Non-formaldehyde flame retardant for viscose fiber

A viscose fiber and flame retardant technology, applied in the field of formaldehyde-free flame retardants, can solve the problems of large formaldehyde residues, etc., and achieve the effects of less strength reduction, good hand feeling, and good whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

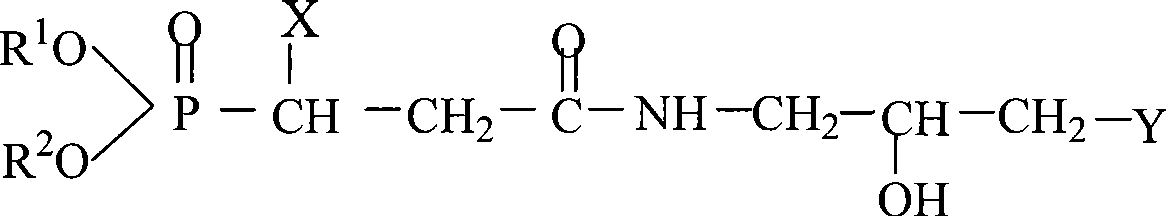

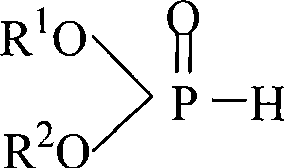

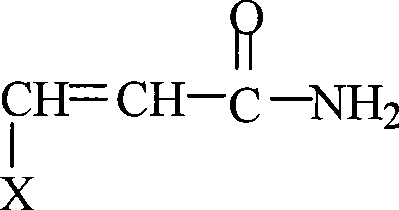

[0028] The specific synthesis process of the present invention is to add phosphite and acrylamide in a molar ratio of 1.02:1, weigh them and add them to the reactor. After the two components are mutually soluble, add halides, oxides, and hydroxides of divalent metals, stir well, and after they are completely dissolved, add the catalyst; when the amount of the catalyst is added to about 50-60%, a violent explosion occurs Exothermic reaction, at this time, the exothermic reaction is controlled by controlling the rate of addition of the catalyst, so that the temperature does not exceed 70°C; drop until the exothermic reaction no longer occurs, keep the reaction for 3 hours after the drop, and the temperature drops to room temperature , to obtain white crystals, namely the crude product of alkoxyphosphorylpropionamide.

[0029] The obtained intermediate crude product was dissolved in distilled water at a ratio of 100ml per mole, heated up to 30°C and added to 20% concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com