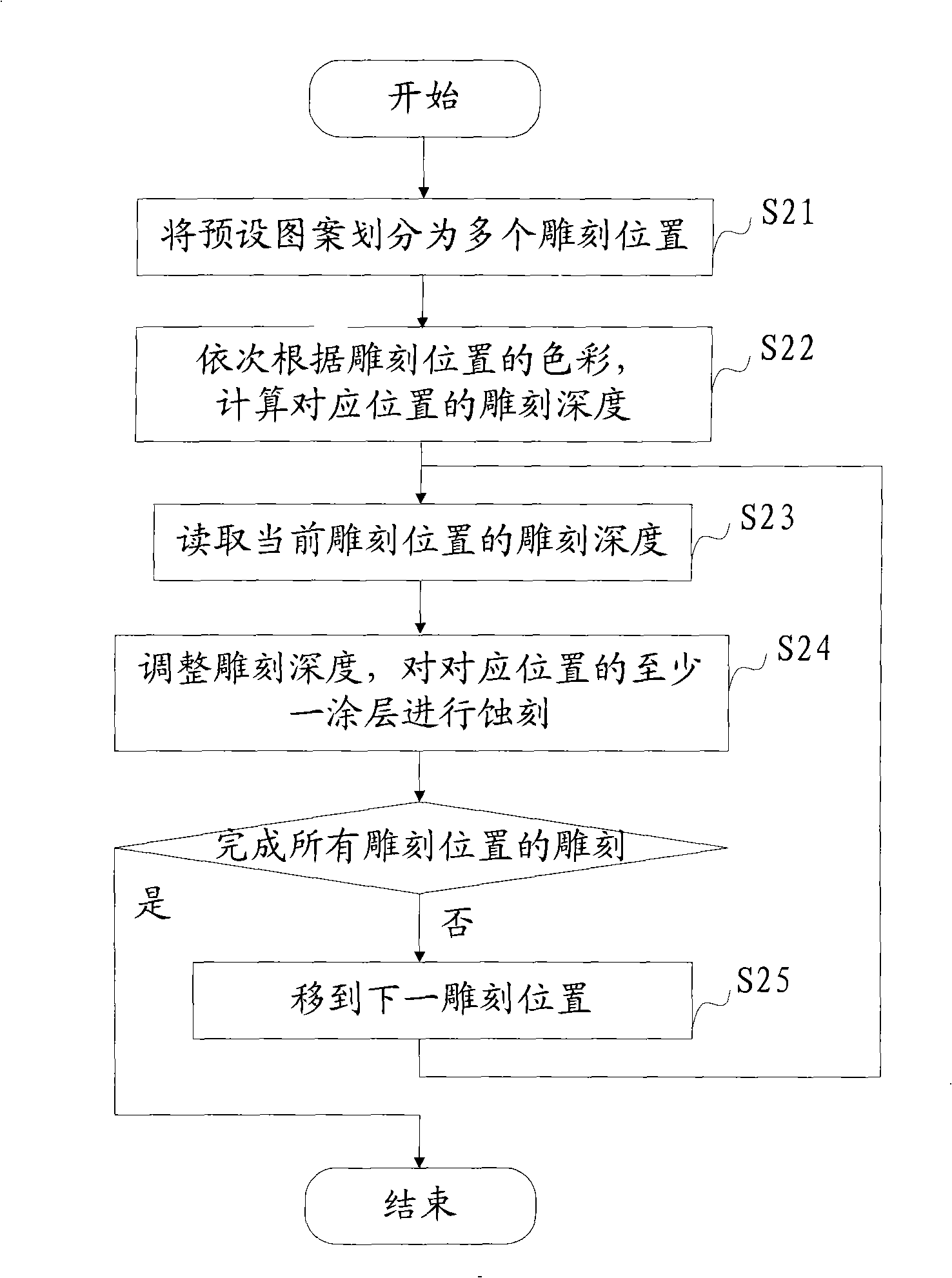

[0021] The present invention proposes a first embodiment, and the method for making a product shell pattern includes:

[0022] Step S11, setting an engraving scheme according to at least one coating attached to the product shell;

[0023] Step S12, jointly engraving the at least one coating layer according to the engraving scheme to obtain a pattern.

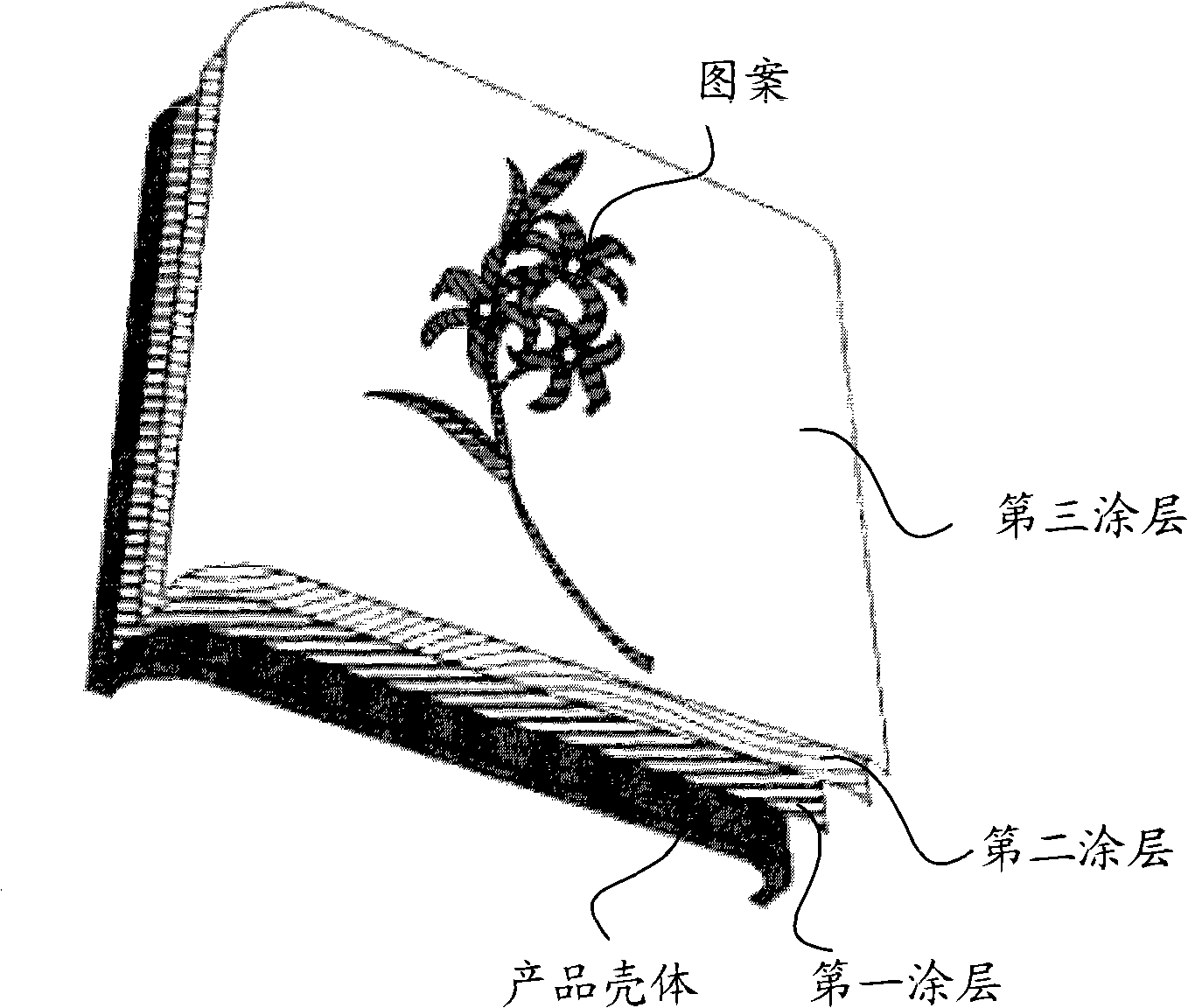

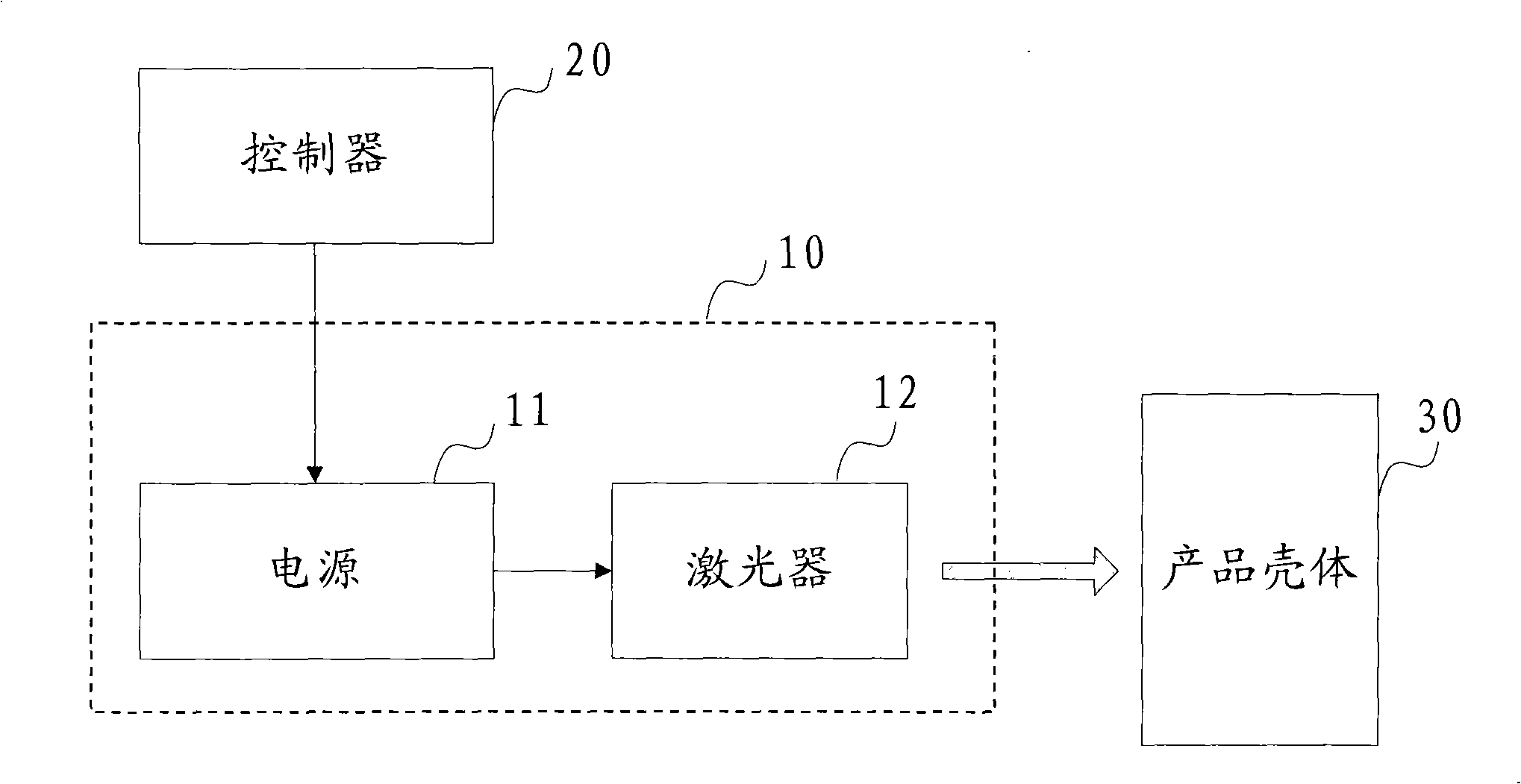

[0024] The product casing in the above step S11 can be attached with at least one coating by various techniques such as spraying and silk screen printing. The product casing can be made of various materials, and at least one coating can be of different colors. Step S12 can use laser engraving technology to engrave at least one coating together, etch away at least one coating, so that at least one coating and / or the product shell are partially exposed, and the exposed parts show different colors, and the combination realizes the product shell colorful pattern.

[0025] Based on the above-mentioned embodiment, the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com