Aeration type photobioreactor and method of use thereof

A photobioreactor and aeration-type technology, which is applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems such as difficulty in popularization, algal wall sticking, and flow dead angle, and achieve low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments. The manufacturing techniques of the present invention are easily implemented by those skilled in the art.

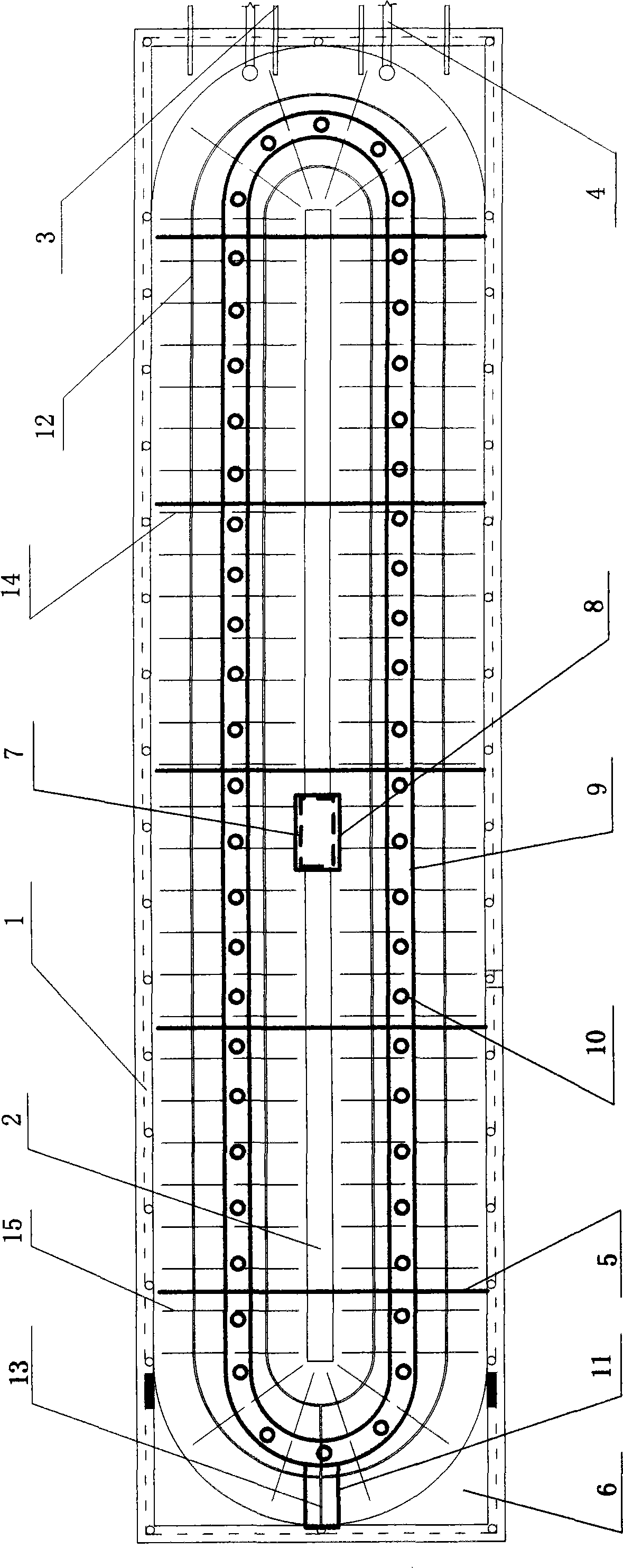

[0021] Such as figure 1, the aerated photobioreactor for cultivating Isoflagellates 3011 is an annular shallow pool 1, the wall is built by bricks, the surface is smoothed with cement, and the bottom of the annular shallow pool 1 is laid with a composite geomembrane. In the pool, a wall 2 with open ends is built with bricks. The width of the pool is 4 meters, the length is 100 meters, the depth is 60 centimeters, and the height of the separation wall 2 is 70 centimeters. A drain pipe 3 is provided at the lower right part of the aerated photobioreactor, and a sewage pipe 4 is provided at the bottom. The top of the aerated photobioreactor is provided with a row of supporting arched flat steel 5, and the two ends of the flat steel are fixed on the upper end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com