Turbocharger and cylinder head

A turbocharger and cylinder head technology, which is applied to cylinder heads, cylinders, machines/engines, etc., can solve problems such as error-prone costs, difficulty in connecting turbochargers and cylinder heads, etc., to save costs and reduce installation Effects of costs and parts reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

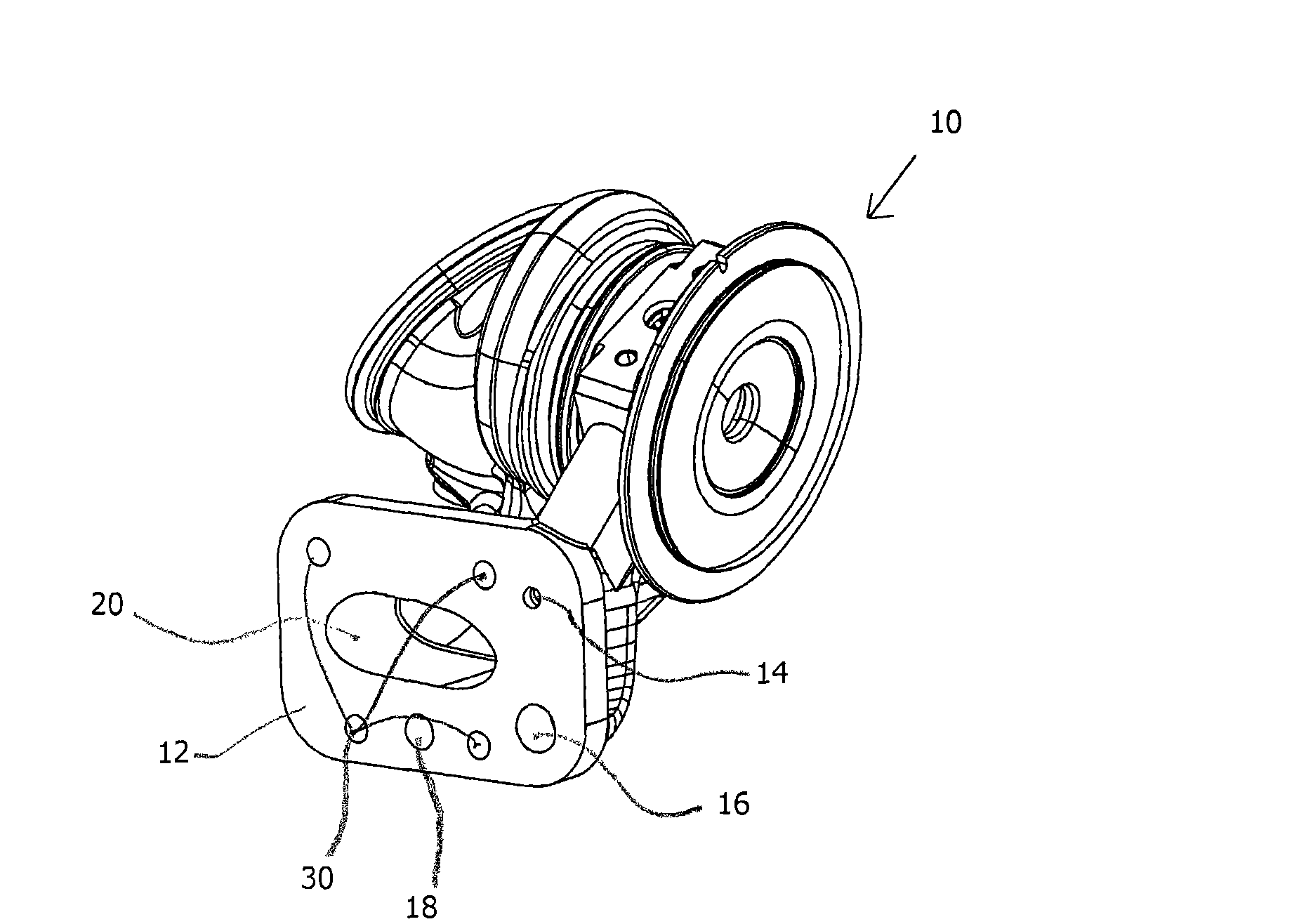

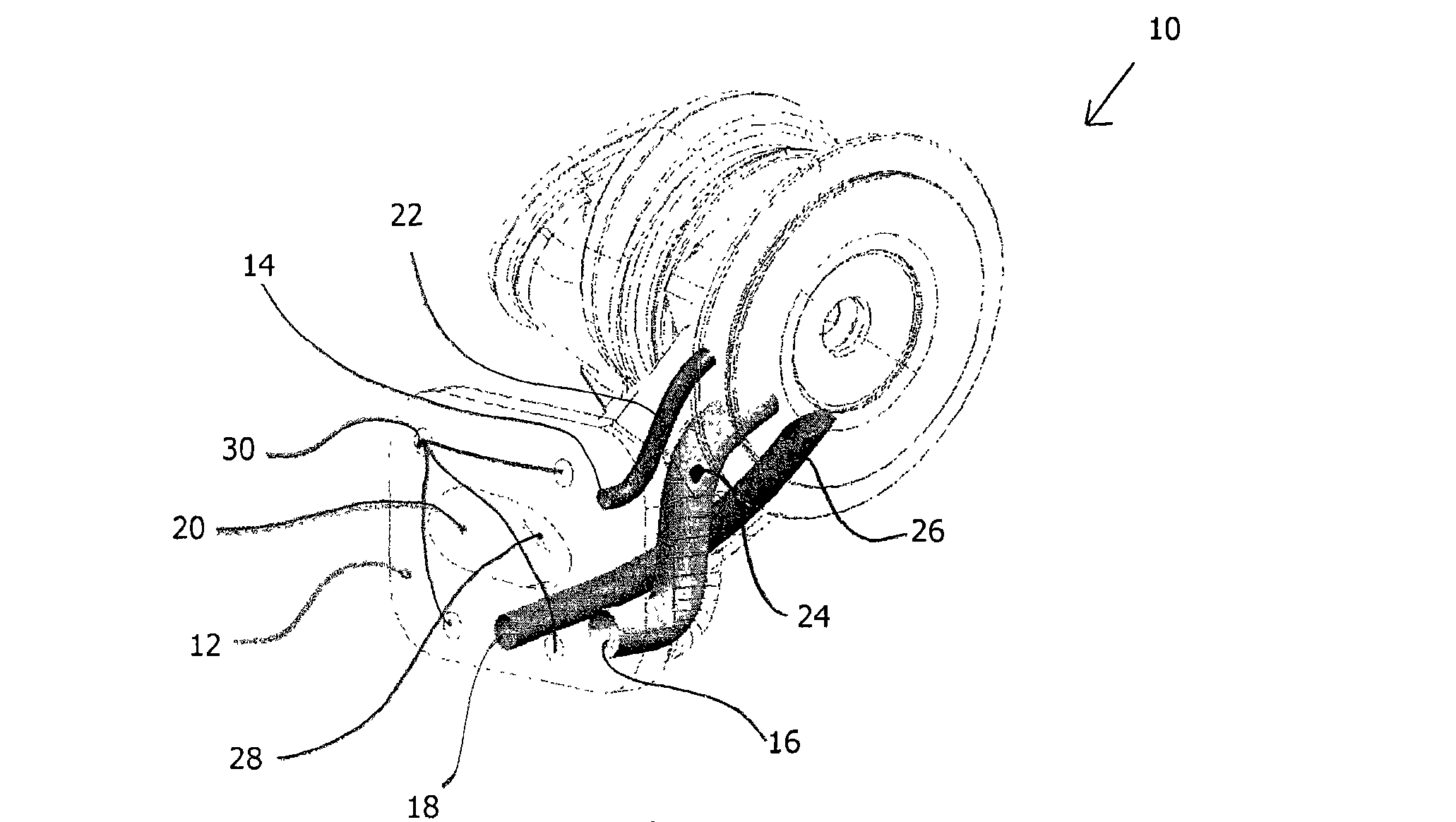

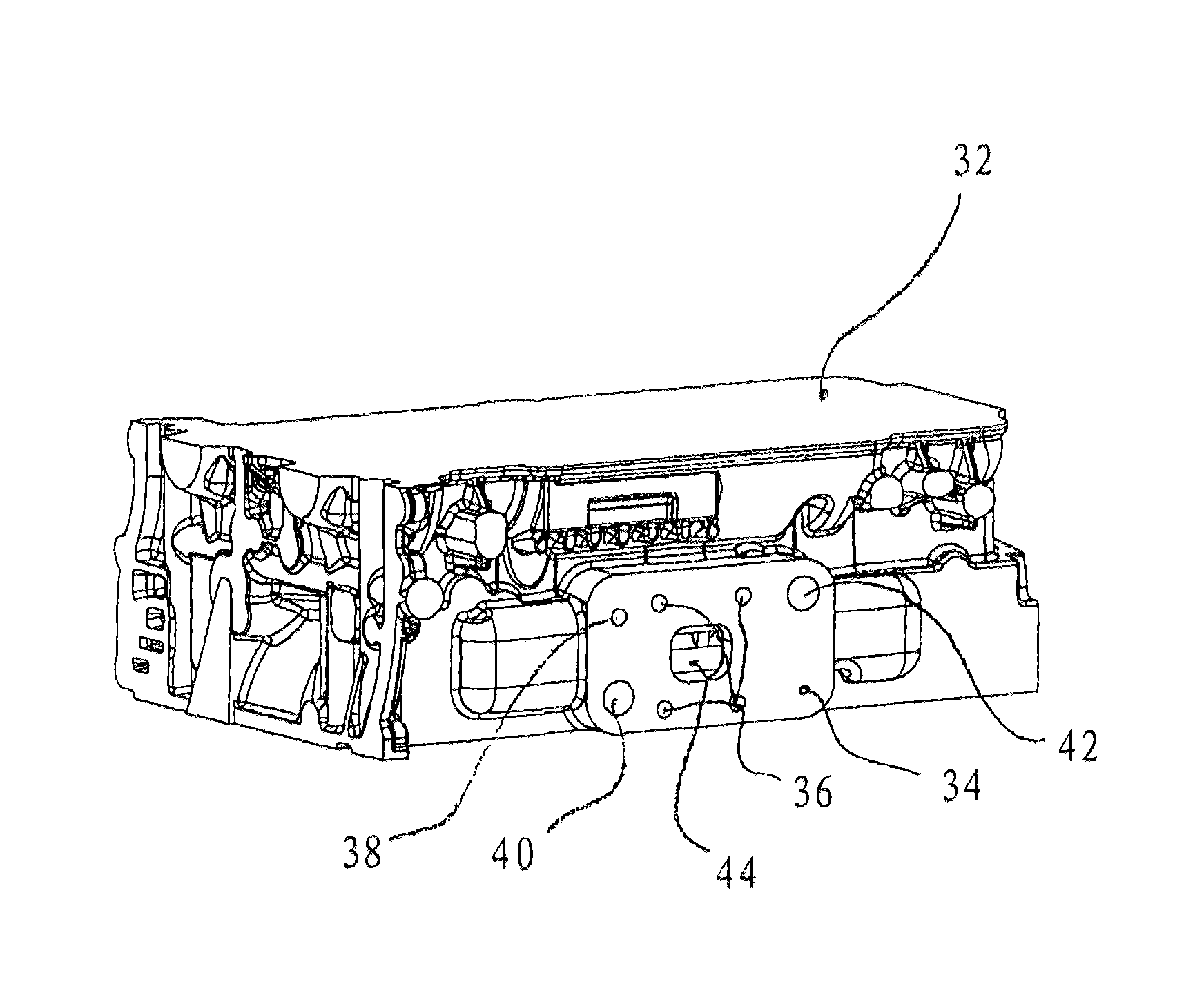

[0022] figure 1 and figure 2 The turbocharger 10 shown has a connecting flange 12 with a plurality of connecting holes 14 , 16 , 18 , 20 , wherein the connecting holes 14 , 16 , 18 , 20 can each receive a fluid for feeding and / or discharging a fluid. The fluid pipes 22, 24, 26, 28, or through the turbocharger 10 constitute. Here, the fluid lines 22 , 24 , 26 , 28 for conveying and / or discharging fluid can be, for example, the water supply line 26 of the turbocharger 10 for supplying sufficiently cold water, the pressurized oil supply line 22 , the oil return drain, etc. Oil pipe 24, exhaust gas discharge pipe 28 or crankcase fuel gas supply pipe. In the illustrated embodiment, the connection hole 14 accommodates a pressure oil supply line 22 , the connection hole 16 accommodates an oil return drain line 24 , the connection hole 18 accommodates a water supply line 26 and the connection hole 20 accommodates an exhaust gas discharge line 28 . According to the turbocharger 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com