Underframe structure of refrigerated container

A technology for refrigerated containers and underframes, which is applied in packaging, transportation and packaging, and transporting passenger cars. It can solve the problems of low welding efficiency, poor formability, and poor impact resistance, so as to improve production efficiency and product quality, and prevent bubbles. The effect of enhanced delamination ability and enhanced impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments with reference to the accompanying drawings, the purpose of which is to facilitate the understanding of the present invention for illustration purposes and not to limit the present invention.

[0024] The idea of the present invention is to improve the structural strength of the underframe of the refrigerated container by improving the underframe structure of the refrigerated container, so that the underframe of the refrigerated container is easy to process and manufacture.

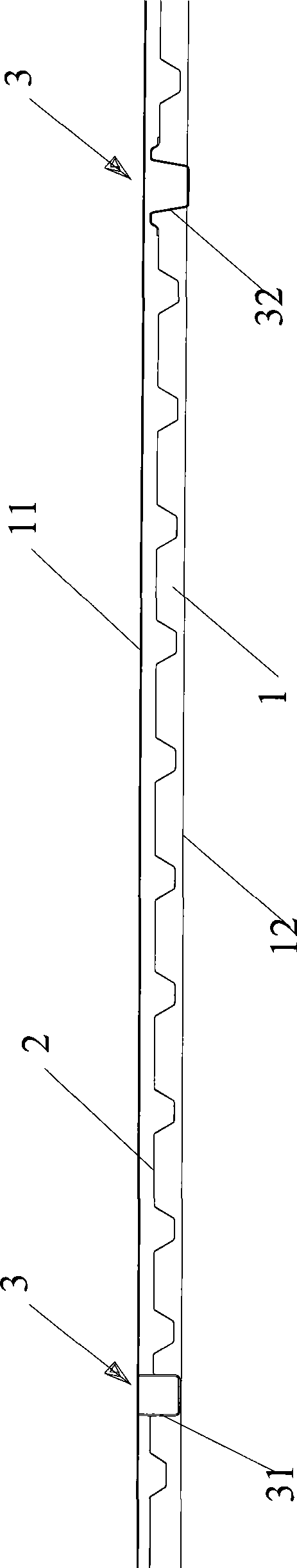

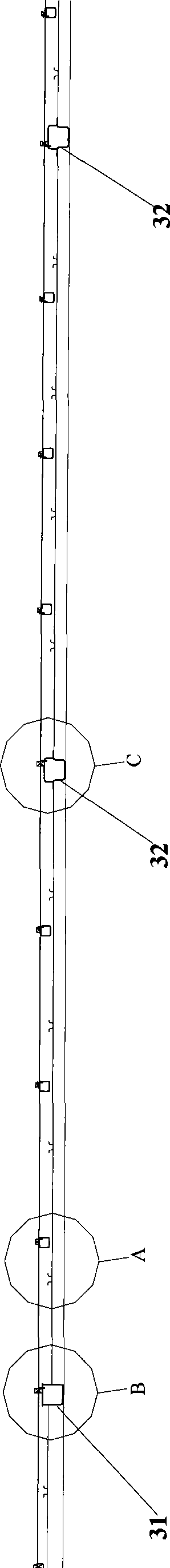

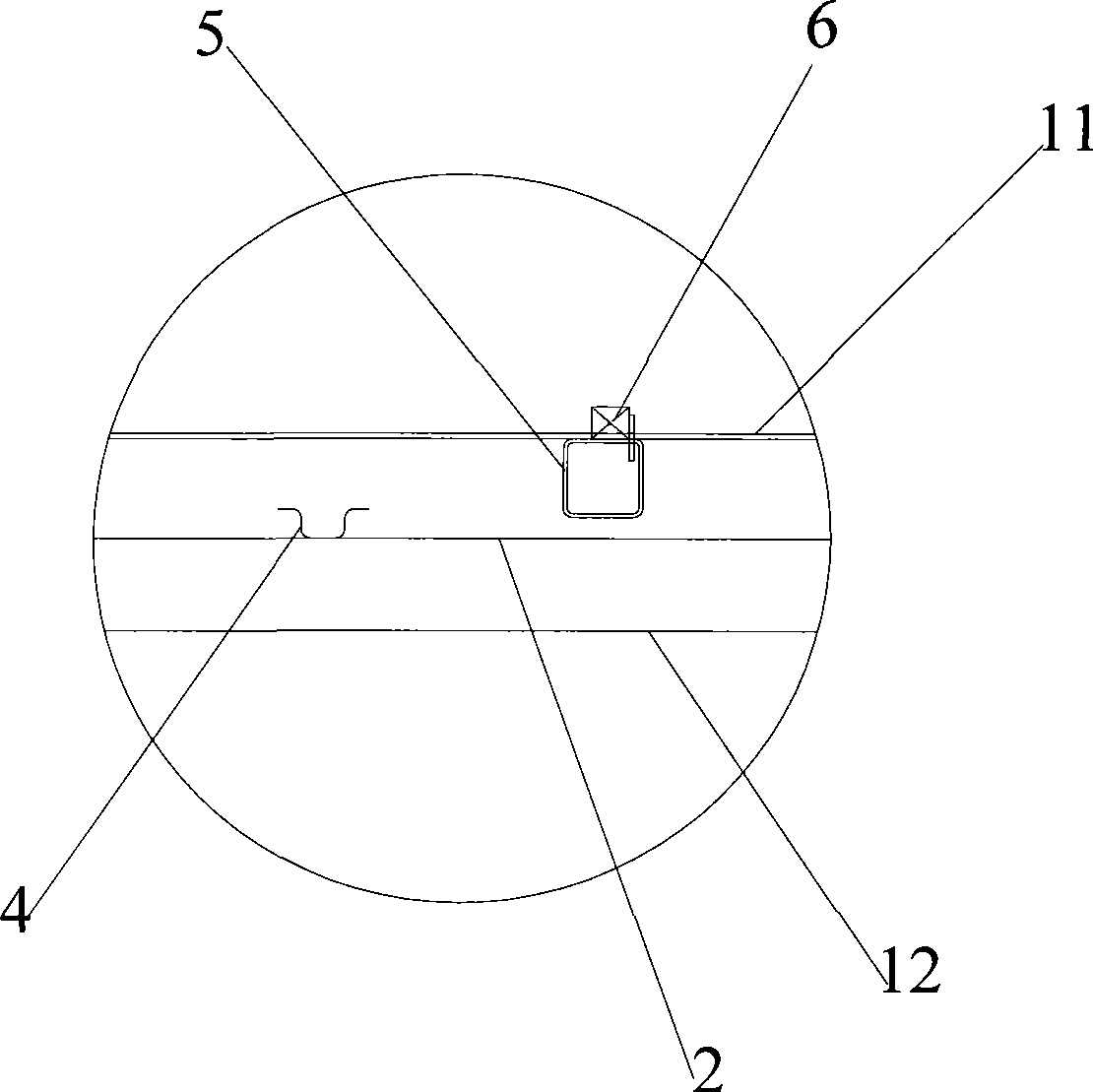

[0025] Embodiments of the present invention will now be described in detail with reference to the drawings. figure 2 It is a partial structural schematic diagram of the longitudinal section of the bottom frame of the refrigerated container of the present invention, image 3 , Figure 4 and Figure 5 respectively figure 2 Schematic diagram of the enlarged structure of parts A, B and C in the middle, Figure 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com