Manufacturing method of double-thread fastener

A technology of double-thread thread and manufacturing method, which is applied to threaded fasteners, manufacturing tools, screws, etc., can solve the problems of high loss cost of assembly and disassembly tools, low assembly and disassembly efficiency, and easy failure, and shorten assembly and disassembly time. , Improve work efficiency and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing of description:

[0039] The invention improves the common standard threaded fastener into a double threaded thread structure. This embodiment is described in detail with the double thread structure of the bolt 1 and the nut 2 .

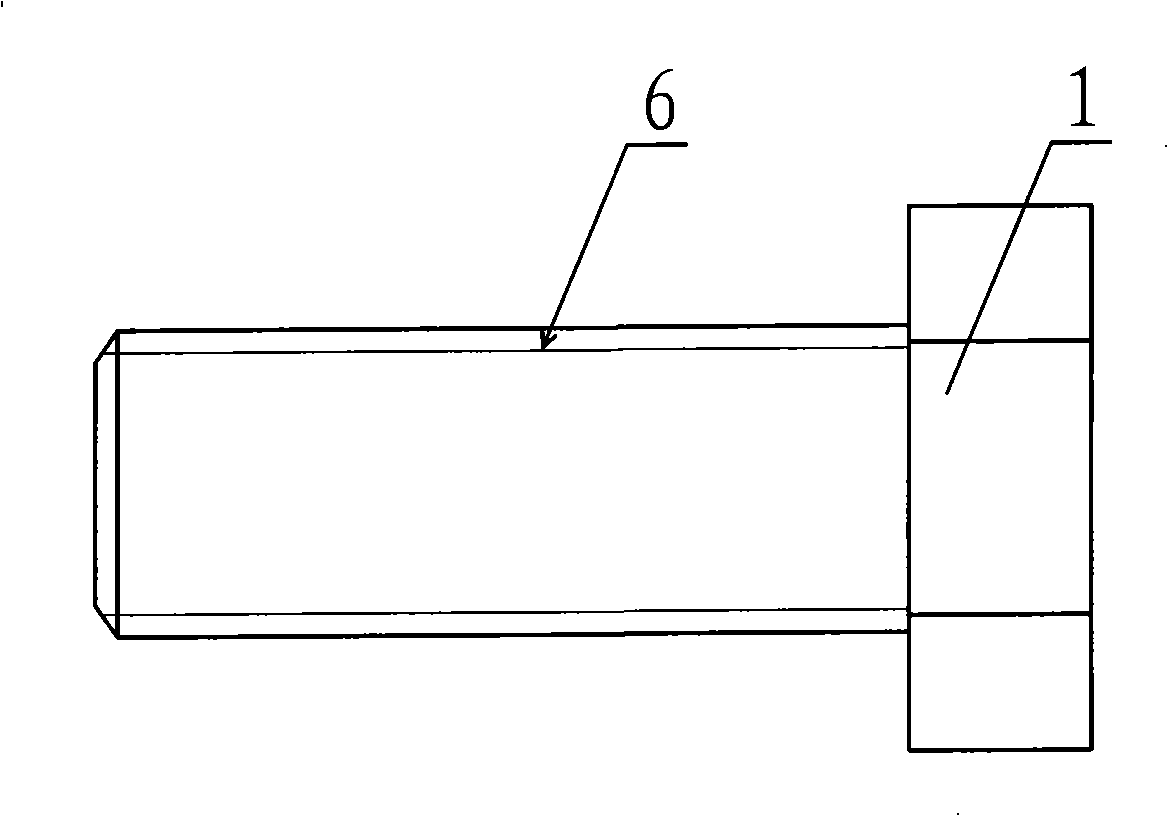

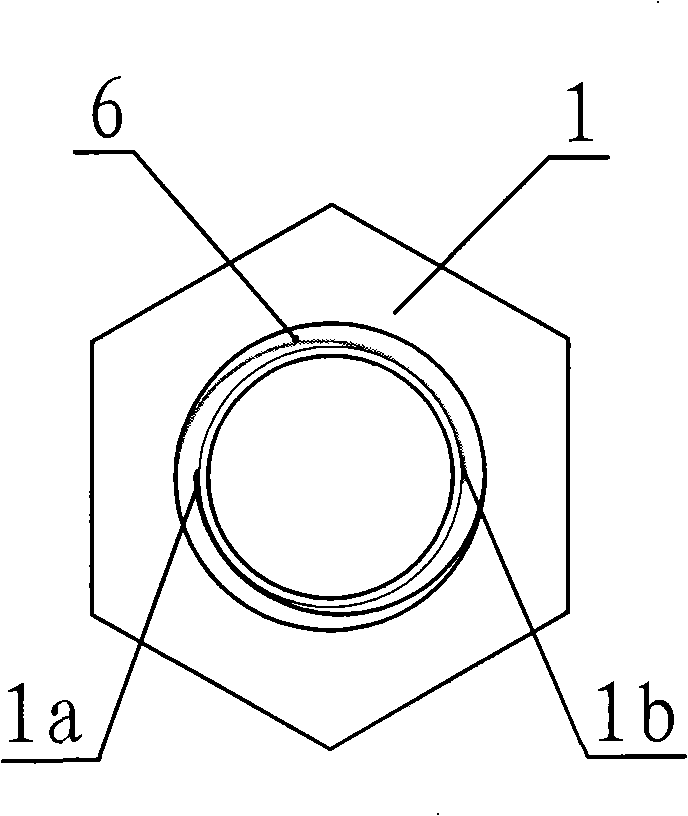

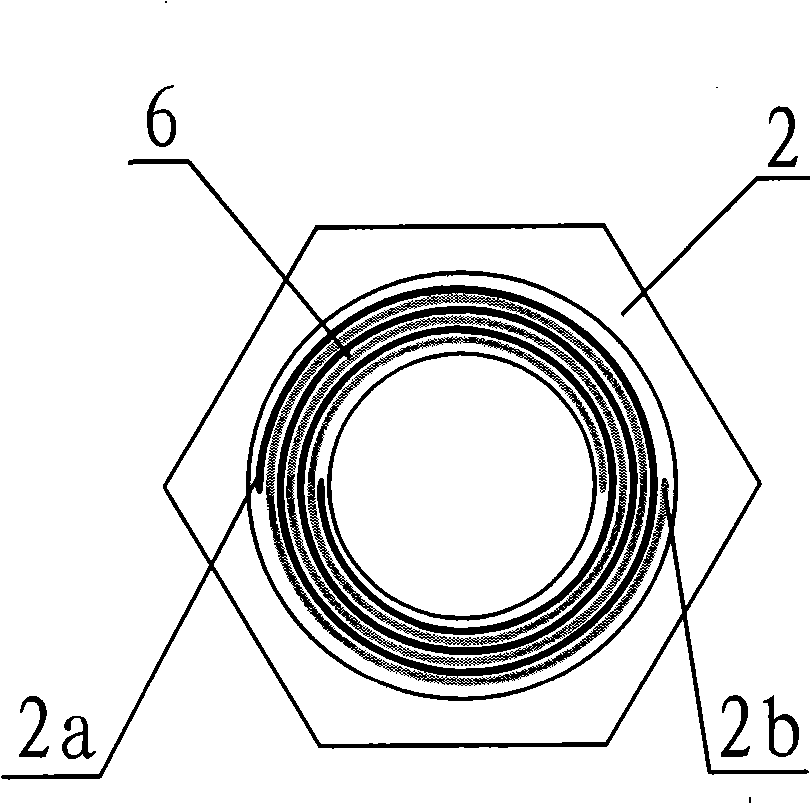

[0040] Such as figure 1 , figure 2 , image 3 As shown, the bolt 1 and the nut 2 of the present invention include a fastener body with a threaded portion 6, the threaded portion 6 has a double thread structure, the threaded portion 6 of the bolt 1 is composed of double threads 1a, 1b, and the nut 2 The threaded portion 6 is composed of double threads 2a, 2b, the two threads are evenly distributed alternately, and the thread diameter and pitch are the same, and the start and end ends of the two threads are located on the same cross section.

[0041] In the present invention, the threaded portion 6 has a thread diameter of M2-M20 and a thread pitc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com