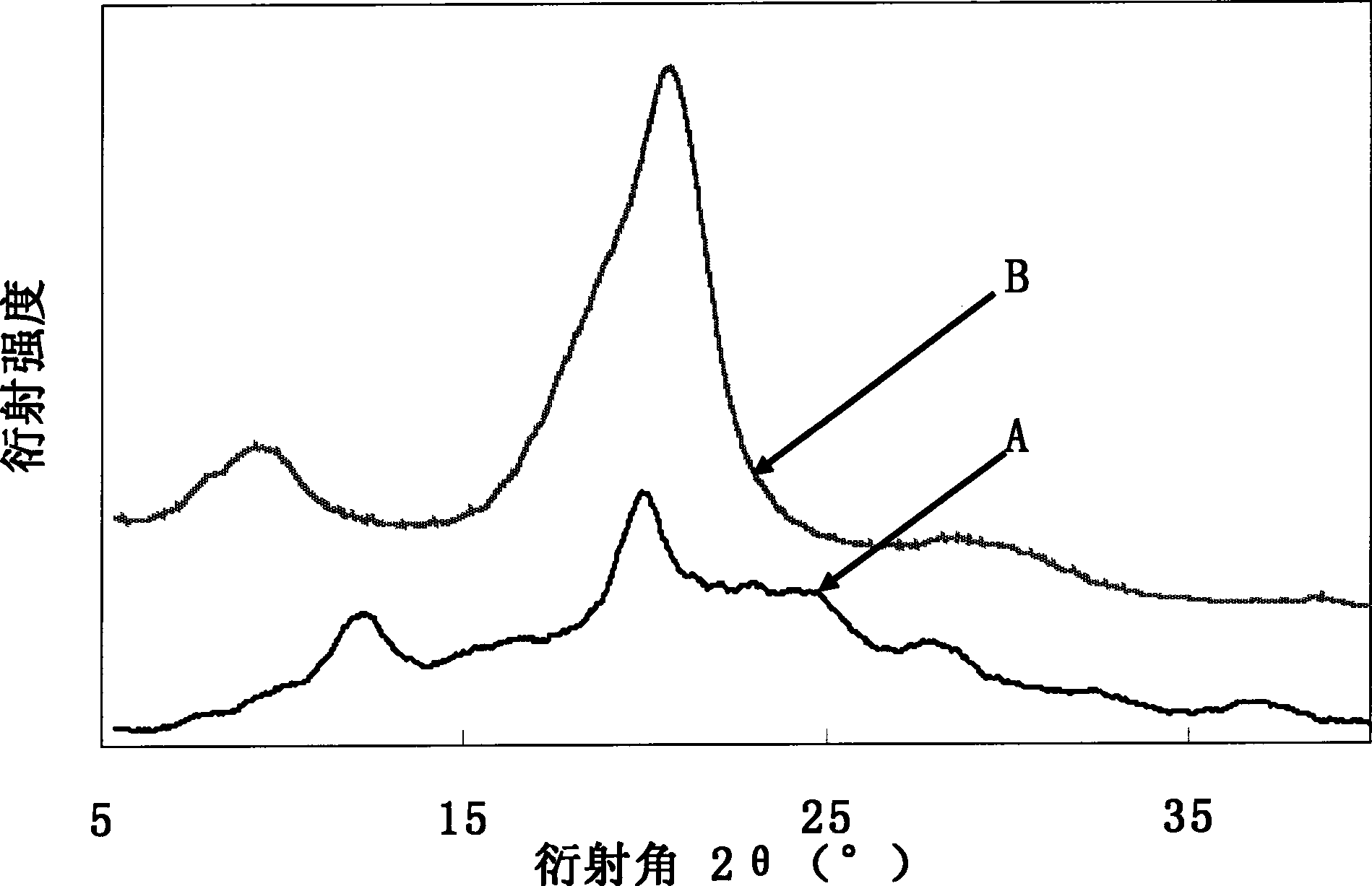

Silk fibroin porous three-dimensional material and preparation method thereof

A silk fibroin, three-dimensional technology, applied in medical science, prosthesis, etc., can solve the problem of small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

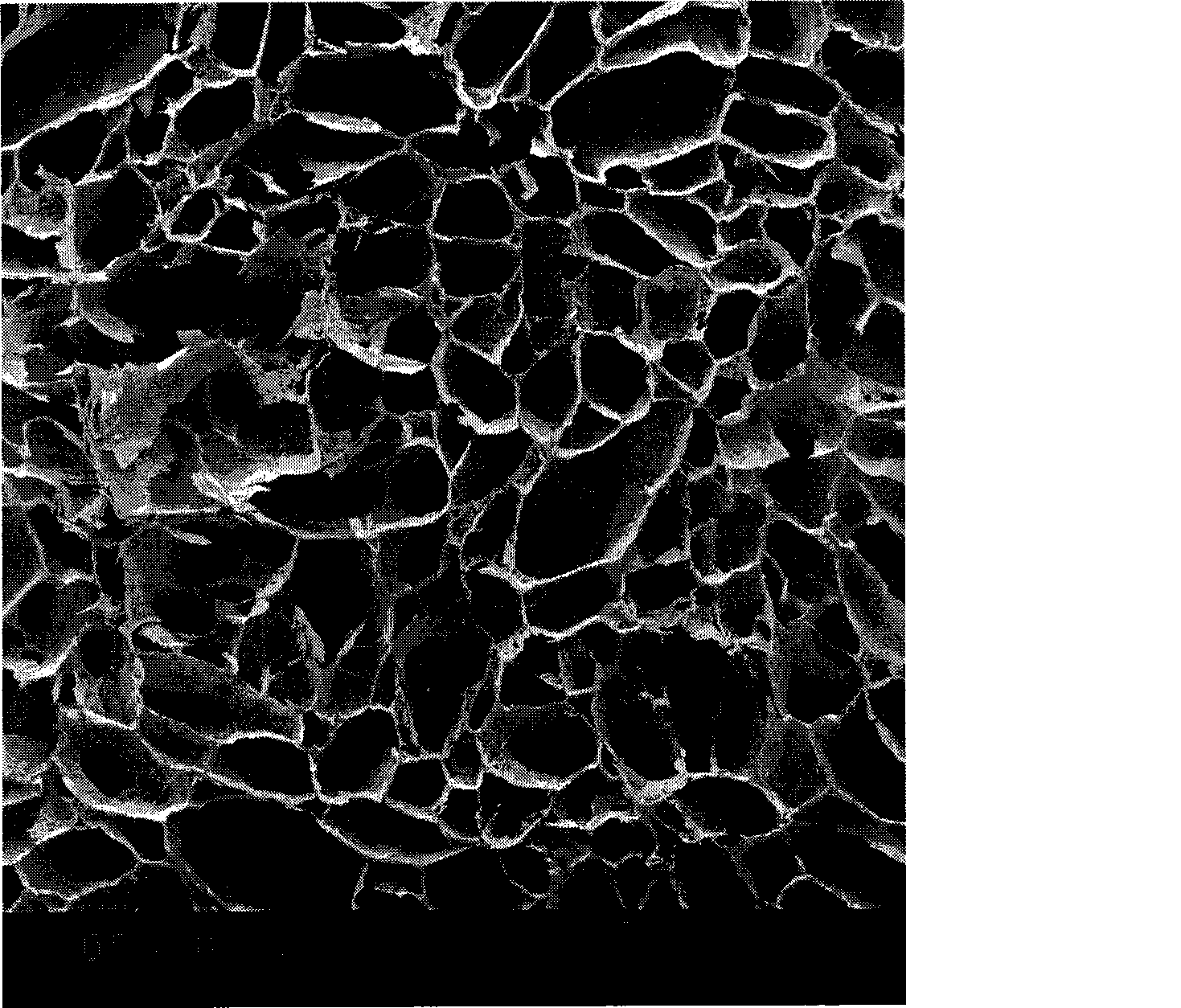

Embodiment 1

[0022] The preparation steps of the silk fibroin porous three-dimensional material provided in this embodiment are as follows:

[0023] 1. Put 1 kg of cocoon shells into 50 liters of neutral soap solution with a mass concentration of 0.5%, and treat them at 98-100°C for 2 hours to degumming the cocoon shells, and obtain pure silk fibroin (silk fibroin) after fully washing . The dried pure silk fibroin is dissolved in 5 liters of 9.3 mol / liter lithium bromide aqueous solution with stirring at 65±2° C. to form a silk fibroin mixed solution.

[0024] 2. Using a cellulose membrane as a dialysis material, dialyzing the obtained silk fibroin mixed solution with deionized water to remove impurities such as lithium bromide to obtain a pure silk fibroin solution.

[0025] 3. Adjust the mass concentration of the silk fibroin solution to 5%.

[0026] 4. Pour the silk fibroin solution into a stainless steel box, and quickly freeze at -30°C for 5 hours to obtain a silk fibroin solution f...

Embodiment 2

[0033] Put 1 kg of raw silk into 30 liters of sodium carbonate aqueous solution with a mass concentration of 0.2%, treat it at 98-100°C for 2 hours, degumming the raw silk, and obtain pure silk fibroin (ie silk fibroin) after fully washing. The dried pure silk fibroin is heated and dissolved at 75±5°C with 8 liters of calcium chloride, water and ethanol solution with a molar ratio of 1:8:2 to obtain a silk fibroin mixed solution.

[0034] The cellulose membrane is used as a dialysis material, and the obtained silk fibroin mixed solution is dialyzed with deionized water to remove impurities such as calcium chloride to obtain a pure silk fibroin solution.

[0035] Adjust the mass concentration of silk fibroin solution to 2%.

[0036] The silk fibroin solution was poured into an aluminum box, and quickly frozen at -60°C for 20 hours to obtain a silk fibroin solution frozen body.

[0037] Store the frozen body in a refrigerator at -10°C, and freeze and crystallize for 60 days.

[...

Embodiment 3

[0041] Put 100 grams of waste silk into 4 liters of sodium carbonate aqueous solution with a mass concentration of 0.05%, degumming at 98-100° C. for 0.5 hours, repeat the treatment 3 times, and obtain pure silk fibroin (ie silk fibroin) after sufficient washing. The dried pure silk fibroin is dissolved in 50 ml of 9.3 mol / L lithium bromide aqueous solution with stirring at 65±2° C. to form a mixed silk fibroin solution.

[0042] The cellulose membrane is used as a dialysis material, and the obtained silk fibroin mixed solution is dialyzed with deionized water for 3 days to obtain a pure silk fibroin solution.

[0043] Concentrate with 10% polyethylene glycol solution to obtain a silk fibroin solution with a mass concentration of 15%.

[0044] The silk fibroin solution was poured into a stainless steel box, and quickly frozen at -20°C for 10 hours to obtain a silk fibroin solution frozen body.

[0045] Store the frozen body in a refrigerator at -5°C, and freeze and crystalliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com