Process for separating ethane nitrile wastewater with combination of abstraction and distillation

A process method and combined technology, applied in the field of separation of acetonitrile wastewater by combining extraction and rectification, can solve the problems of complex treatment methods, low separation efficiency, high equipment cost, etc., achieve improved recovery rate and acetonitrile product quality, and improve economic benefits , The effect of reducing energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

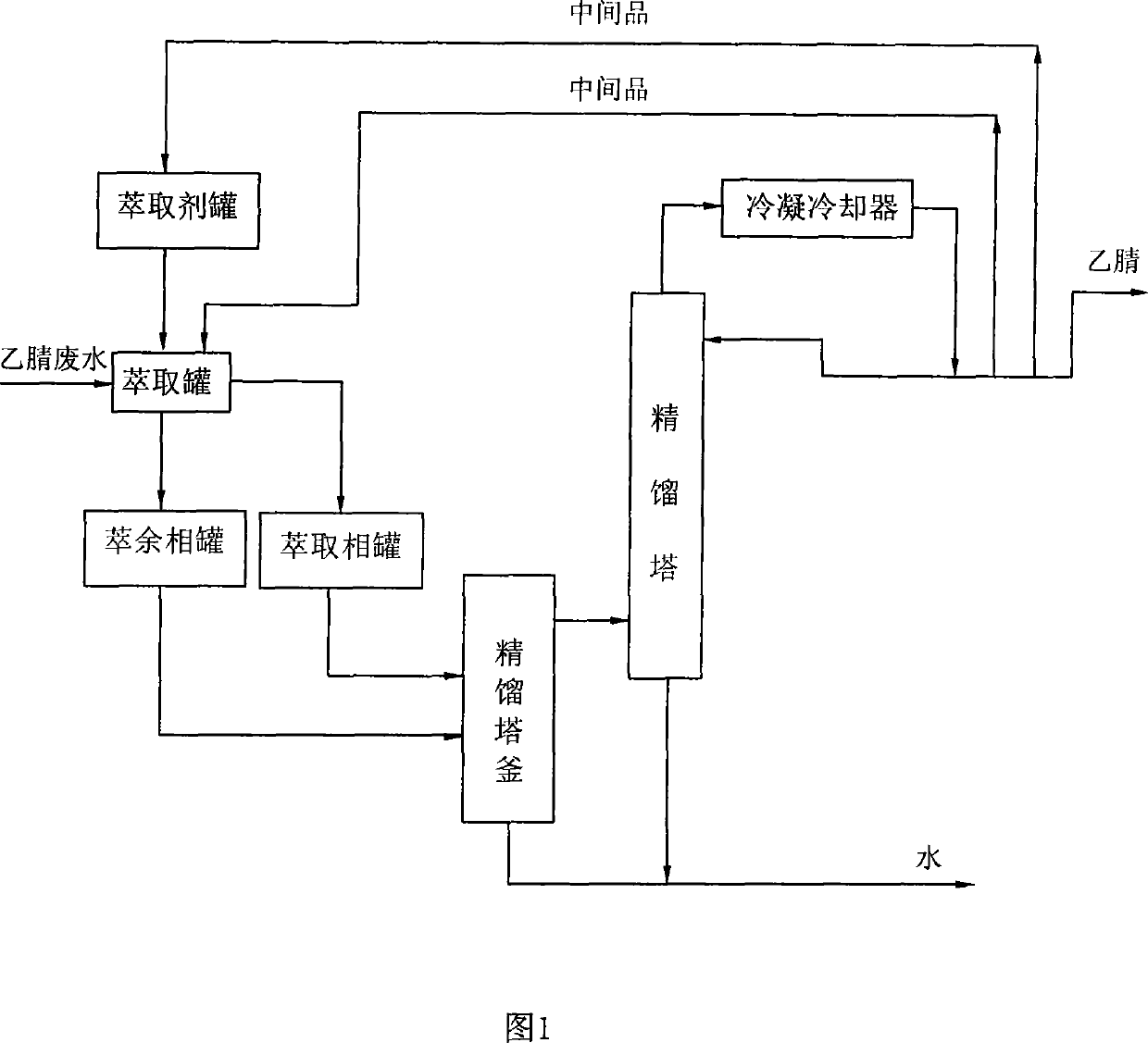

Image

Examples

Embodiment 1

[0020] A pharmaceutical factory produces acetonitrile waste water in the production process, the acetonitrile weight content in this acetonitrile waste water is about 20%, and the rest is a small amount of pharmaceutical by-products and water, and its treatment steps are as follows:

[0021] (1). Under normal temperature and pressure, use a 3L glass cup as the extraction tank, add 1L of acetonitrile waste water in each batch, and then add 0.8L of dichloromethane. After fully stirring for half an hour, the mixture will be extracted; the mixture will be allowed to stand Half an hour later, the mixture was divided into two layers: the lower layer was the extract phase, which was a heavy phase with a volume of about 1.1 L and acetonitrile weight content of about 13%; the upper layer was a raffinate phase, and the raffinate phase was a light phase. The volume is about 0.7L, mainly water, and the weight content of acetonitrile is about 2.2%;

[0022] (2). Put the extract phase of th...

Embodiment 2

[0027] A pharmaceutical factory produces 5m per day in the production process 3 Acetonitrile waste water, the acetonitrile weight content in this acetonitrile waste water is about 28%, and all the other are a small amount of pharmaceutical by-products and water, and its treatment steps are as follows:

[0028] (1). At normal temperature and pressure, use 6.3m 3 The enamel stirring tank is used as the extraction tank, and each batch is added with 2.5m 3 Acetonitrile wastewater, then add 2.5m 3 Dichloromethane, fully stirred for 2 hours, the mixed solution was extracted; then the mixed solution was left to stand for half an hour, and the mixed solution was divided into two layers: the lower layer was the extraction phase, and the extraction phase was the heavy phase, with a volume of about 3.2m 3 , the weight content of acetonitrile is about 15%; the upper layer is the raffinate phase, and the raffinate phase is the light phase with a volume of about 1.8m 3 , mainly water, th...

Embodiment 3

[0035] A pharmaceutical factory produces 2m per day in the production process 3 Acetonitrile waste water, the acetonitrile weight content in this acetonitrile waste water is about 15%, all the other are a small amount of pharmaceutical by-products and water, and solution is acidic, and its processing steps are as follows:

[0036] (1). At normal temperature and pressure, use 6.3m 3 The enamel stirring tank is used as the extraction tank, and the acetonitrile wastewater is added to the extraction tank at one time, and then 1.8m 3 Dichloromethane, fully stirred for 2 hours, and the mixture was extracted; then the mixture was left to stand for half an hour, and the mixture was divided into two layers: the lower layer was the extraction phase, and the extraction phase was the heavy phase, with a volume of about 2.2m 3 , the weight content of acetonitrile is about 11%; the upper layer is the raffinate phase, and the raffinate phase is the light phase with a volume of about 1.6m 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com