Interface shearing strength test method for adhesive bonding sample of sealant and substrate

A technology of shear strength and testing method, which is applied in the direction of applying stable shear force to test material strength, measuring devices, and analyzing materials, which can solve problems such as economic loss, bad social impact, and impact on project quality, and achieve simple operation , Easy to promote, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

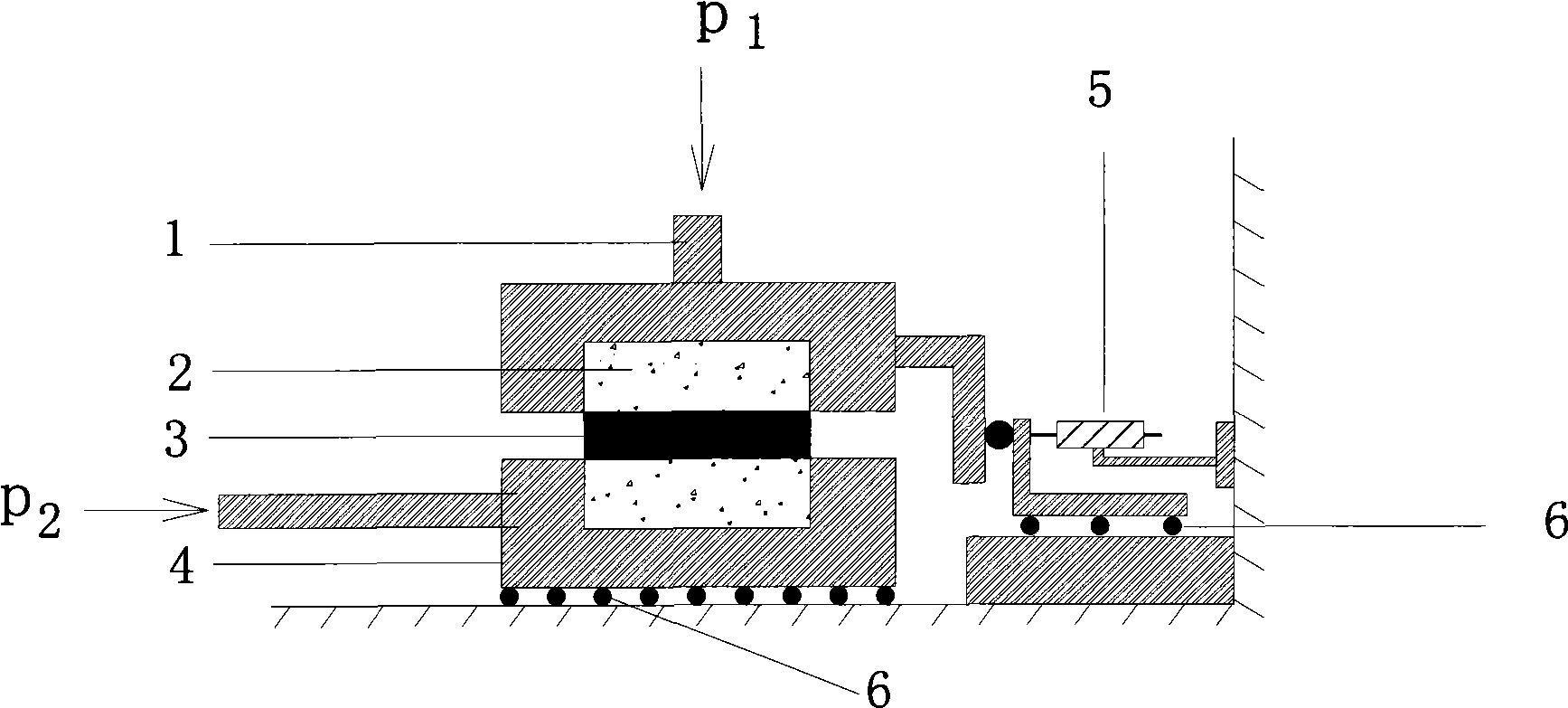

[0012] see figure 1 , according to the technical scheme of the present invention, first make two circular samples of the substrate 2 (concrete) to be adhered, reserve a certain size of the gap shown in Figure 3 in the middle, and pour the sealant into it to make The adhered substrate 2 and the sealant 3 become a whole bonding sample, which is placed in an environment with a temperature of 20±2°C and a relative humidity of 65±5% for 28 days;

[0013] The adhered substrates 2 of the bonded samples are placed in the upper shear box 1 and the lower shear box 4, respectively, and the sealant 3 is exposed, wherein a dynamometer 5 is connected to one side of the upper shear box 1, and the The bottom of the dynamometer 5 is provided with a pulley 6; the lower part of the lower shear box 4 is also provided with a pulley 6;

[0014] During the test, a positive pressure P is applied to the upper part of the upper shear box 1 1 , in which the horizontal force P can be guaranteed 2 All ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com