Differential pressure emission type multi-diameter separating Hopkinson pulling and pressing integrated rod

A multi-diameter, separate technology, applied in the direction of measuring devices, impact testing, machine/structural component testing, etc., can solve the problems of non-uniform positioning of poles and launching guns, invariable volume, troublesome operation, etc., to achieve rapid large-scale Wide range of mechanical action, unified and simple installation work, and reduced space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

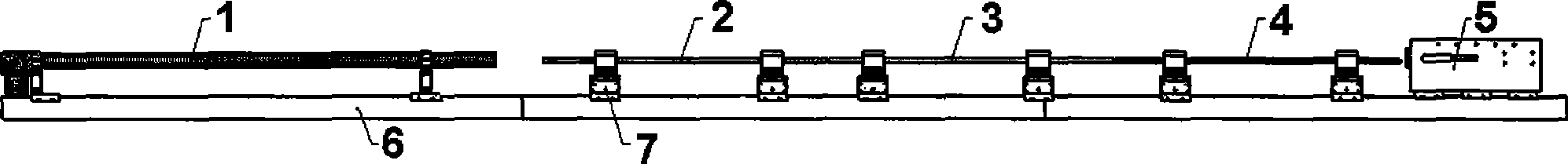

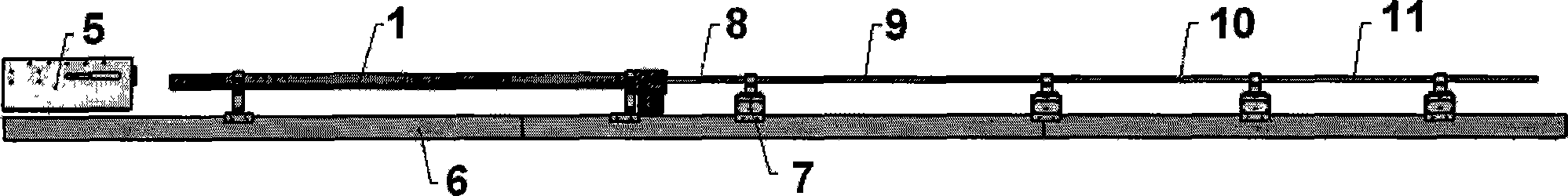

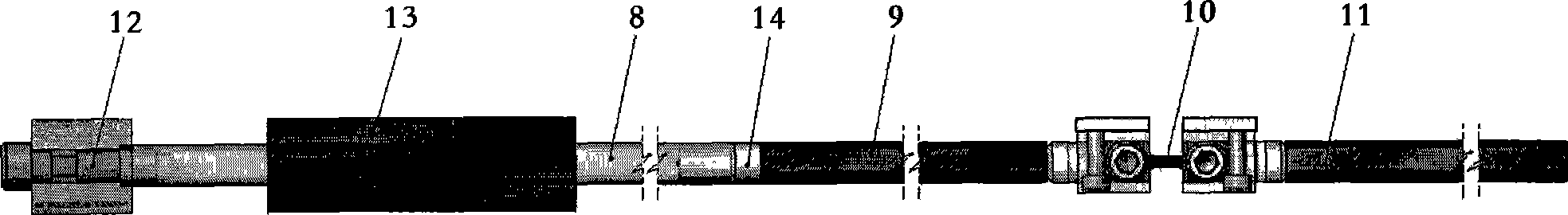

[0019] Referring to Figure 1(a), Figure 1(b), and Figure 1(c), this embodiment includes a launch system 1, an incident pressure rod 2, a transmission pressure rod 3, a pull rod 8, an incident pull rod 9, a transmission pull rod 11, and an absorption rod 4. Hydraulic buffer 5, precision fine-tuning support 7, shaping bolt 12 and optical guide rail 6, the optical guide rail 6 is the base of the equipment, and is also a benchmark for unified positioning; launch system 1, hydraulic buffer 5, precision fine-tuning support 7 is installed on the optical guide rail 6, and the incident pressure rod 2, the transmission pressure rod 3, the pull rod 8, the incident pull rod 9, the transmission pull rod 11, and the absorption rod 4 are installed on the precision fine-tuning support 7; in the pressure rod system, the launch system 1 is installed On one side of the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com