Separated environment friendly toilet for immediate processing

A separate and rapid technology, applied in the direction of flushing toilets, sanitary equipment for toilets, flushing equipment with water tanks, etc., can solve problems such as failure to use normally, waste of organic fertilizer resources, long processing time, etc., and achieve reasonable design , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

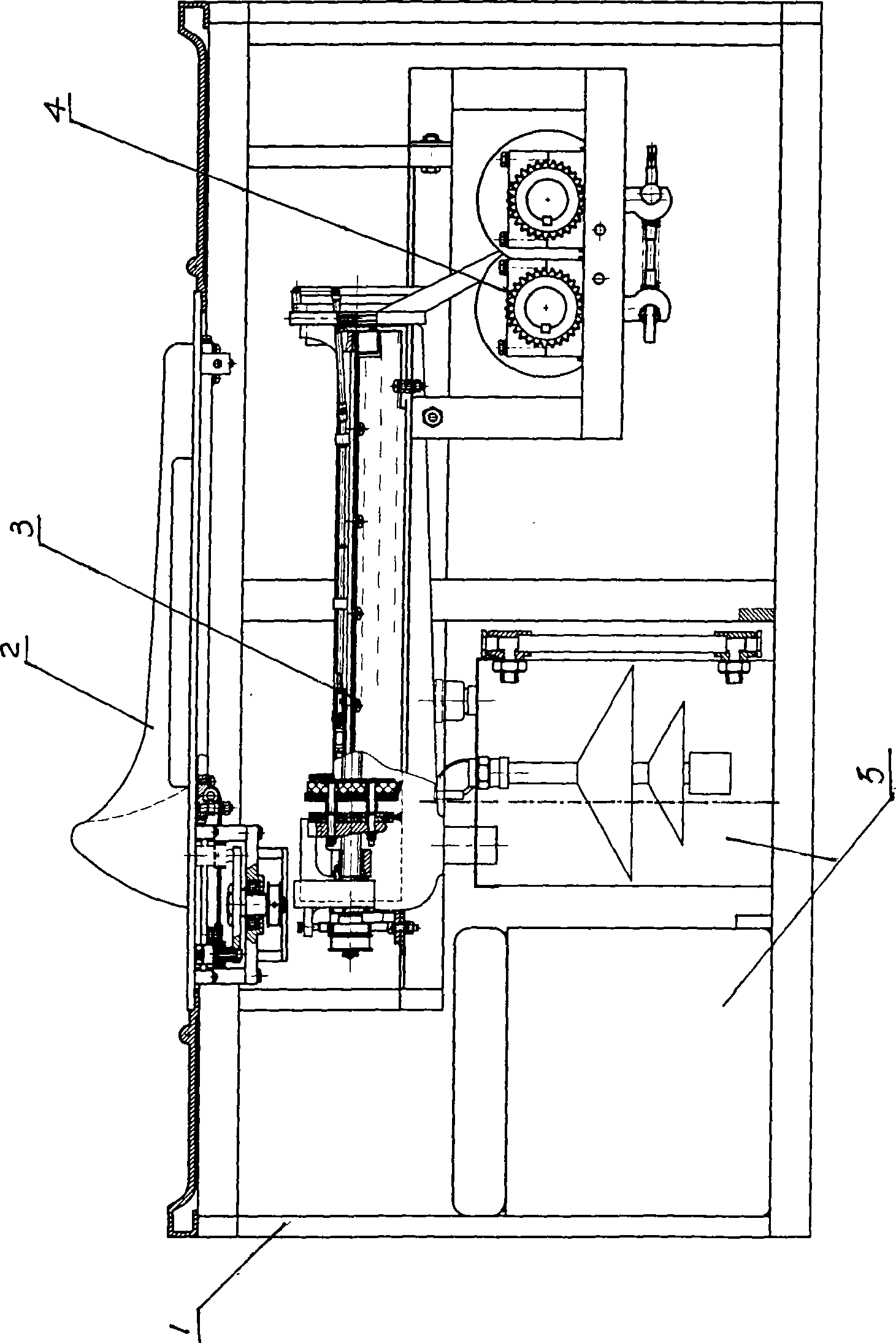

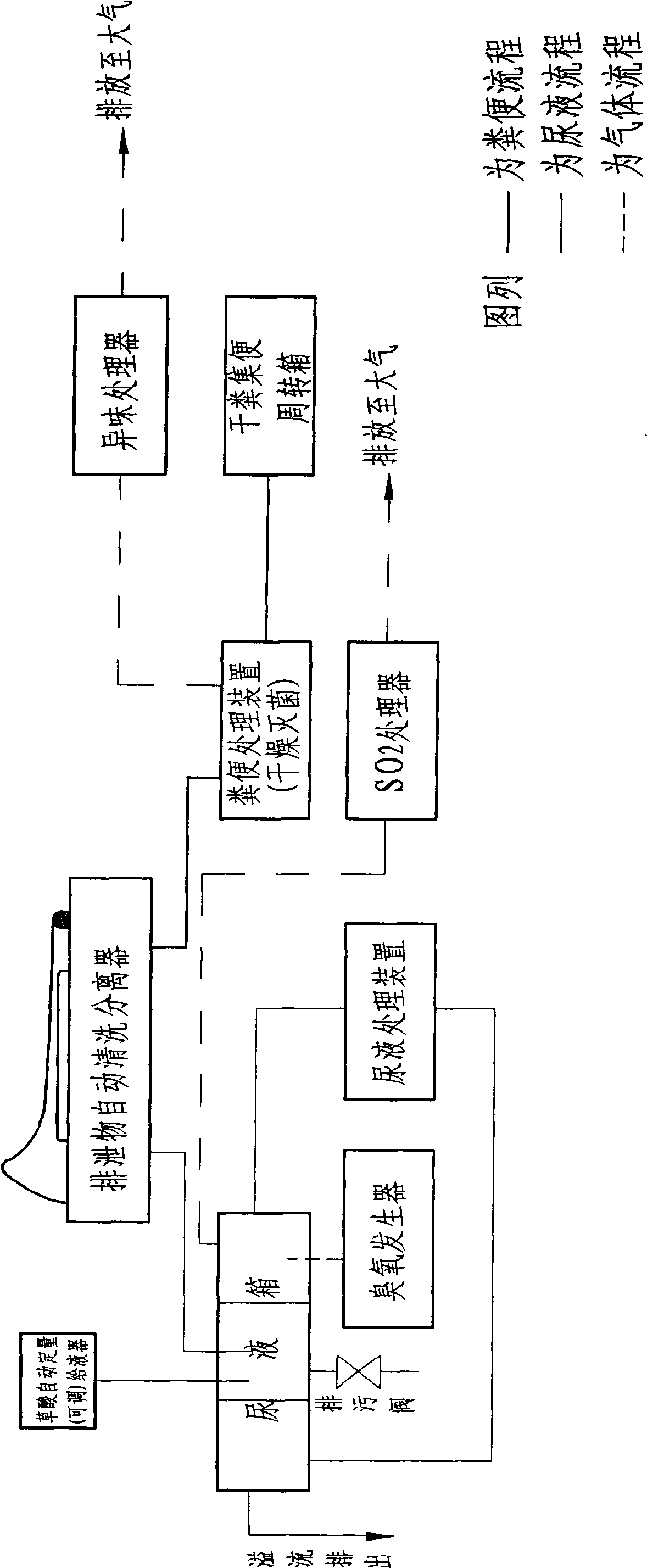

[0041] Refer to attached Figure 1-14 , The structure of the separated fast-processing environment-friendly toilet is composed of a box frame 1, an automatic door opening device 2, an excrement automatic cleaning separator 3, a urine processing device 5 and a feces processing device 4. The automatic door-opening device 2 is mounted on the upper part of the box frame 1, the excrement automatic cleaning separator 3 is mounted on the assembly frame of the lower part of the automatic door-opening device 2, and the urine processing device 5 and the feces processing device 4 are respectively installed on the lower part of the box frame 1. assembly rack.

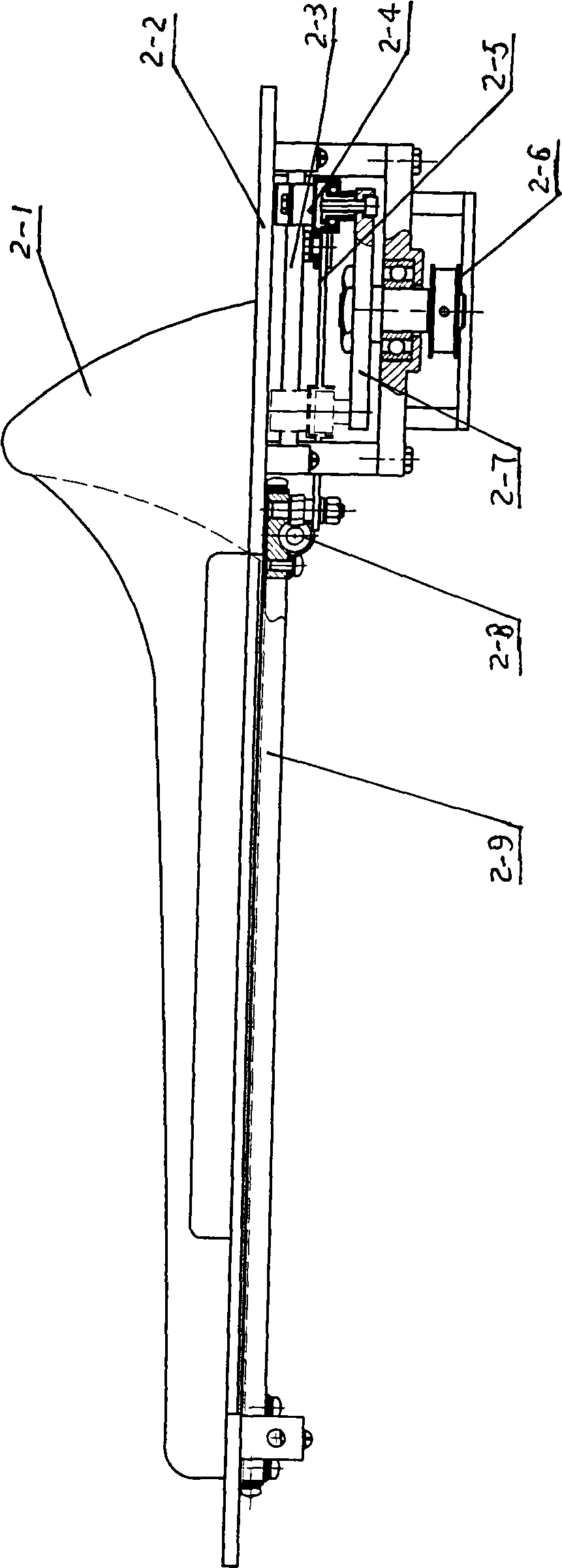

[0042] Automatic door opener 2 comprises toilet or squatting pan 2-1, toilet seat 2-2, swing door 2-9, door opening motor 2-10, guide wheel 2-7, synchronous pulley 2-6, 2-11, synchronous Belt 2-12, sliding rod, push rod 2-4 and connecting rod 2-5. The slide bar has a longitudinal slide bar 2-3 and a transverse slide bar 2-8. Toi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com