Crystal preparation and crystal prepared thereby

A technology of crystal and potassium aluminum sulfate, which is applied in the field of hollow pyramid crystal and its preparation, can solve problems such as inconvenient operation, insufficient ornamental value, and irregular crystal shape, and achieve strong operability, enhanced observation ability, and simple preparation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

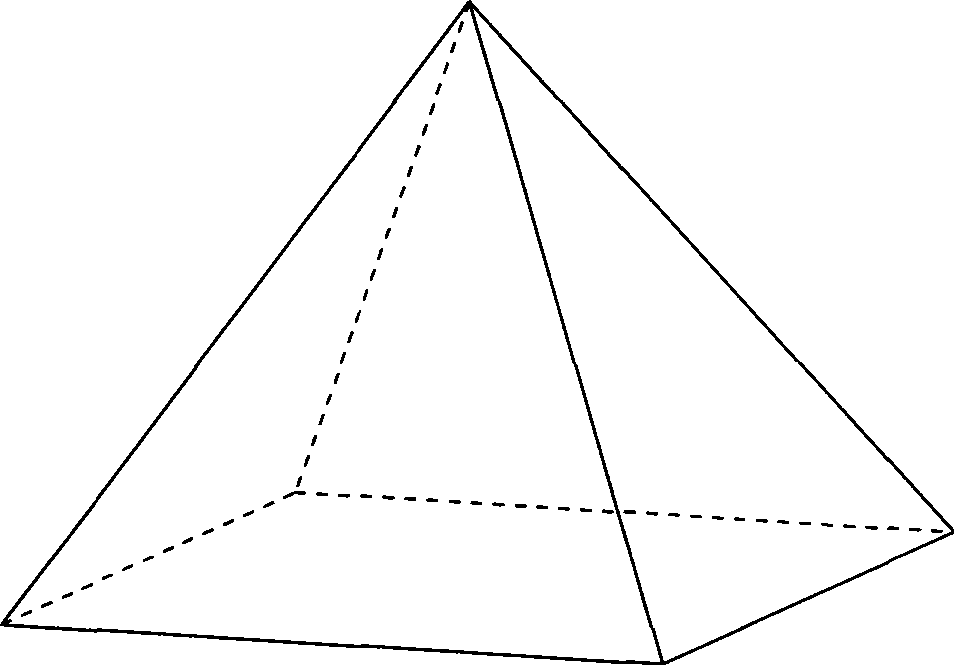

[0021] Specifically, the preparation method of the above-mentioned hollow pyramid crystal of the present invention comprises the following steps:

[0022] Step 1: Prepare a sodium chloride aqueous solution of a predetermined concentration with hot water of a predetermined temperature.

[0023] Step 2: Add a predetermined mass of aluminum potassium sulfate crystals to the hot sodium chloride aqueous solution prepared in step 1, stir and dissolve and then stop stirring.

[0024] Step 3: after above-mentioned system room temperature is left to stand for a predetermined period of time, sodium chloride and potassium aluminum sulfate precipitate crystallization together, and there are inverted hollow pyramid crystals floating on the surface of the liquid (such as Figure 4 shown).

[0025] Wherein, in the above step 1, the predetermined temperature of the hot water used to prepare the sodium chloride aqueous solution is 70-100° C., and the mass percent concentration of the sodium c...

Embodiment 1

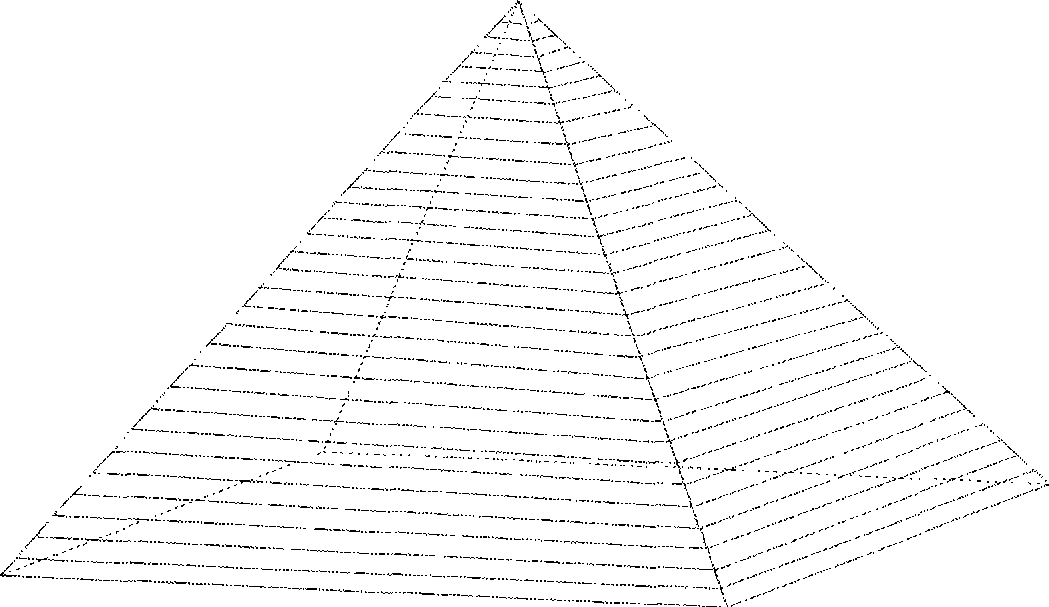

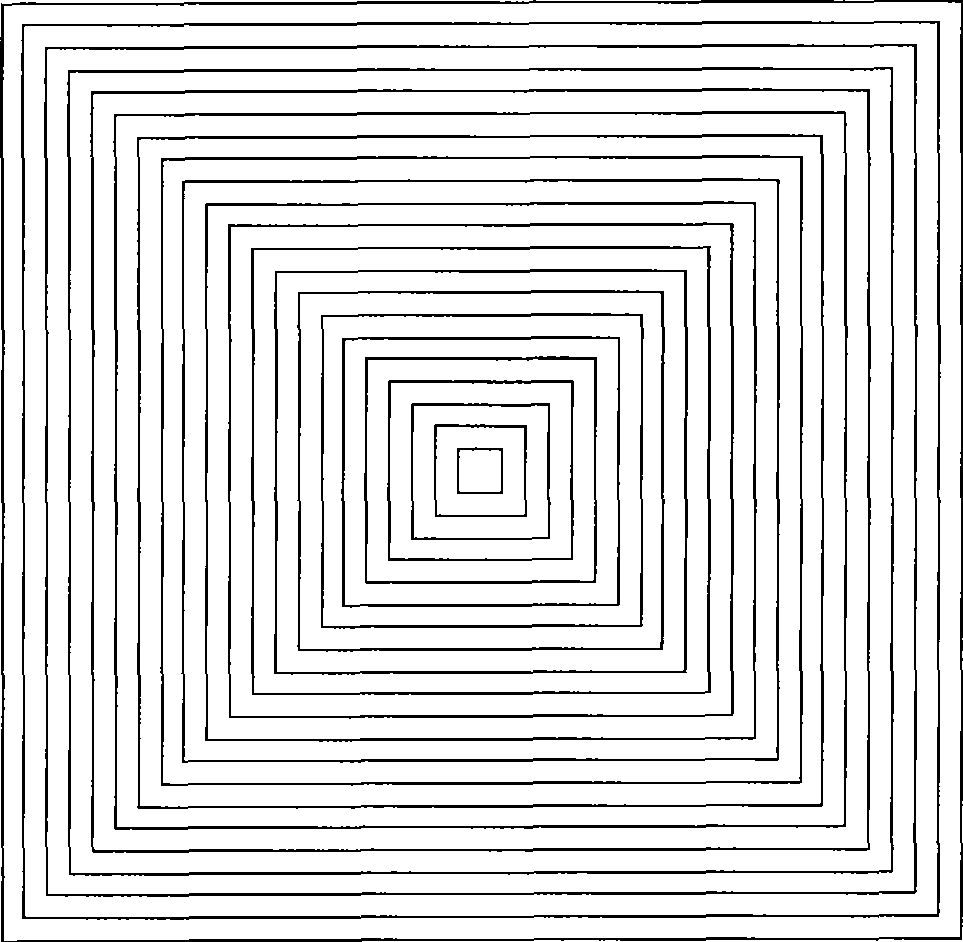

[0033] Add 20g of sodium chloride to 100g of hot water at a temperature of 70°C, stir until it is completely dissolved, then add 10g of aluminum potassium sulfate crystal grains to it, stir until it is completely dissolved, stop stirring, and store at room temperature for 2 days. An upside-down floating hollow pyramid-shaped crystal with an average bottom side length of 1.5cm and an average height of 1.2cm. The inner and outer four surfaces have a stepped undulating structure with an average step height of 0.1cm.

Embodiment 2

[0035] Add 35g of sodium chloride to 100g of hot water at a temperature of 100°C, stir until it is completely dissolved, then add 7g of potassium aluminum sulfate crystal grains to it, stir until it is completely dissolved, stop stirring, and store at room temperature for 2 days. A hollow pyramid-shaped crystal floating upside down. After 7 days, the hollow pyramid-shaped crystal floating upside down grew up. The average length of the bottom side of the crystal is 5.6cm, and the average height is 5.1cm. The inner and outer four surfaces have a stepped undulating structure. The average step height is 0.1 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com