Safety protection deice for engineer working vehicle

A technology for safety protection devices and working vehicles, applied in the field of safety protection devices, can solve the problems of immeasurable direct losses and indirect losses, difficulty in judging the exact position of the operation switch, no light display and backup protection, etc., to achieve easy promotion and safety protection Good effect, easy to promote the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

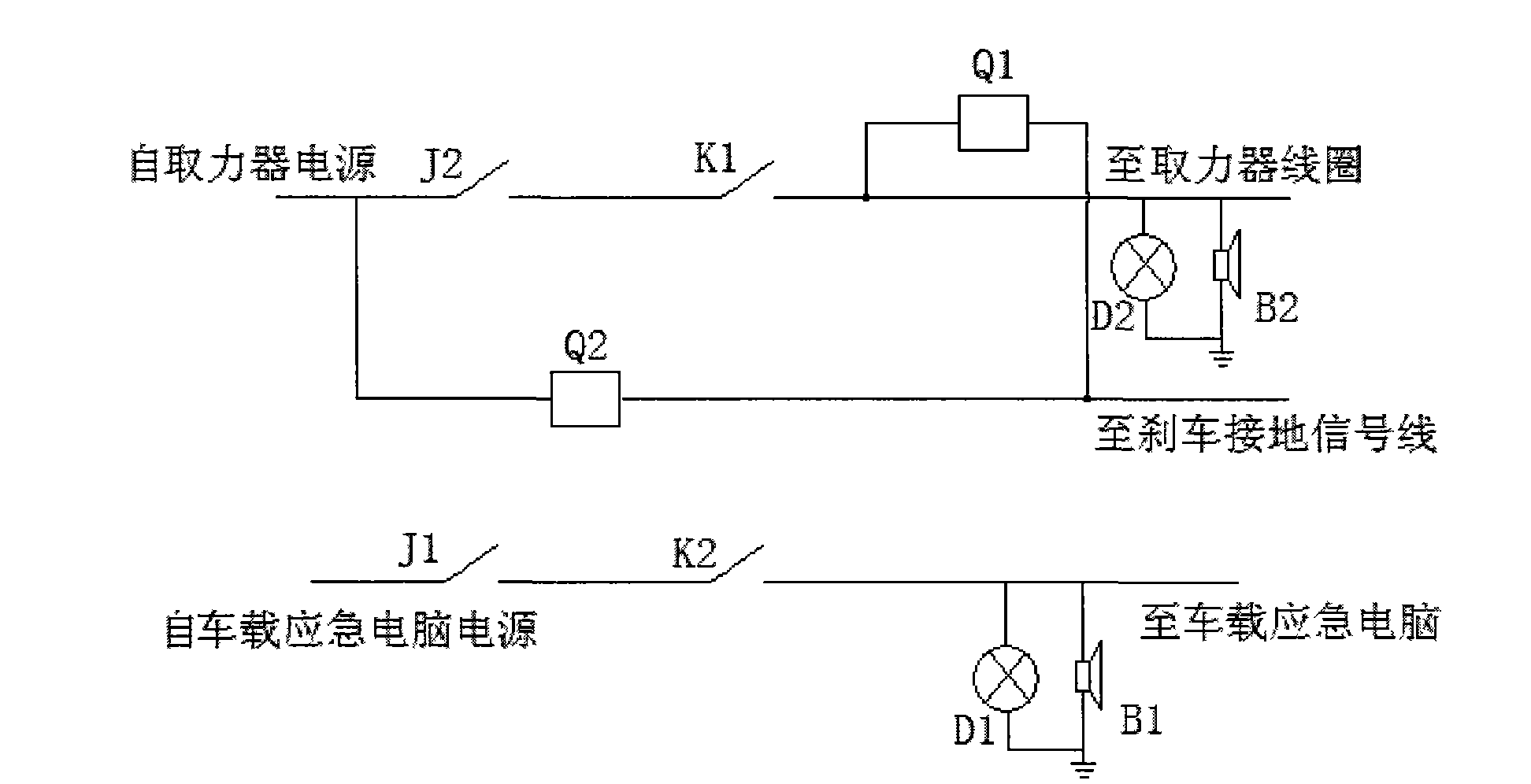

[0017] Such as figure 2 As shown, the device of the present invention is installed in the cab, including the first intermediate relay Q1 and the second intermediate relay Q2, wherein one end of the coil of the second intermediate relay Q2 is connected to the power supply of the power take-off, and the other end is connected to the brake grounding signal line. The normally open contact J2 of the second intermediate relay Q2 and the power take-off switch K1 are connected in series to the power line of the on-board emergency computer; one end of the coil of the first intermediate relay Q1 passes through the normal contact of the power take-off switch K1 and the second intermediate relay Q2 The open contact J2 is connected to the power supply of the power take-off, and the other end is connected to the brake grounding signal. The normally open contact J1 of the first intermediate relay Q1 and the vehicle emergency computer switch K2 are connected in series to the power line of the...

Embodiment 2

[0022] In this embodiment, the insulating arm truck is taken as an example. The difference from Embodiment 1 is that the device of the present invention is installed in the driver's cab of the insulated bucket truck. When the vehicle is in neutral, parked, and working at heights, there is a brake grounding signal, the power take-off switch is closed, the coil of the first intermediate relay Q1 is charged, and the normally open contact J1 set on the power line of the on-board emergency computer is closed , turn the on-board emergency computer switch K2 to the closed position, and the on-board emergency computer works. If the engine stalls, the on-board emergency computer will automatically start the emergency hydraulic pump, retract the insulated bucket arm from high altitude, and let the staff fall to the ground safely.

Embodiment 3

[0024] Taking the various special vehicles equipped with hydraulic pumps on the chassis as an example, the difference from Embodiment 1 or 2 is that the device of the present invention is installed in the cabs of special vehicles equipped with hydraulic pumps on various chassis. In the prior art, if you forget to turn off the power take-off switch K1, the pressure of the hydraulic pump is proportional to the speed of the vehicle when the vehicle is running, and the pressure on the hydraulic pipeline is several times the rated pressure, and the hydraulic pipeline will be damaged due to excessive pressure. Cause fatigue, prone to sudden pipe burst, gearbox, transfer case and easily damaged. If the vehicle installed with the device of the present invention forgets to turn off the power take-off switch K1 before starting, the hand brake is released, there is no brake grounding signal, the power take-off coil is not charged, the hydraulic pump cannot work, and the vehicle runs norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com