Control system of numerical control servo press

A servo press and control system technology, applied in the numerical control field of presses, can solve the problems of inconvenient system upgrades and expansion of intelligent development and application, poor openness and adaptability, and complex systems, so as to facilitate upgrades and function expansion, and enhance openness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

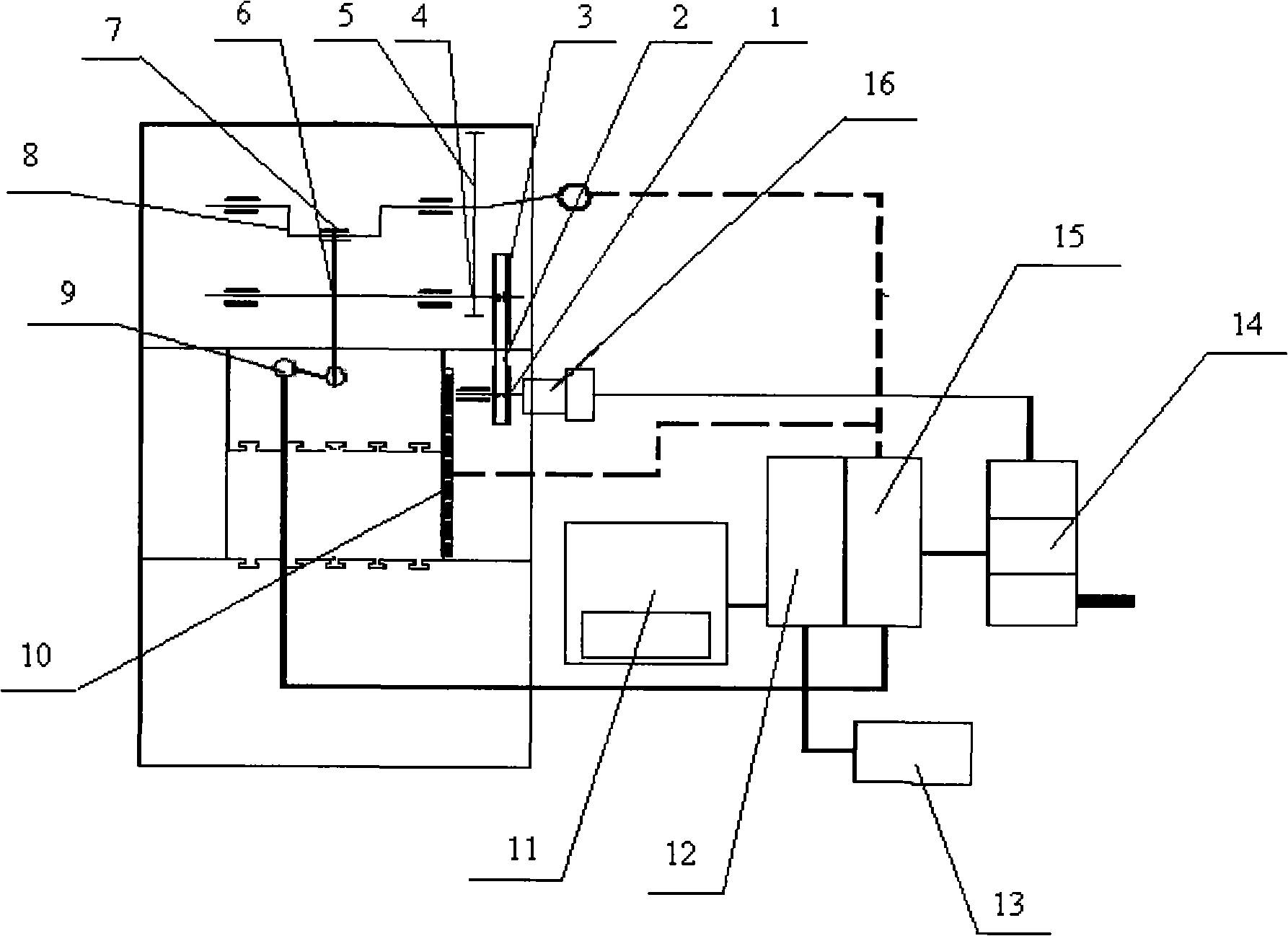

[0015] like figure 1 As shown in the control system of the CNC servo press, the industrial computer 12 , the operation panel 11 and the display 13 form a host computer subsystem, and the industrial computer 12 is connected to the PLC 15 through communication. In the sub-system of the lower computer, the PLC15 is connected to the drive motor 16 and the mold height adjustment motor 9 through the servo driver 14, and the motor passes through the first-stage synchronous belt (small pulley 1, transmission belt 2, large pulley 3) and the first-stage gear mechanism (pinion 4 And gearwheel 5) after decelerating, drive a crankshaft 8 to rotate, drive a toggle mechanism 6 to drive upper slide block 7 to realize ideal motion, grating scale 10 is in order to measure parameters such as the displacement of slide block, speed. Through the industrial computer, PLC module, grating ruler, and frequency converter, the real-time detection of the mold height and the closed-loop adjustment control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com