Low-speed gear information case body

A gear and box technology, applied in the field of low-speed gear information boxes, can solve the problems of high hardware requirements, difficult diagnosis, and difficult identification of the acoustic emission method, and achieve improved detection accuracy and efficiency, low energy consumption detection and diagnosis, and box The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

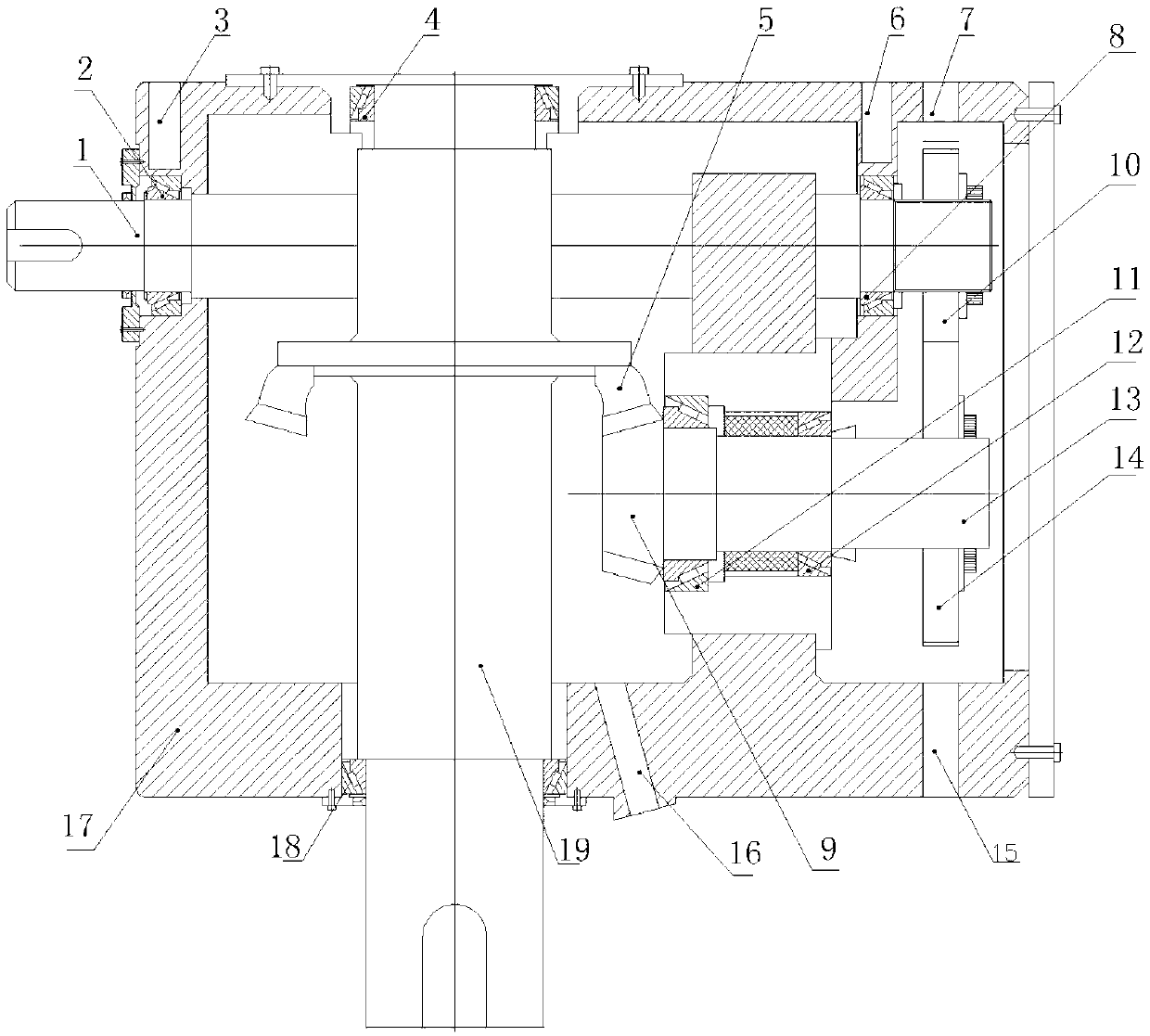

[0031] Such as figure 1 As shown, a low-speed gear information box includes a box 17, a high-speed input shaft 1, an intermediate shaft 13, and a low-speed output shaft 19, and a first tapered roller shaft is horizontally arranged on the left and right sides of the box 17. 2 and the second tapered roller shaft 8, the third tapered roller shaft 11 and the fourth tapered roller shaft 12 are arranged horizontally on the middle support wall of the box body 17, and are arranged longitudinally on the front and rear sides of the box body 17 There are fifth tapered roller shaft 4 and sixth tapered roller shaft 18;

[0032] The high-speed input shaft 1 is installed on the first tapered roller shaft 2 and the second tapered roller shaft 8, and the high-speed input shaft 1 is supported by the first tapered rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com