Inkjet printer and printing method

A technology of inkjet printer and inkjet head, which is applied to typewriters, printing devices, copying/marking methods, etc., and can solve the problems of limited location and high cost of inkjet printers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

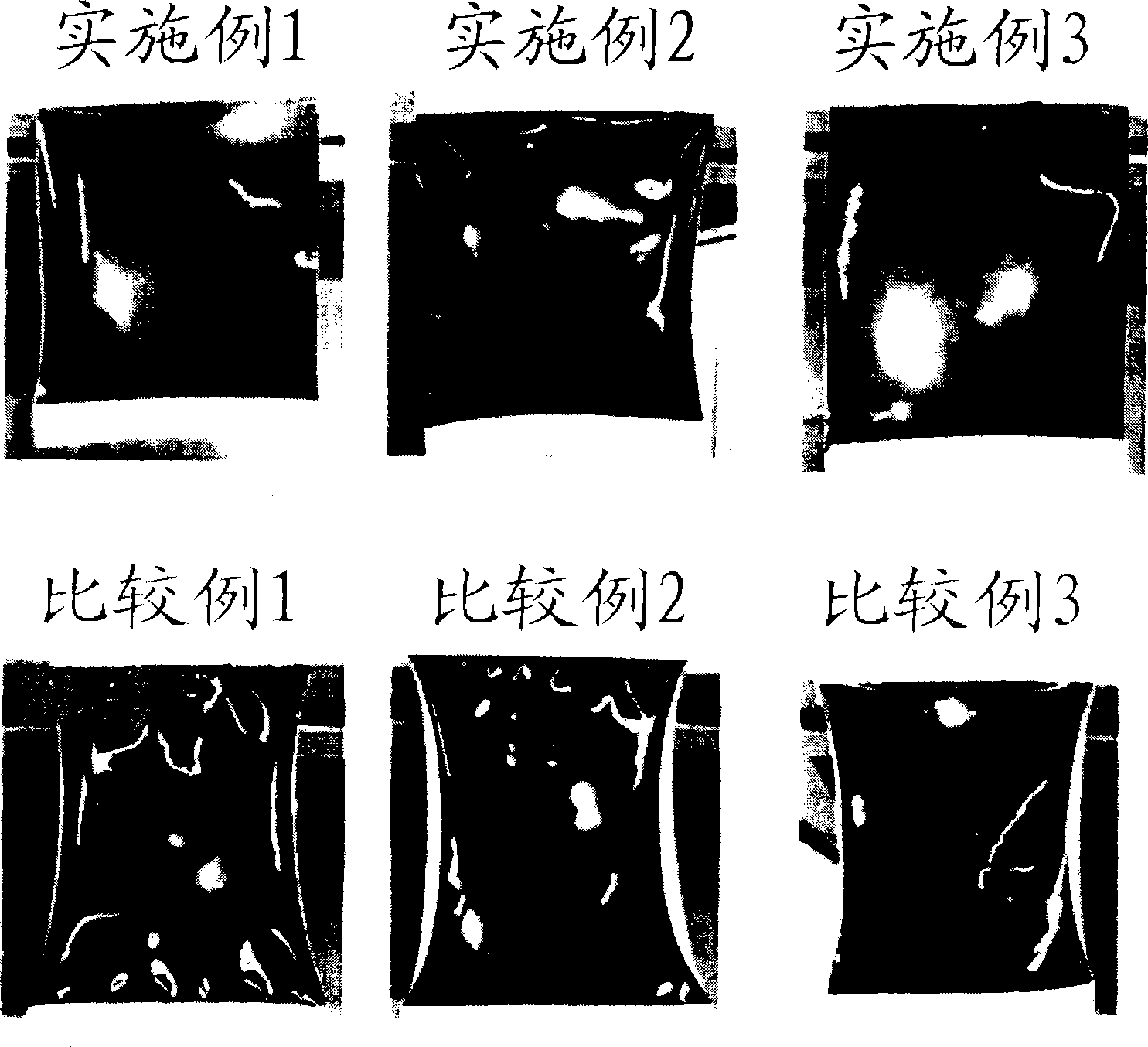

Embodiment 1~3

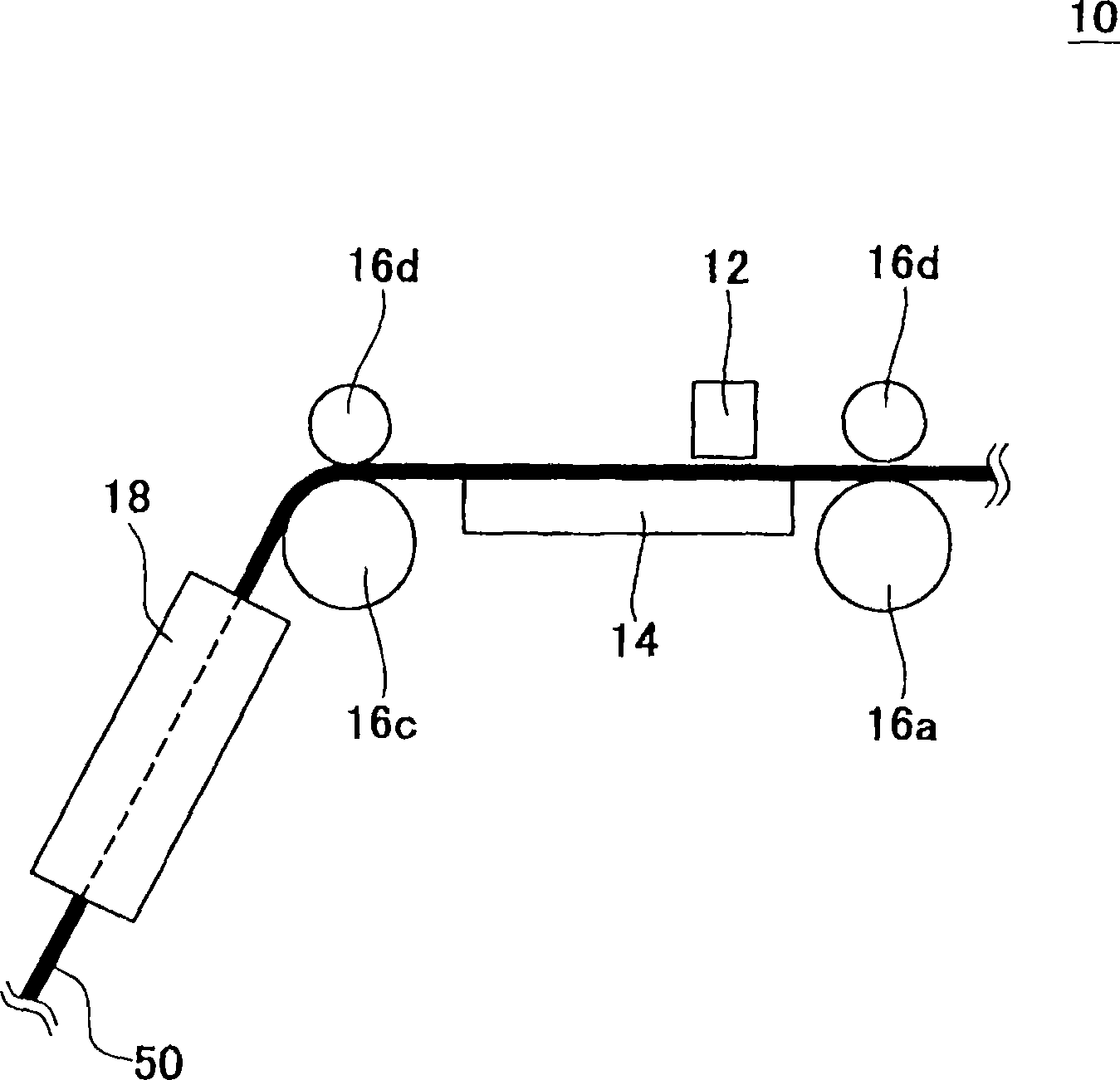

[0036] The printing described in Examples 1 to 3 was performed using an inkjet printer manufactured by Mimaki Engineering Co., Ltd. as the inkjet printer 10 . The model of the inkjet printer used in Examples 1 and 2 is JV33. In addition, the model of the inkjet printer used in Example 3 is JV5. Here, instead of the microwave generator provided on the main body of the inkjet printer 10 , a household microwave oven is used as the microwave irradiation unit 18 .

[0037] In addition, in Examples 1 to 3, solvent inks manufactured by Mimaki Engineering Co., Ltd. were used, respectively. The models of the solvent inks used in each example are ES3 (Example 1), SS21 (Example 2), and HS (Example 3). White polyethylene glossy paper with release paper was used as the medium 50 .

[0038] In each of the above configurations, the printing described in Embodiments 1 to 3 was performed. In this printing process, after the solvent ink was ejected by the inkjet printer 10 at a printing densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com