Method and apparatus for bonding wafer

A chip and bonding technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low chip strength, poor chip-to-chip sealing, high damage rate, etc., to improve sealing, improve full dissolution and Uniform penetration and strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

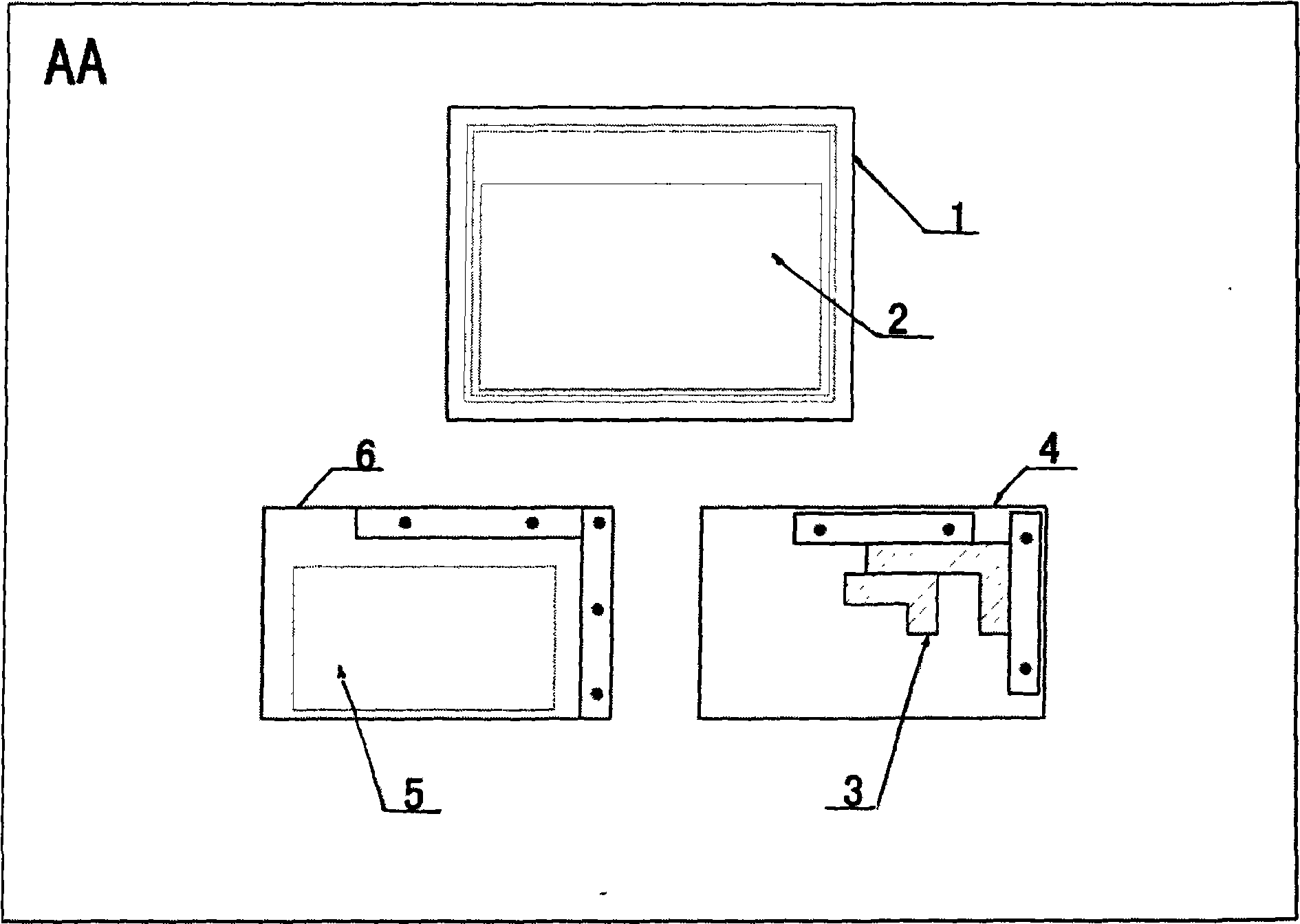

Image

Examples

Embodiment 1

[0021] Embodiment 1, chip 25MHZ (chip model HC-49U / S)

[0022] 1. Configuration of glue for bonding wafers: 0.5kg of ozokerite 85, 0.3kg of rosin, and 0.5kg of hot melt adhesive are mixed and put on the heating plate in the aluminum pot for heating. The power of the heating plate is 1000W to make the ceresin and rosin . After the hot melt adhesive is fully melted, stir it. After stirring evenly, filter the glue solution with a 60-mesh metal filter and put it into a 30cm×50cm tray;

[0023] 2. Baking of the bonded wafer: put the wafer into the tray in the electric oven, the temperature of the electric oven is 170°C, and the baking time is 35 minutes;

[0024] 3. The fixture frame 4 on the heating plate of the electric furnace B and the movable fixture 3 on the fixture frame 4 are preheated: the preheating temperature is 30°C;

[0025] 4. Put the configured glue on the heating plate of the electric furnace A and heat it. The temperature of the melted mixed glue is 140°C;

[00...

Embodiment 2

[0029] Embodiment 2, chip 20MHZ (chip model HC-49U / S)

[0030] 1. Configuration of glue for bonding wafers: 0.2kg of ozokerite 85, 0.12kg of rosin, and 0.2kg of hot melt adhesive are mixed and placed on a heating plate in an aluminum pot to heat. The power of the heating plate is 1000W, so that ceresin and rosin . After the hot melt adhesive is fully melted, stir it. After stirring evenly, filter the glue solution with a 60-mesh metal filter and put it into a 30cm×50cm tray;

[0031] 2. Baking of the bonded wafer: put the wafer into the tray in the electric oven, the temperature of the electric oven is 190°C, and the baking time is 45 minutes;

[0032] 3. Preheat the fixture frame for bonding wafers and the movable fixture on the fixture frame: the preheating temperature is 50°C;

[0033] 4. Put the configured glue on the heating plate of electric furnace A for heating: Put the prepared adhesive glue on the heating plate of electric furnace A, and the temperature of the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com