Urea production process of high-efficiency condensation, low-mounting height CO2 air stripping method and high-voltage lamp type full condensation reactor

A technology of installation height and reactor, which is applied in the preparation of urea derivatives, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of difficult and reasonable utilization, low steam pressure, and short residence time, and achieve investment saving and convenience. The effect of operation, easy maintenance and overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

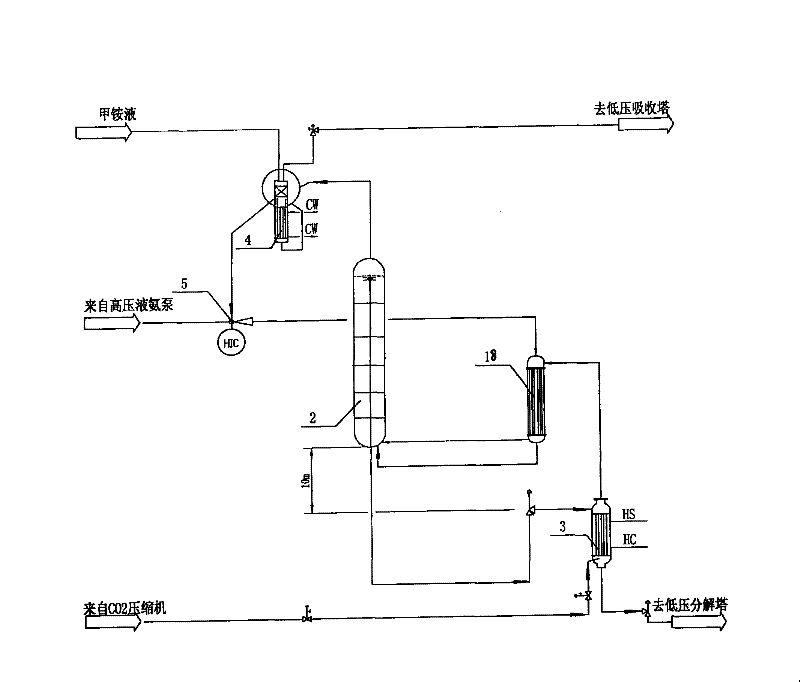

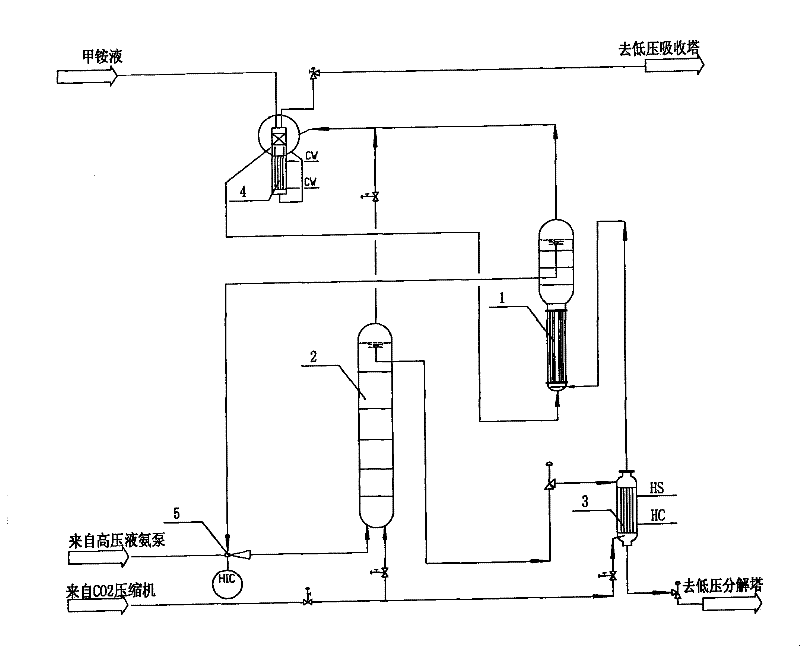

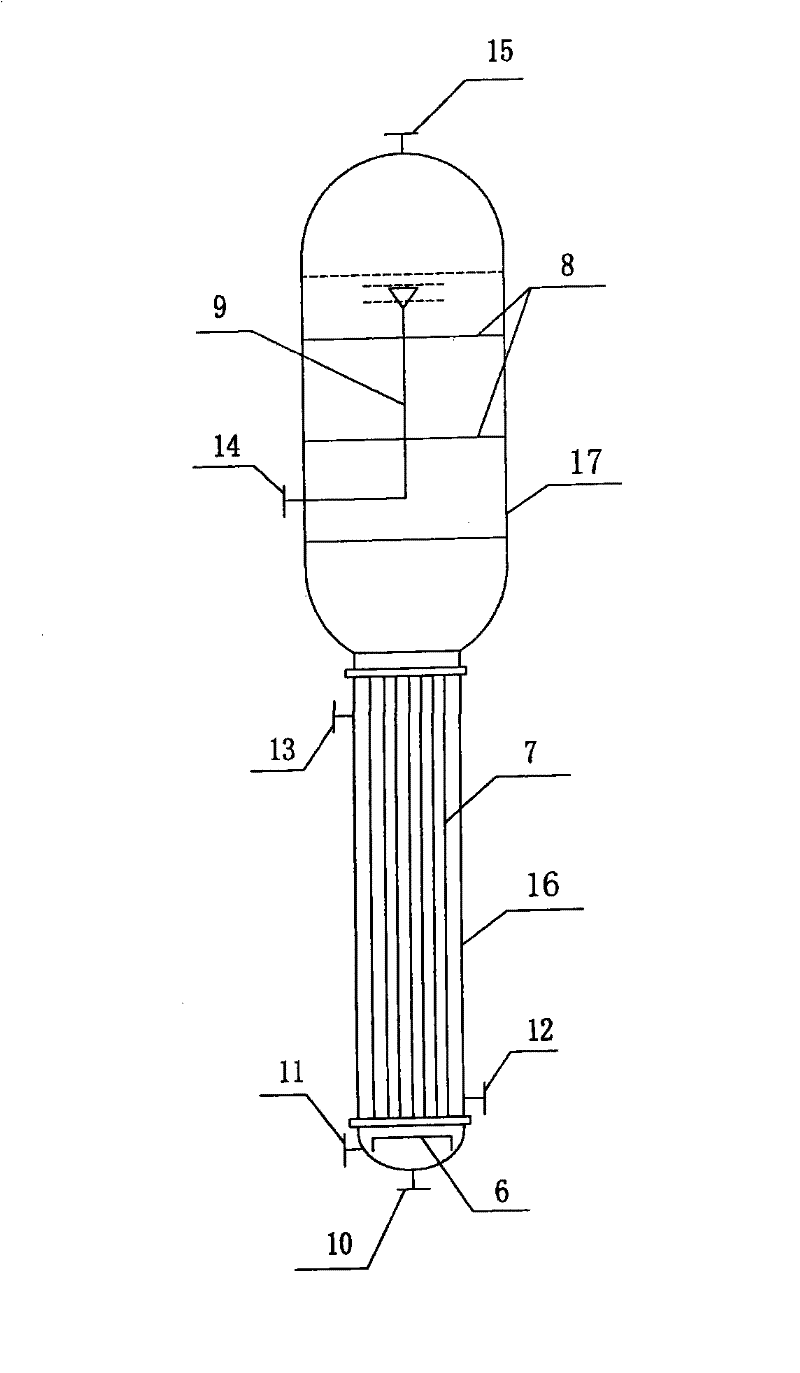

[0039] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0040] refer to figure 2 , in the high-pressure circle process, will be by CO 2 14.5MPa(A) compressed by the compressor, CO at 120°C 2 Gas, enters high pressure system in two parts, 75-85% CO 2 The gas enters the tube side of the high-pressure stripping tower 3 from the bottom, and the CO of 15-25% 2 The gas enters the urea synthesis tower 2 from the bottom to maintain its thermal balance; the high-pressure stripping tower 3 is a falling film heater, and the shell side is heated with 2.2MPa (A) steam to provide the ammonium carbamate decomposition source from the urea synthesis tower 2. The heat required, the stripping gas generated by the reaction (ie NH 3 and CO 2 Gas) enters the bottom tube side of the high-pressure tubular type total condensation reactor 1 from the top outlet of the high-pressure stripping tower 3 tube sides; NH in synthesis column 2 3 and CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com