A self-cleaning enhanced heat transfer device inside a tube

A technology for enhancing heat transfer and self-cleaning, applied in the direction of cleaning heat transfer devices, heat transfer modification, cleaning of rotating equipment, etc., can solve the problems of mutual wear of rotating parts, inconvenient on-site installation, lack of power, etc., and reduce mutual friction. , The effect of improving the service life and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

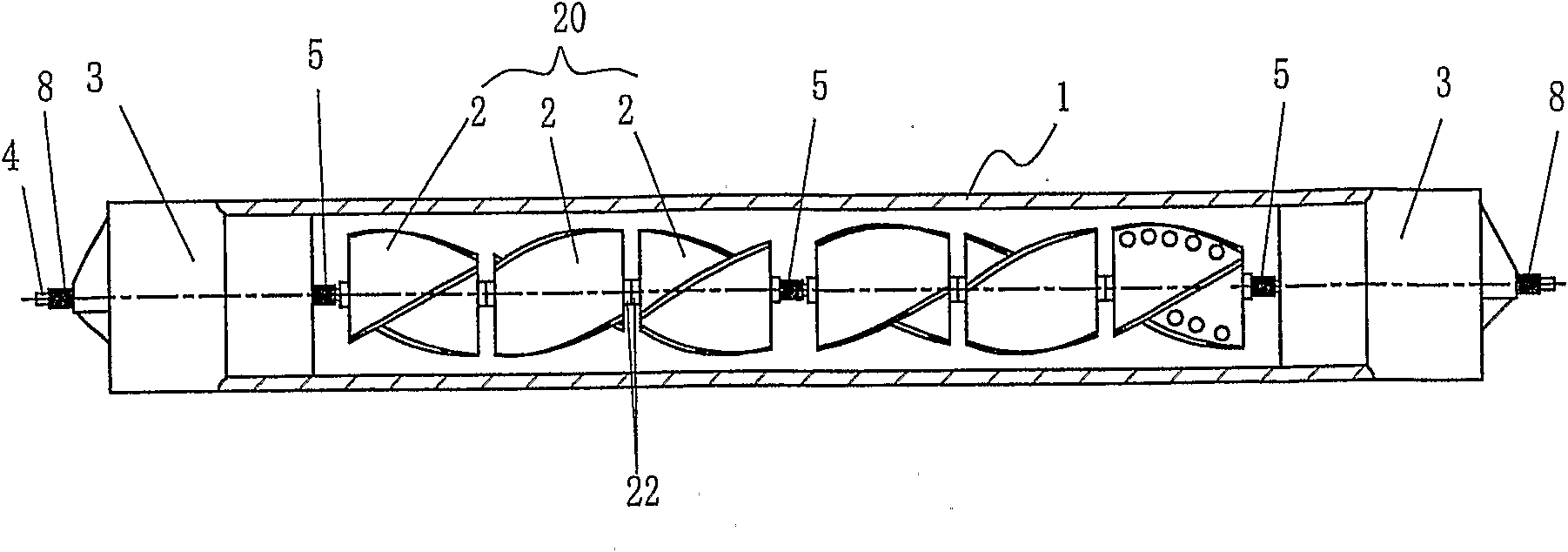

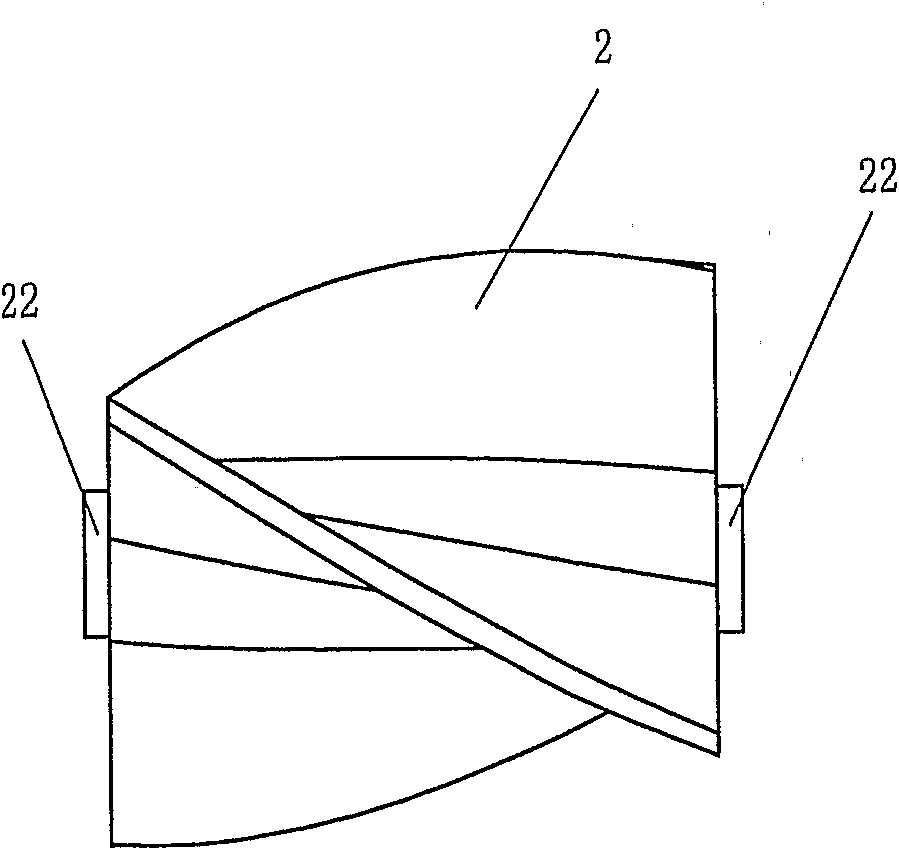

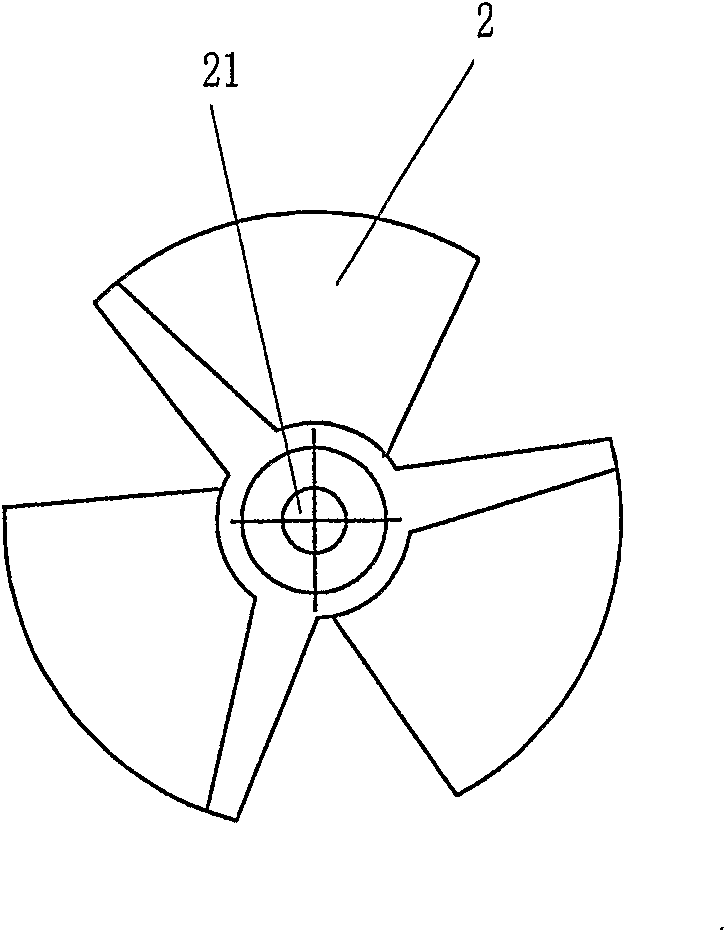

[0038] Such as Figure 1-12 As shown, the self-cleaning in-tube self-cleaning enhanced heat transfer device of the present invention includes a plurality of rotating parts 2 arranged in the heat transfer tube 1, and a fixing frame 3 is provided at both ends of the heat transfer tube 1 through a socket connection. The support shaft 4 passing through the heat transfer tube 1 is fixedly supported on the frame 3, and the plurality of rotating parts 2 have a central hole 21 for the support shaft to pass through, and the diameter of the central hole 21 is slightly larger than the axis of the support shaft 4 diameter, so that the plurality of rotating parts 2 are rotatably supported on the support shaft 4, and at least between a pair of adjacent rotating parts 2, there is a limit separating the adjacent ends of the pair of rotating parts 2. Positioning member 5 , which is fixed on the support shaft 4 , and the limiting member 5 divides the plurality of rotating parts 2 into two or mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com