Low-resistance anti-block vertical flow wetland structure

A vertical flow wetland and anti-clogging technology, which is applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as difficult to clean, easy to block, and large water resistance, and achieve Save land, prevent clogging, and distribute water evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

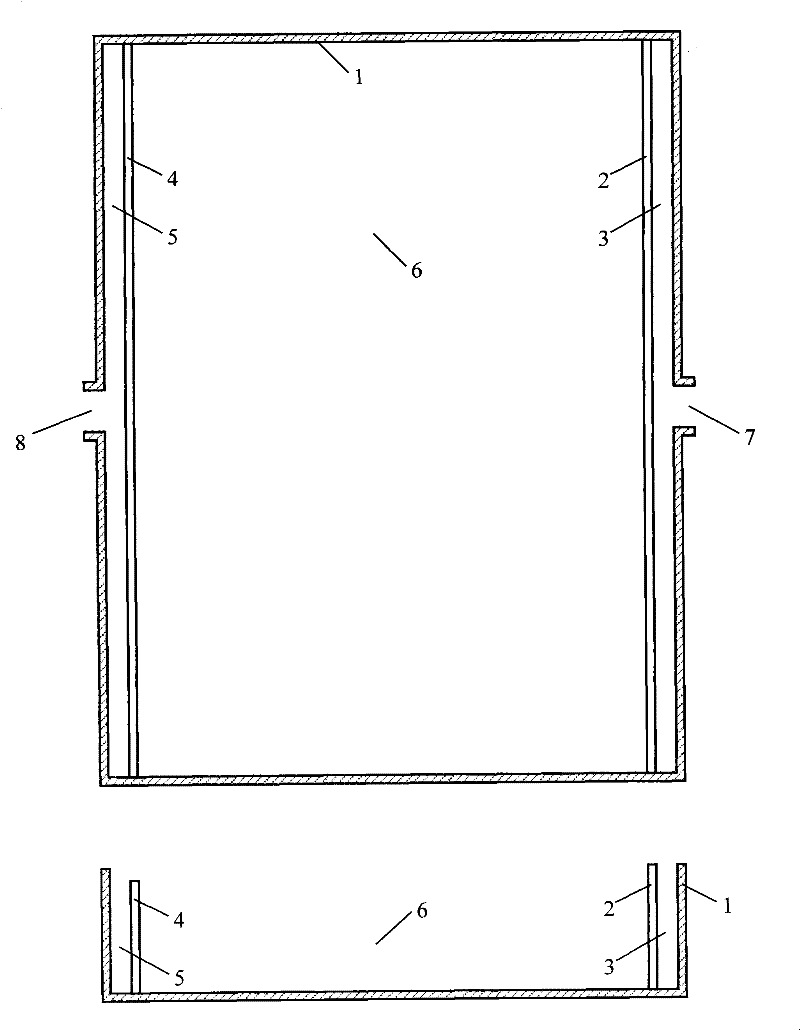

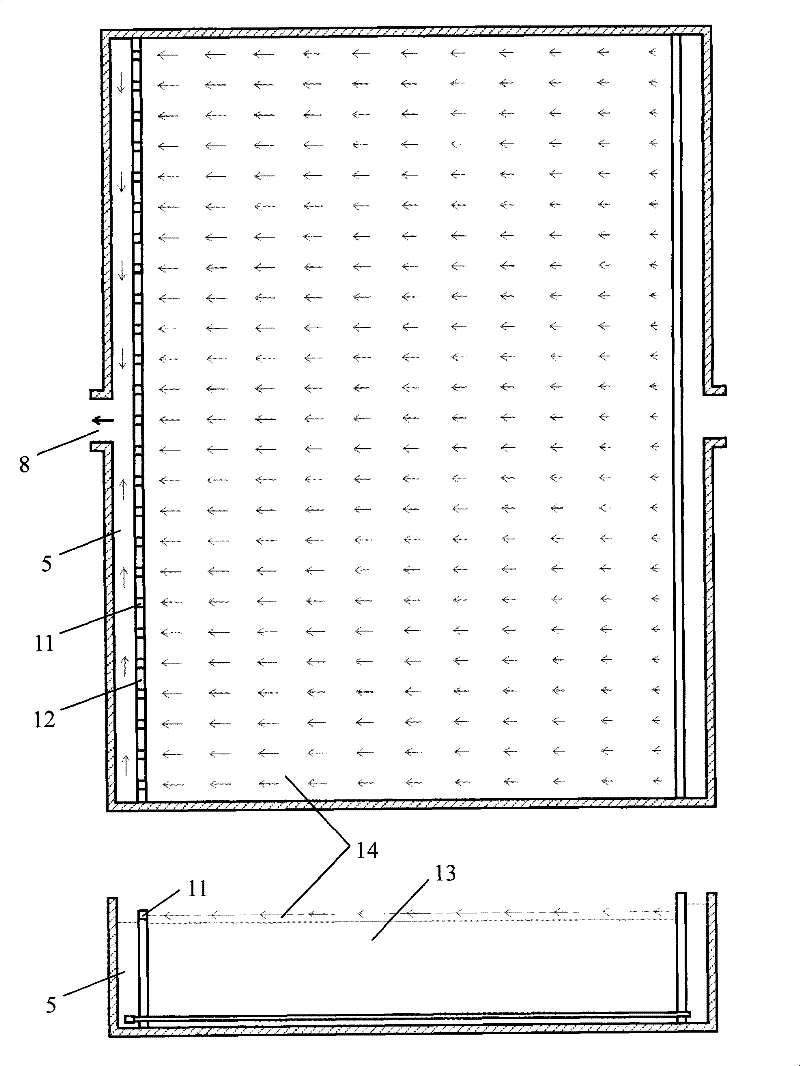

[0033] The present invention carries out engineering application according to the following steps:

[0034] (1) According to the flow requirements and geological conditions, design and build a hard pool body, and cut a "V"-shaped weir on the top of the ditches separating the pools.

[0035] (2) Fill the gravel cushion in the filler tank to the height where the water distribution pipe is installed.

[0036] (3) Drill holes at a specific height on the ridge of the separation pool, install water distribution pipes, and build a protective cover with dry bricks.

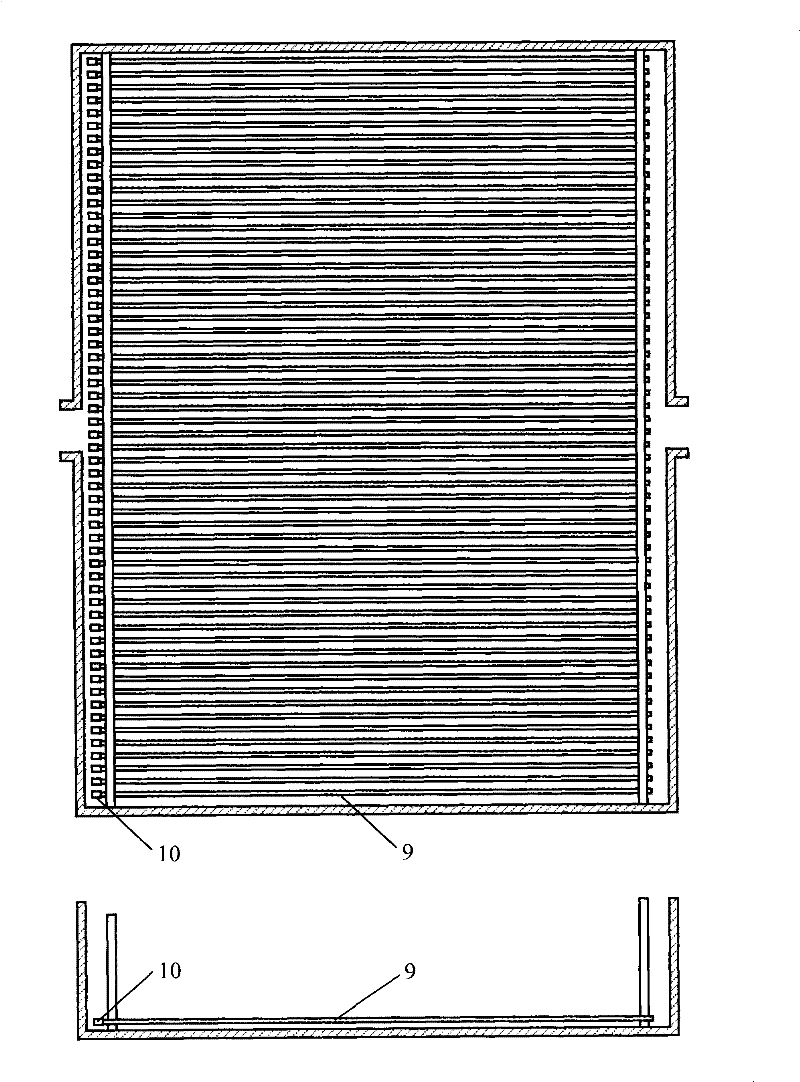

[0037] (4) Fill the filler pool with gravel (or other fillers) to a height of 100-150 mm below the bottom of the "V"-shaped weir.

[0038] (5) Inject water into the distribution ditch and the water collection ditch at the same time to the height of the bottom of the "V" shaped weir.

[0039] (6) Plant hygrophytes in the filling pond, maintain the water level and maintain and manage them until they survive.

[0040] (7)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com