Full paper packaging box of flat panel display and manufacturing method thereof

A flat panel display and manufacturing method technology, applied in the directions of carton/carton manufacturing machinery, packaging, transportation and packaging, can solve the problems of transportation occupation, complex processing procedures, environmental pollution by lining materials, etc., to save transportation space, surrounding The effect of uniform box wall and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention are described with reference to the above drawings.

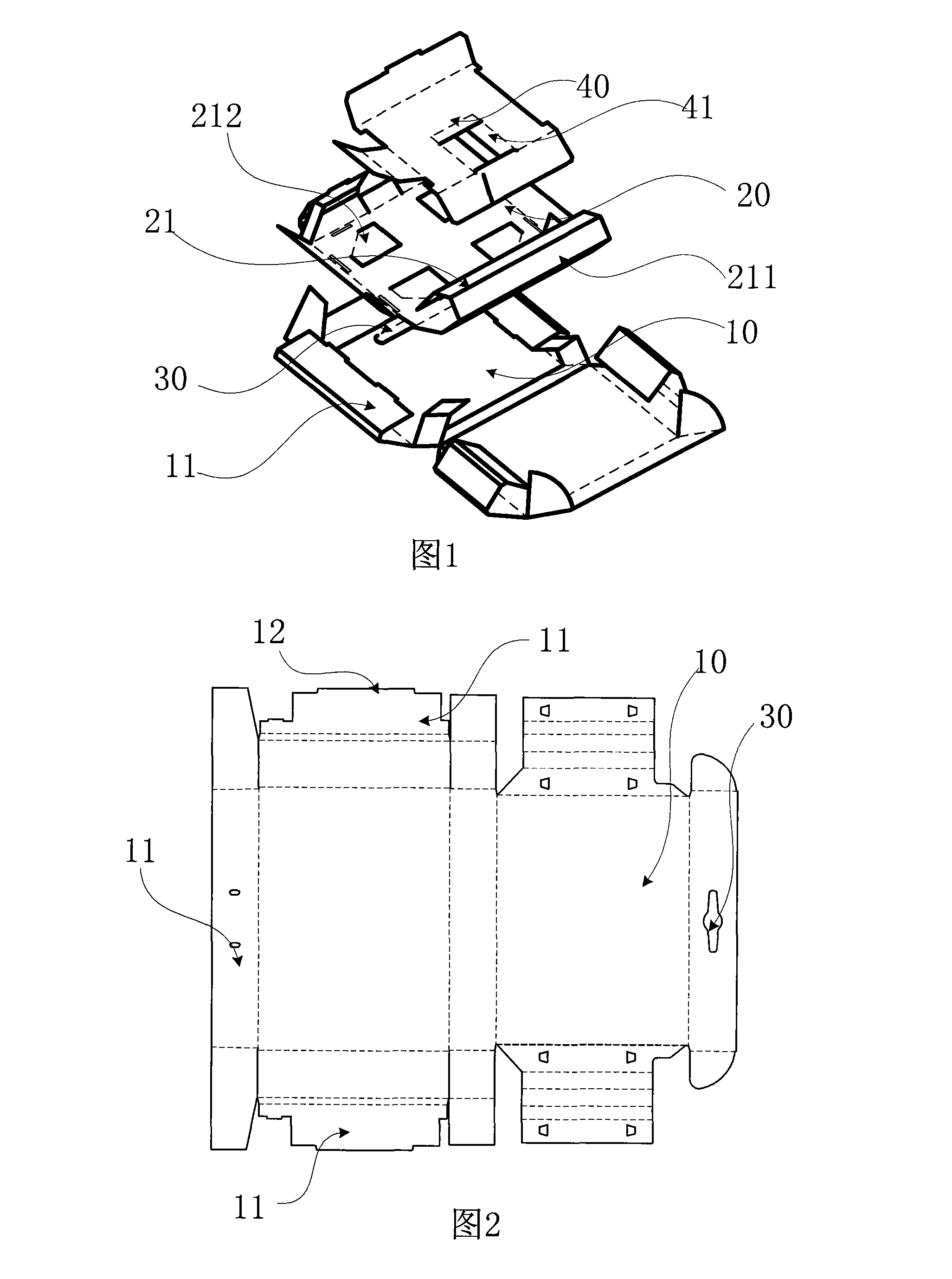

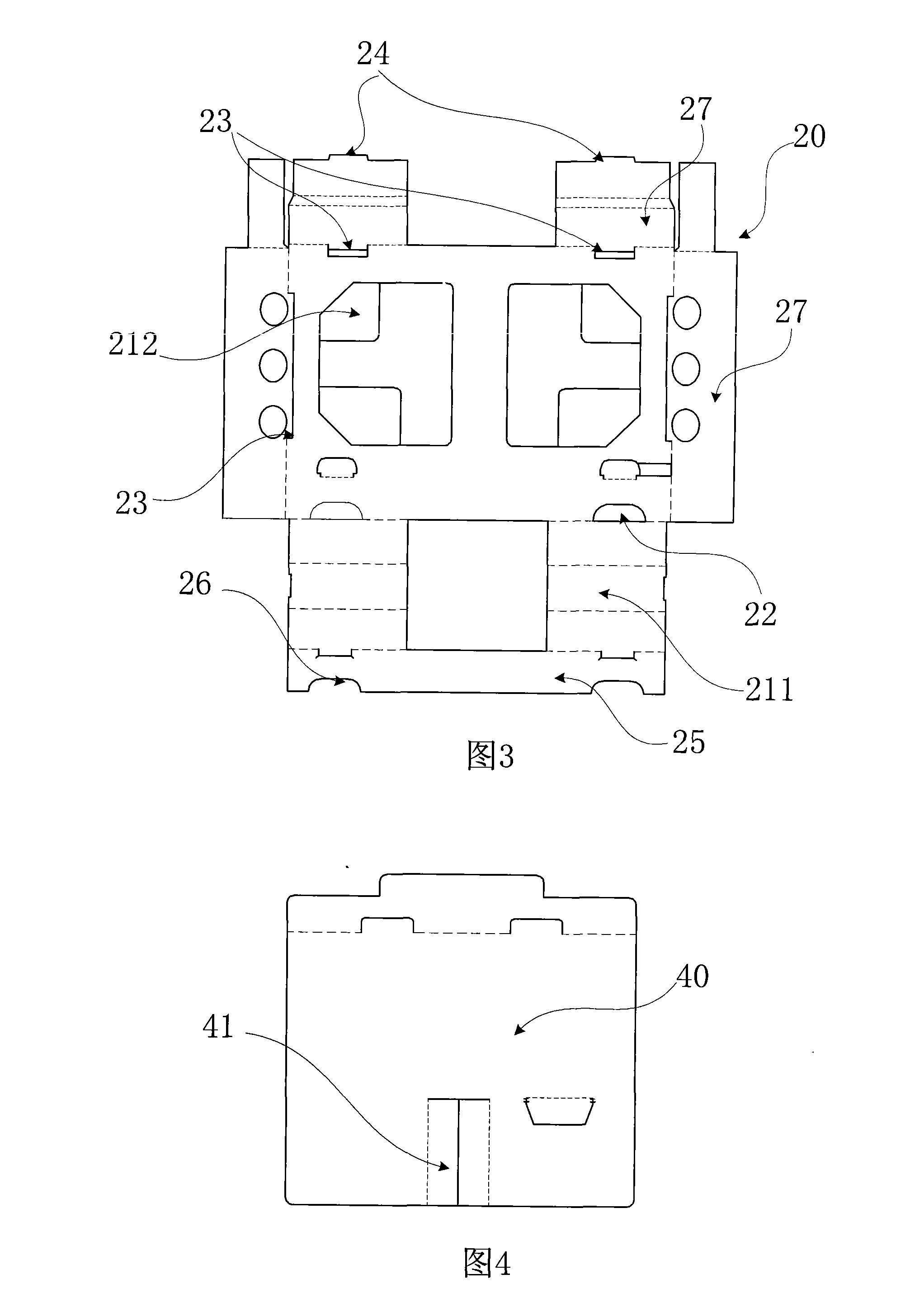

[0017] Depend on figure 1 It can be seen from the figure that the paper packaging box of this flat panel display includes a box body 10 folded and buckled into shape, and a bottom liner plate 20 placed in the box body 10, and the bottom liner plate 20 is partially folded into a raised limit stop. The file 21, the box body 10 is provided with a handle hole 30. The packaging box of the present invention is made of all paper materials, wherein the support of the side wall of the box body and the inner isolation liner are all folded by the box body itself and the inner liner board. The unique plastic handle can not only ensure the use of all paper materials, but also can be formed at one time during the cardboard processing process, saving the cost of traditional isolation liner materials, and at the same time, it can also reduce the space occupied during transportation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com