Novel silver alloy electrical contact material

A technology of electrical contact materials and alloy materials, applied in contacts, circuits, electrical switches, etc., can solve the problems of unsatisfactory use effect, low hardness, strength, and long service life, and achieve excellent arc extinguishing performance, manufacturing The method is simple and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

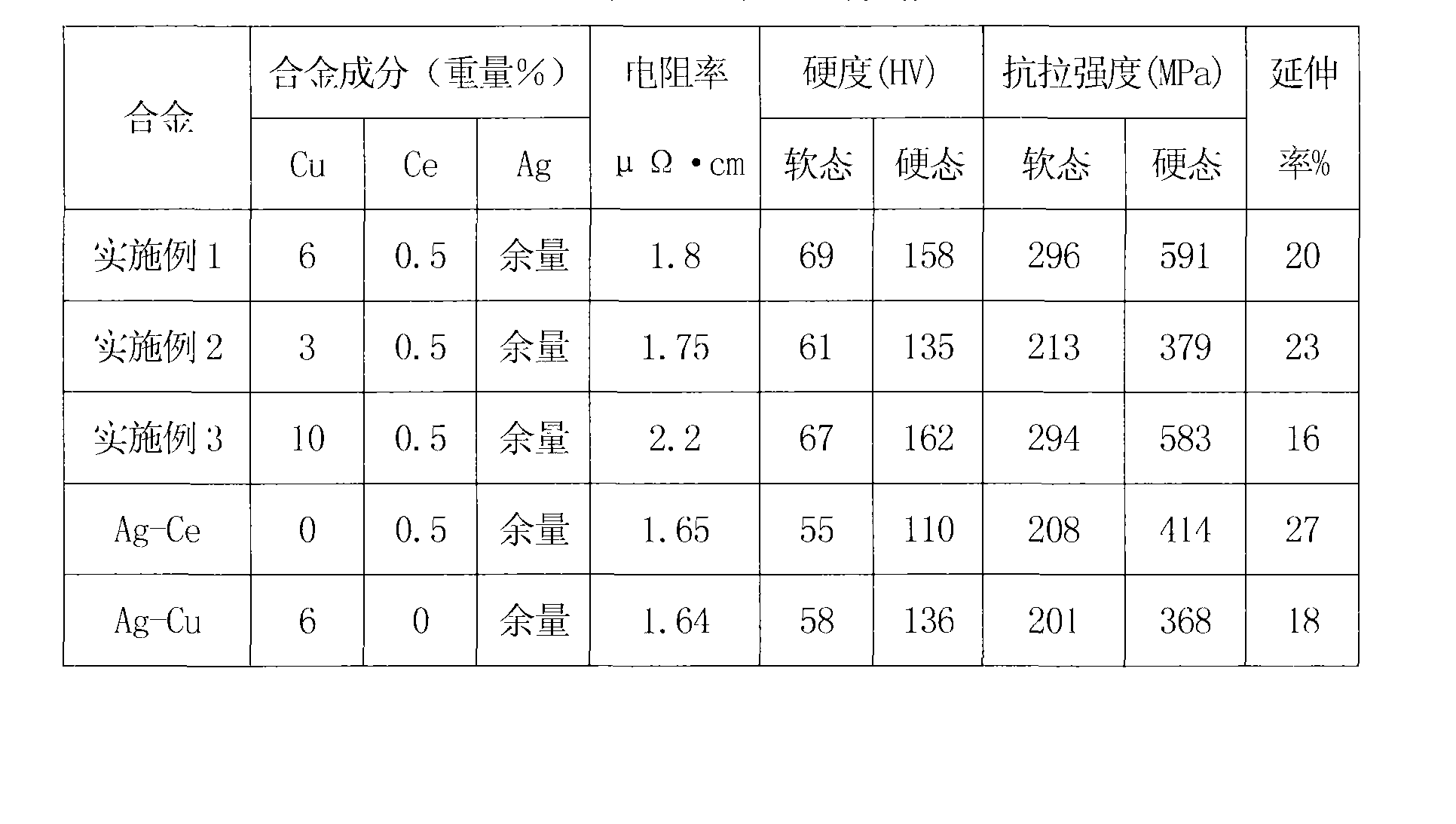

[0012] The alloys of Examples 1-3 of the present invention were prepared according to the composition shown in Table 1.

[0013] 1. The raw materials with the purity of Ag≥99.99%, Ce≥99.95%, and Cu≥99.99% are mixed according to the composition ratio. First, put Ag and Cu into the intermediate frequency furnace for melting to alloy them. After degassing, add Ce and melt for a while Cast into ingots after the alloy composition is uniform;

[0014] 2. In order to eliminate ingot segregation, the alloy needs to be kept at 600°C for 3 hours to make it homogeneous;

[0015] 3. The forming processing method is: hot rolling or hot forging→surface treatment→intermediate rolling→600℃ / 0.5h intermediate annealing (vacuum)→finish rolling or fine drawing into sheet or filament products to the specifications required by the manufacturer.

[0016] Table 1 Properties of silver alloys

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com