Incision speed reducer for development machine of coal mine

A technology of reducer and roadheader, which is applied in the direction of slitting machinery, mechanical equipment, driving devices, etc., can solve the problems of reduced service life, safety and reliability, complex structure, and increased processing difficulty, so as to avoid weld stress concentration and simplify Box structure, the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

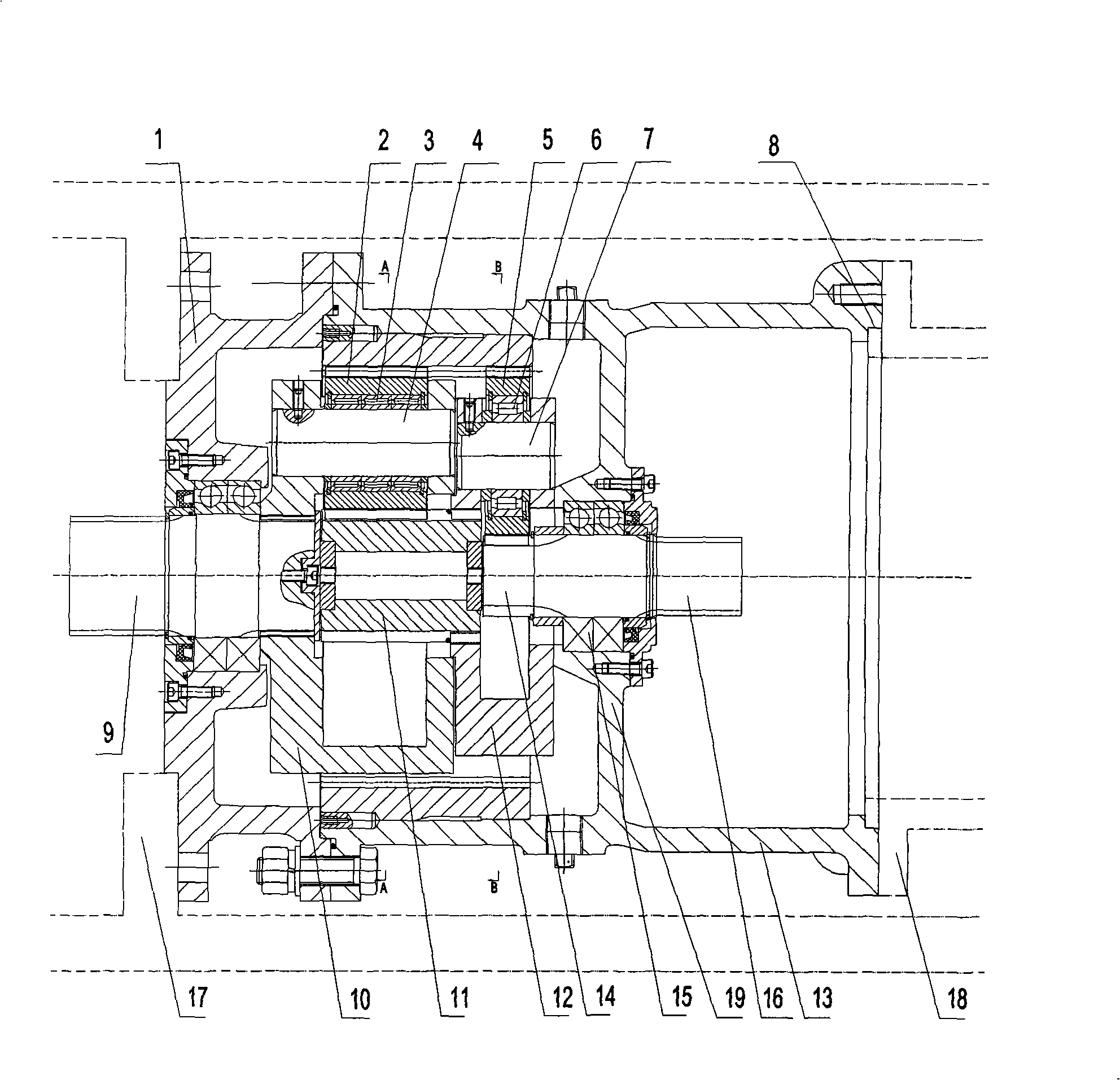

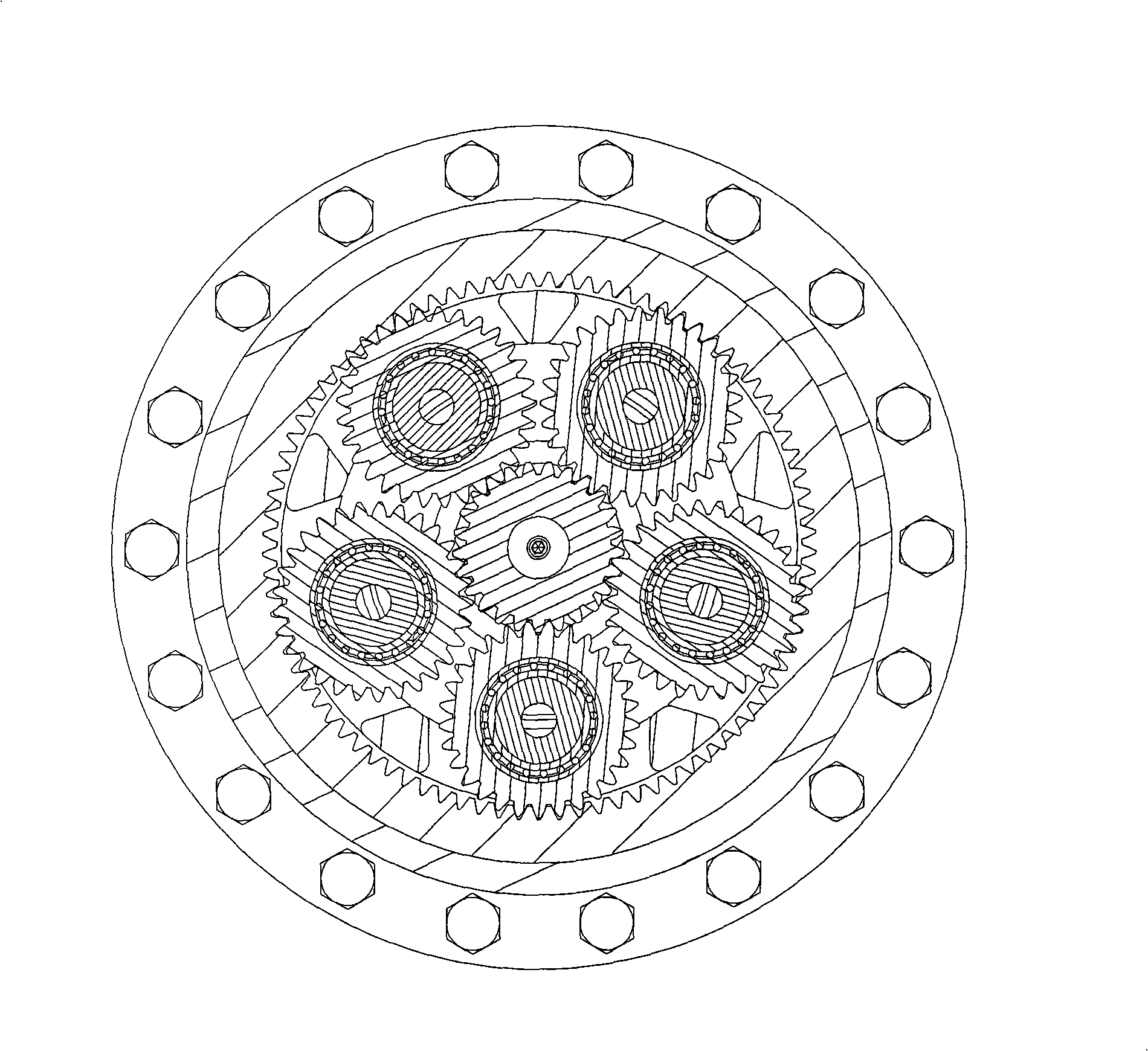

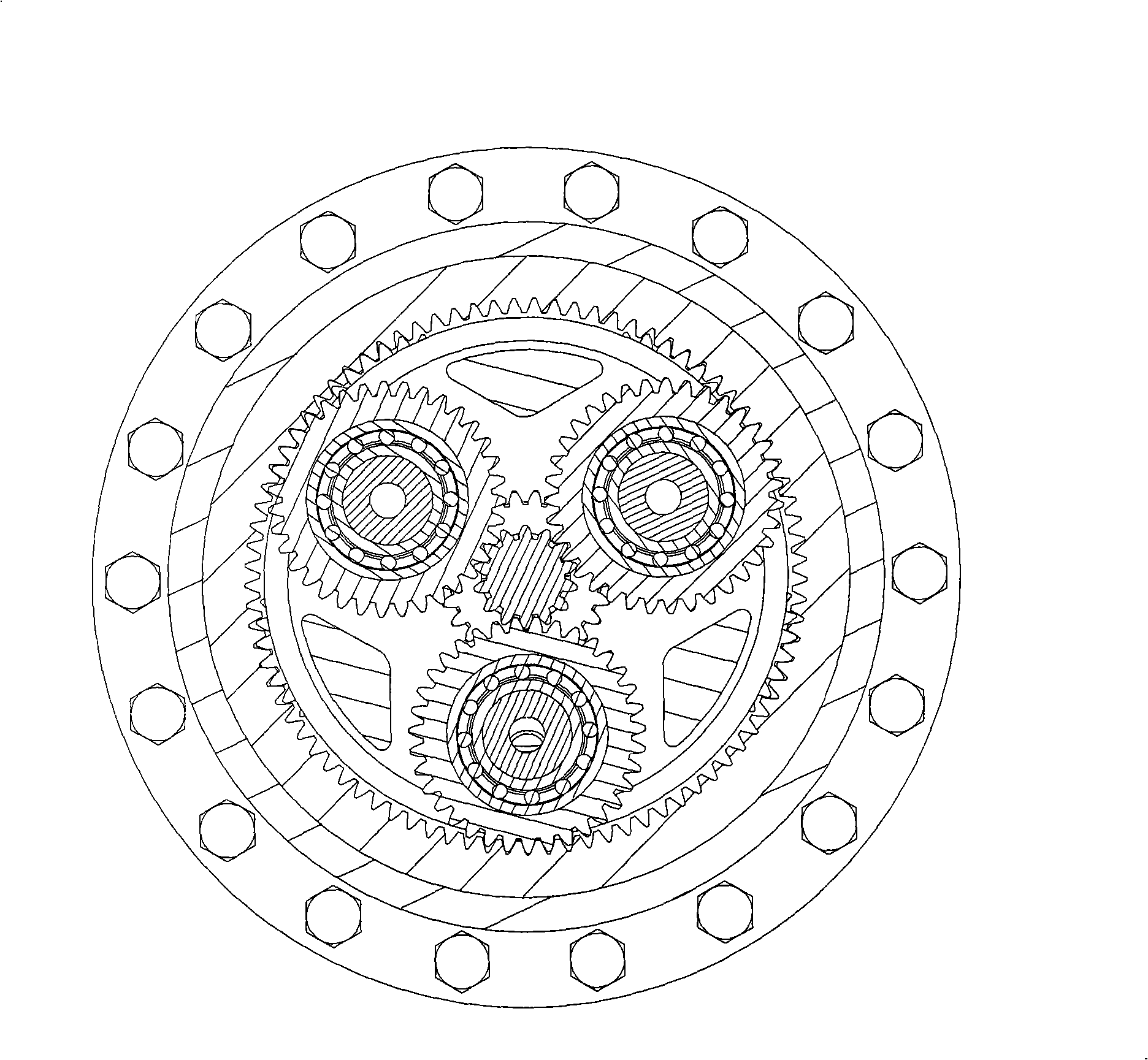

[0025] A coal mine roadheader cutting reducer, which consists of a box body 13, an input shaft 16, and a planetary reduction assembly placed in the box body 13 and connected with the input shaft 16. The input end and output end of the reducer box body 13 are respectively set There is a flange, the reducer case 13 is a cylinder with one end closed and one end open, the open end of the case 13 is closed by the case cover 1, a partition 19 is arranged inside the case 13, and the closed end of the reducer case 13 is provided with an input terminal. Lan 8, case cover 1 is the output end flange, and the input shaft bearing 15 supporting the input shaft 16 of the reducer is installed on the casing 13 inner partition 19. The input shaft 16 is connected with the motor 18, and the input power of the input shaft 16 by the motor 18 is 55KW. The planetary reduction assembly is provided with an output shaft 9 connected with the transmission shaft of the cutting head. The whole reducer is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com