Whole-digit inversion type consumable electrode pulse gas-shielded welder

A technology of pulsed gas and melting electrode, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of unable to meet the needs of high-end or special users, monotonous output characteristics, poor reliability, etc., to facilitate production debugging and after-sales Maintenance, consistency and stability improvement, and the effect of meeting usage needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

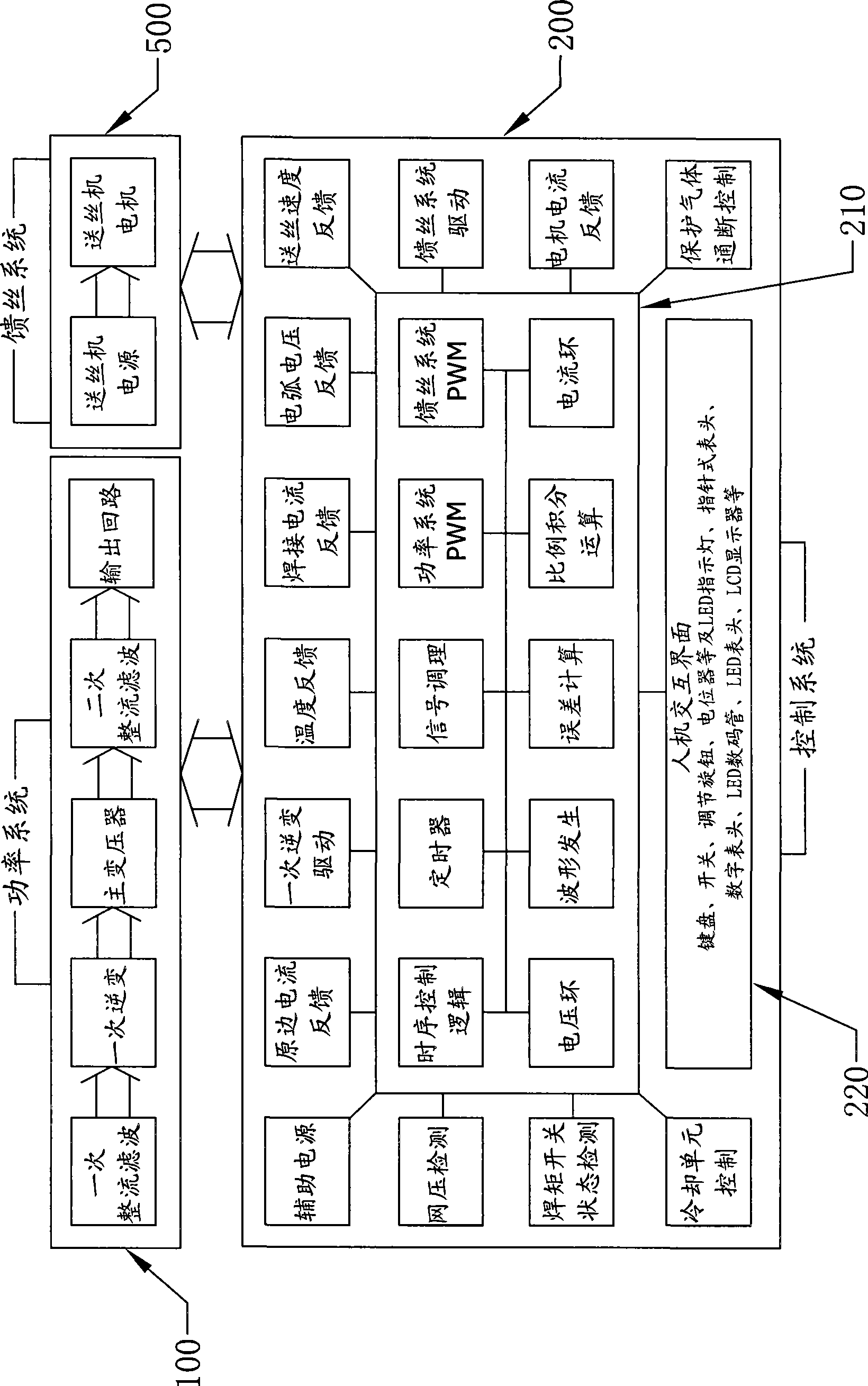

[0033] Such as Figure 4 As shown, the full digital inverter melting pole pulse gas shielded welding machine of the present invention includes:

[0034] The power system 300 has primary rectification and filtering, primary inverter, main transformer, secondary rectification and filtering, secondary inverter, output circuit, and

[0035] The wire feeding system 600 has a wire feeder power supply and a wire feeder motor,

[0036] In response to a control signal, the power system 300 and the wire feeding system 600 operate in coordination to convert the high-voltage positive-rotating alternating current of the grid into low-voltage pulsating direct current, and complete the conversion of electric energy into thermal energy through the welding circuit; and

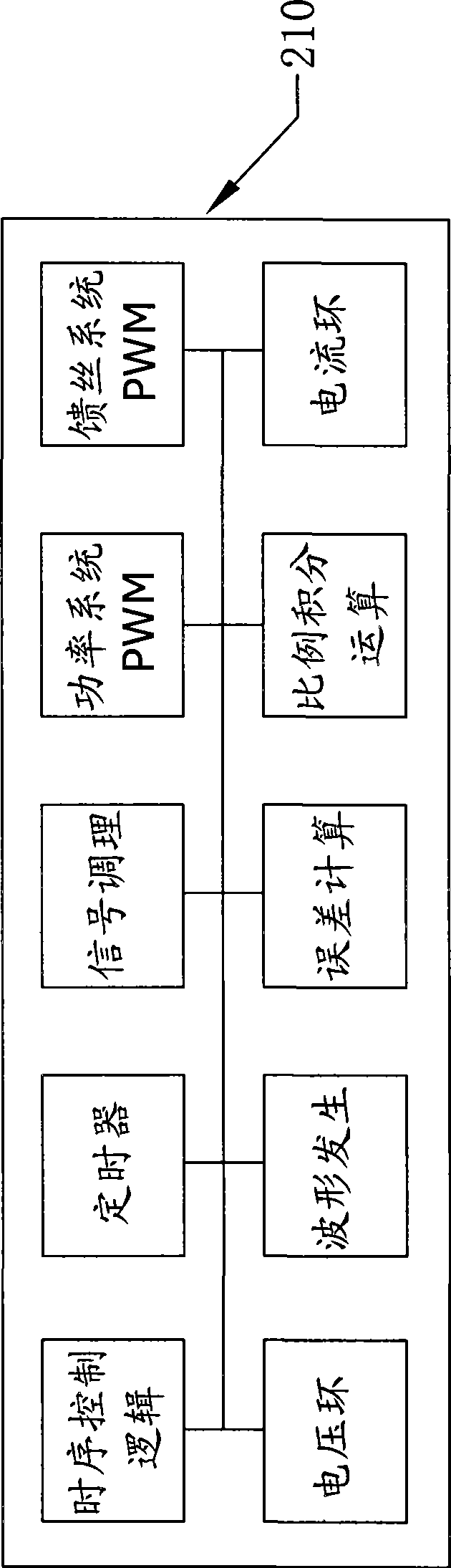

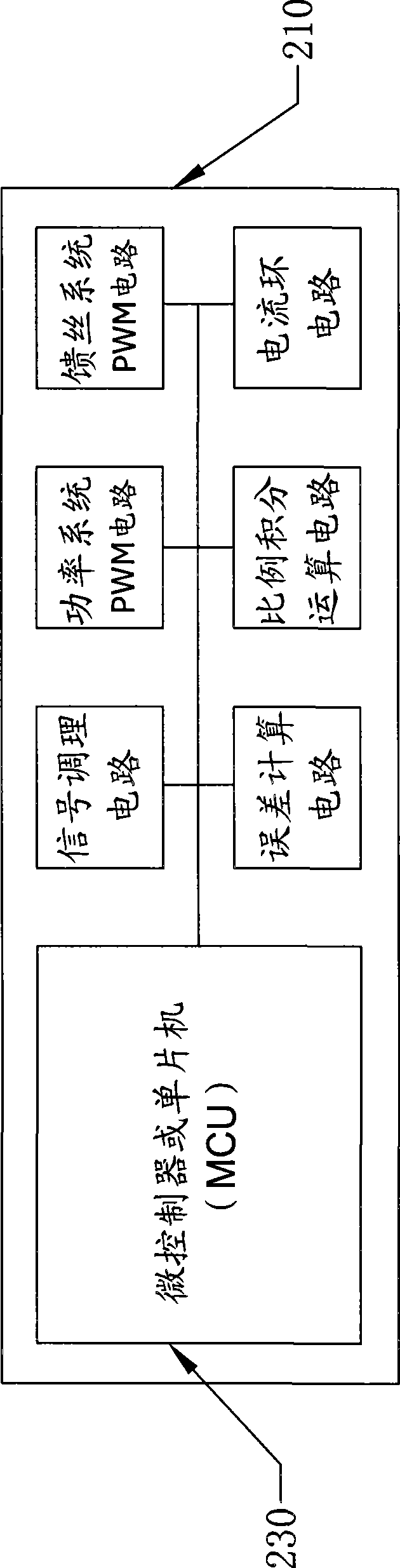

[0037] The control system 400 has auxiliary power supply, grid voltage detection, primary side current feedback, welding current feedback, arc voltage feedback, power unit temperature feedback, wire feeding speed feedback, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com