Gear box detection device

A gearbox detection and gearbox technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems that affect the performance of the gearbox and the difficulty in obtaining detection parameters, etc., and achieve the effects of reducing energy consumption, good performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0039] It should be noted that: first, in the present invention, unless otherwise specified, the radial direction is the radial direction relative to the transmission shaft of the gearbox; second, the detection frame is not limited to a whole, and may include relative Multiple sections that are independent and fixed to the work environment.

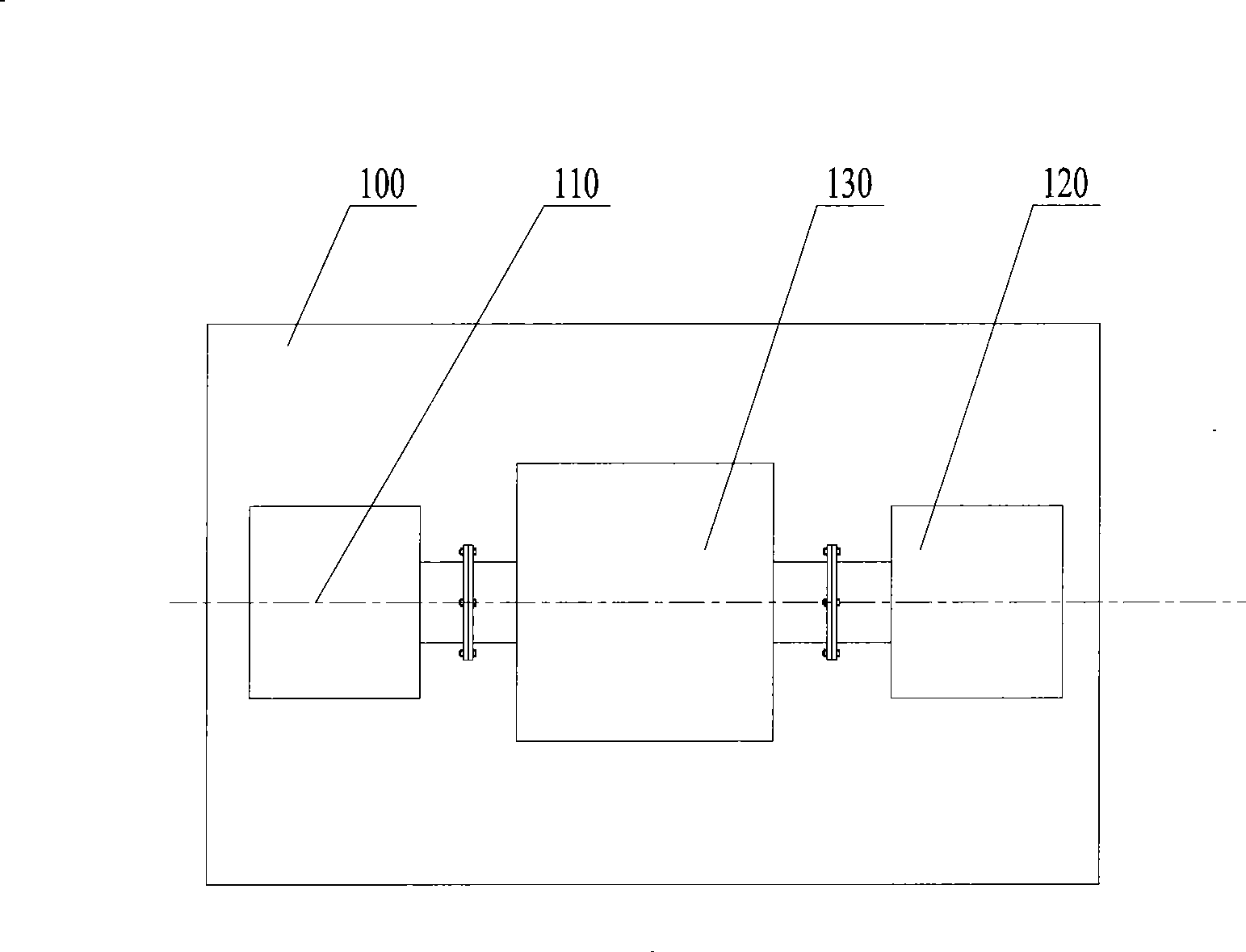

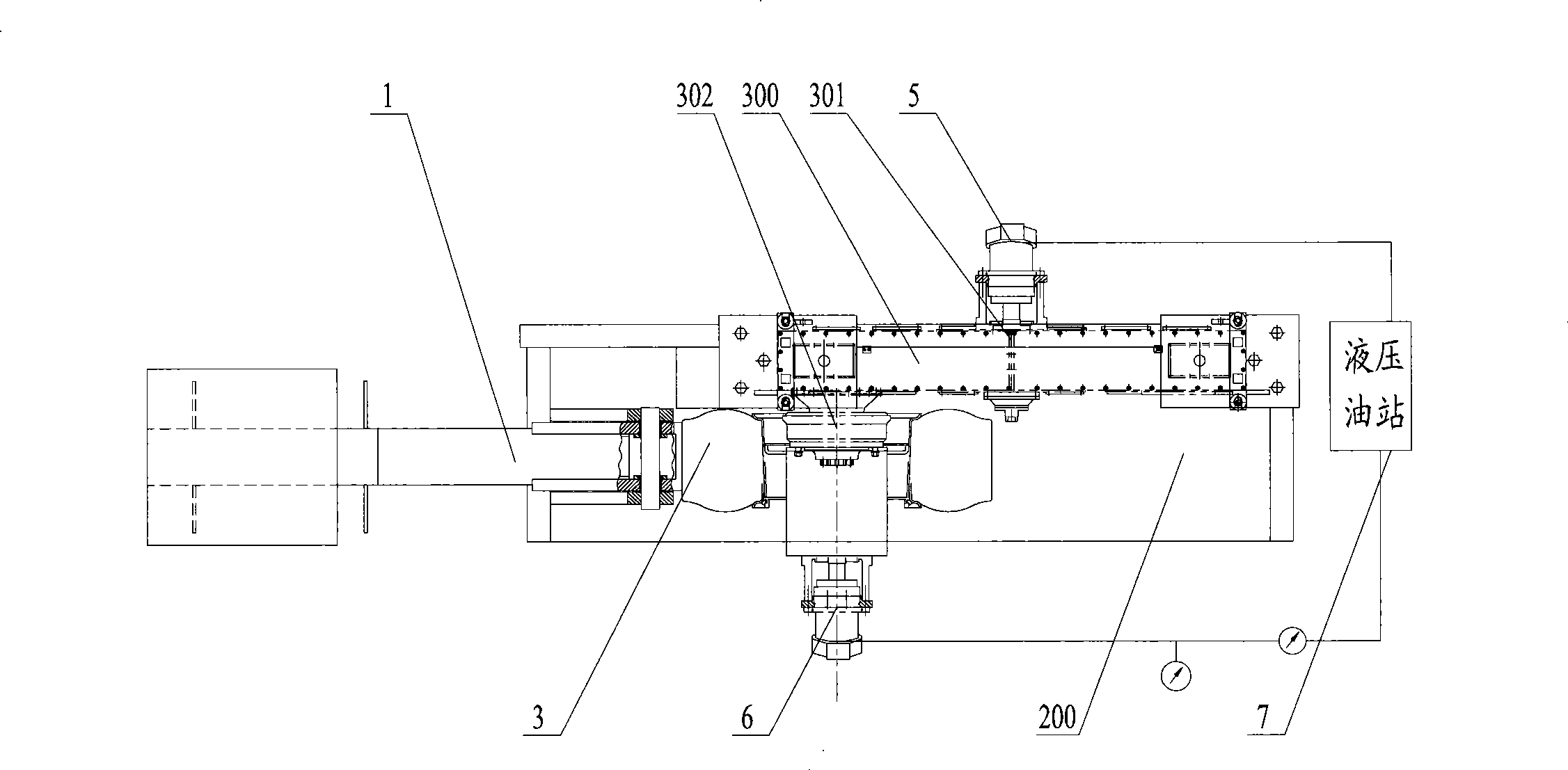

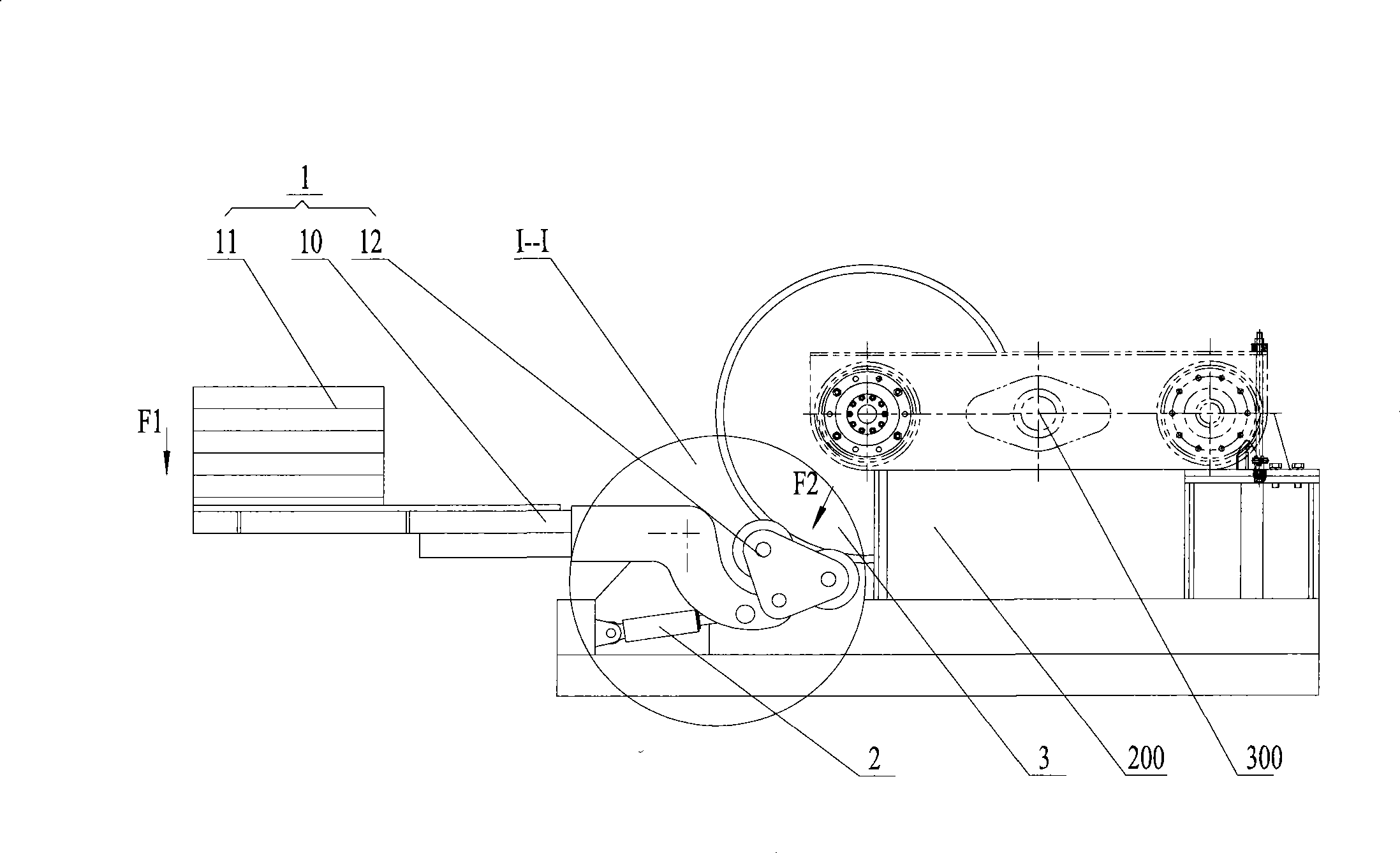

[0040] refer to figure 2 , figure 2It is a structural schematic diagram of the transmission detection device provided in the first embodiment of the present invention in a top view direction. The transmission detection device provided in this embodiment includes a detection frame 200 , a hydraulic motor 5 , a variable hydraulic pump 6 , a radial load applying mechanism 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com