Container and packing method

A container and container body technology, applied in packaging and other directions, can solve problems such as damage and pollution of optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, modes for implementing the present invention will be described in detail with reference to the drawings.

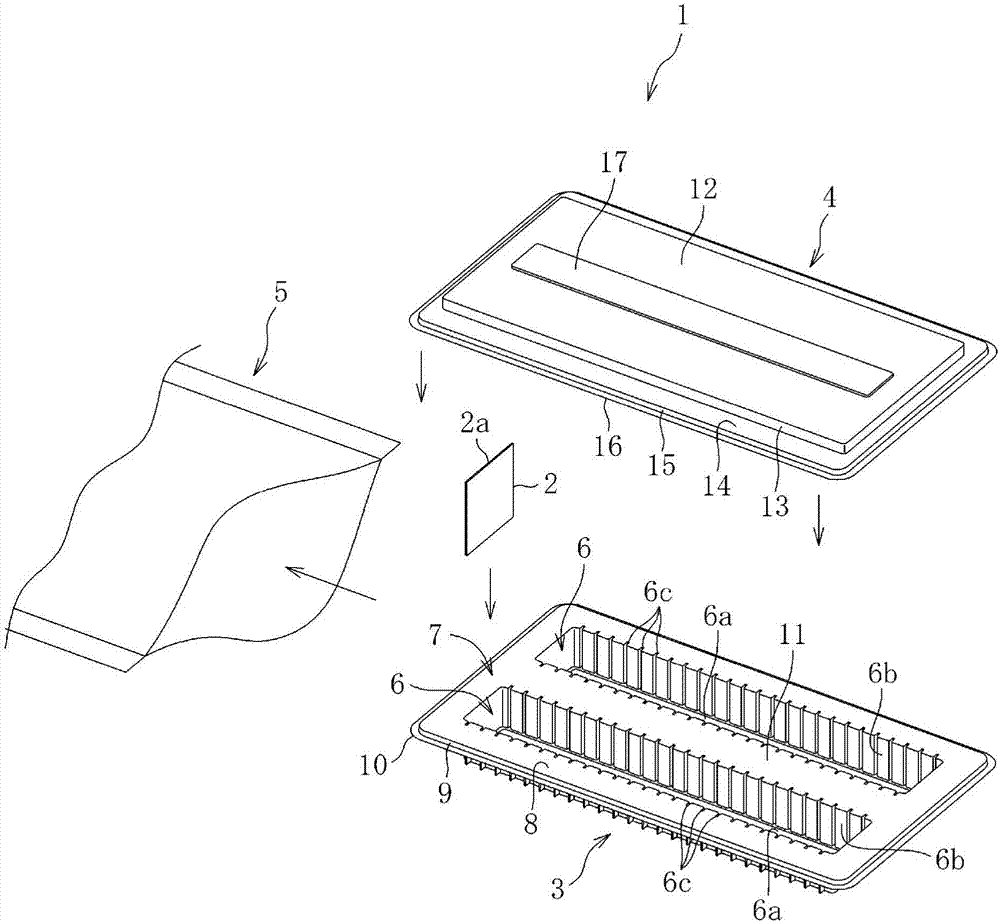

[0045] Figure 1 to Figure 8 The first embodiment of the container and packaging method according to the present invention is shown. Such as figure 1 As shown, the container 1 includes a container body 3 for accommodating an optical element 2 , a lid 4 covering the container body 3 , and a compression package 5 for compressing the container body 3 and the lid 4 . The container body 3 and the lid body 4 are made of, for example, a transparent resin material, and are formed into predetermined shapes by vacuum forming or other various forming methods.

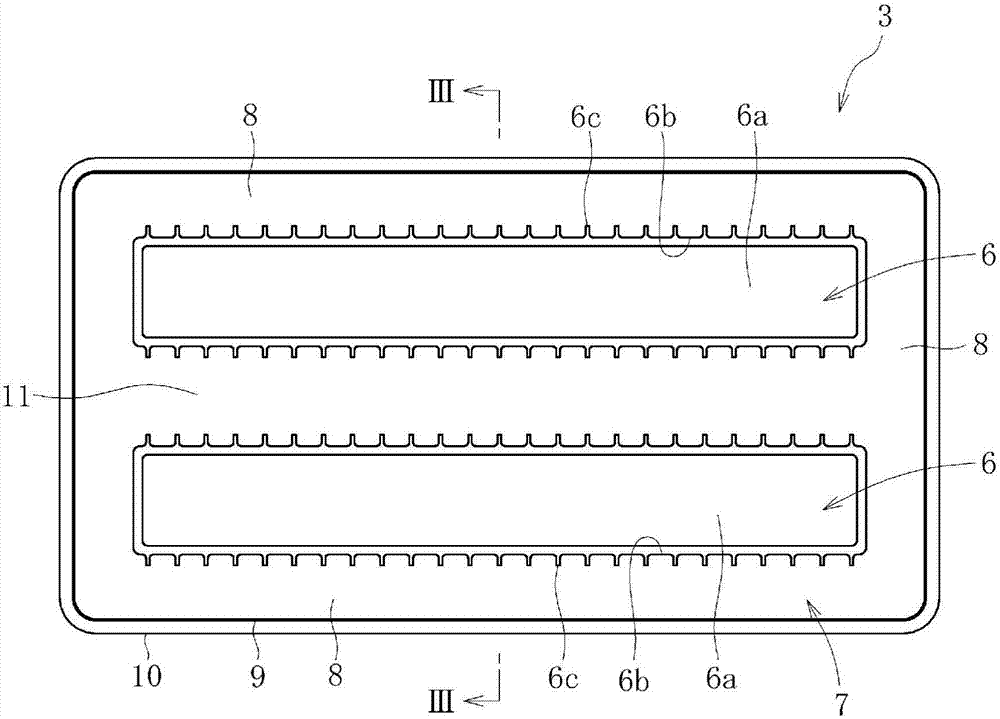

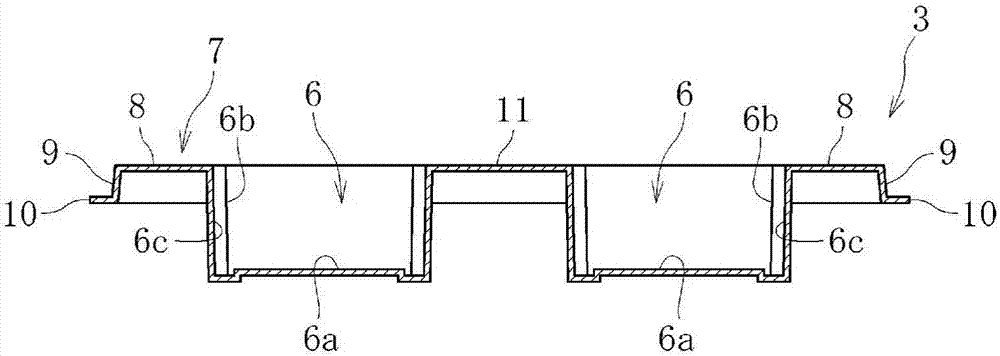

[0046] Such as Figure 1 to Figure 4 As shown, the container main body 3 includes: a housing portion 6 configured in a rectangular shape in plan view and capable of housing a plurality of optical elements 2 ; and a base portion 7 configured to surround the housing portion 6 .

[0047] The housing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com