Liquid ejecting apparatus and liquid ejecting method

A liquid and driving signal technology, applied in printing and other directions, can solve problems such as poor ink ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

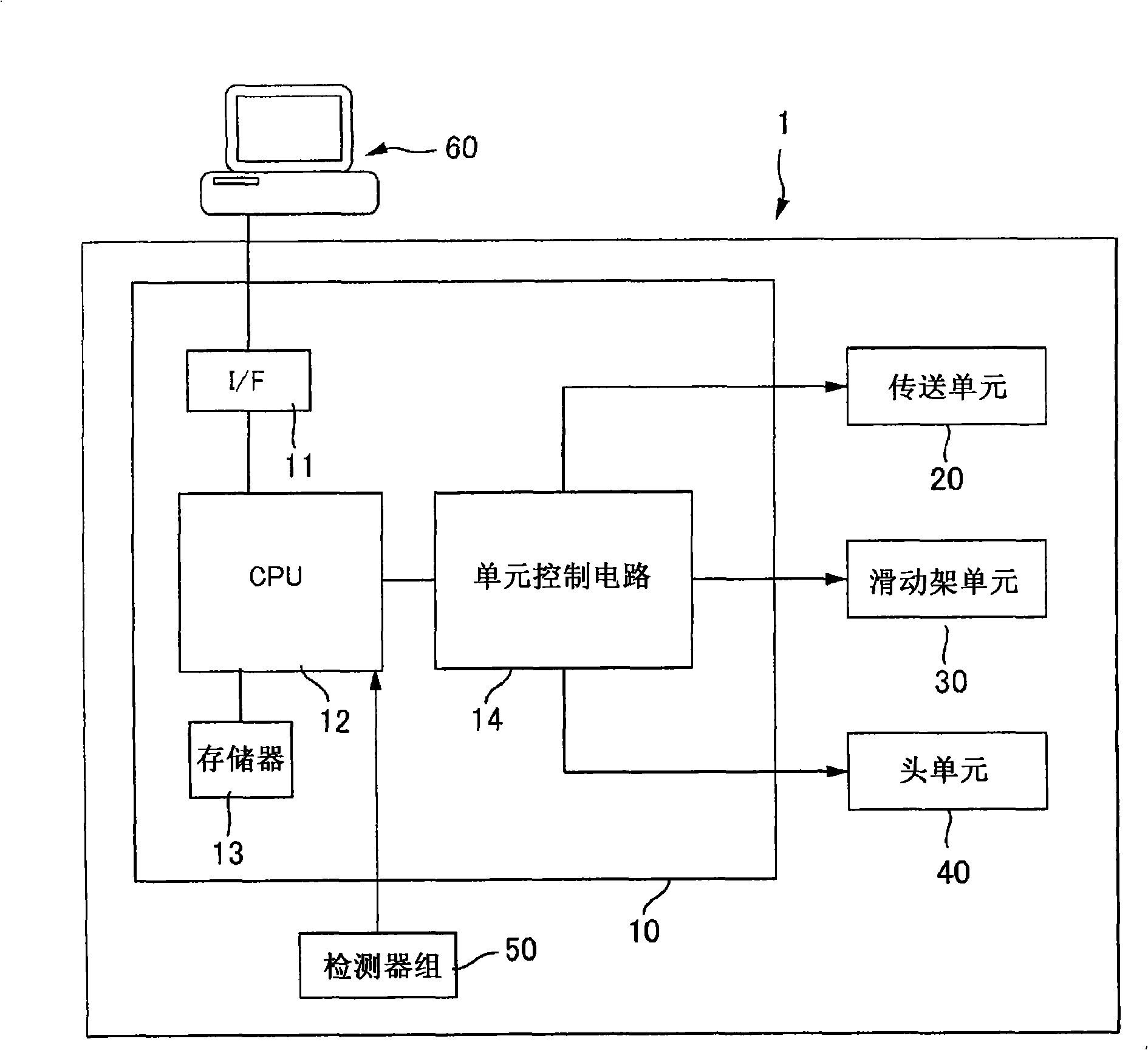

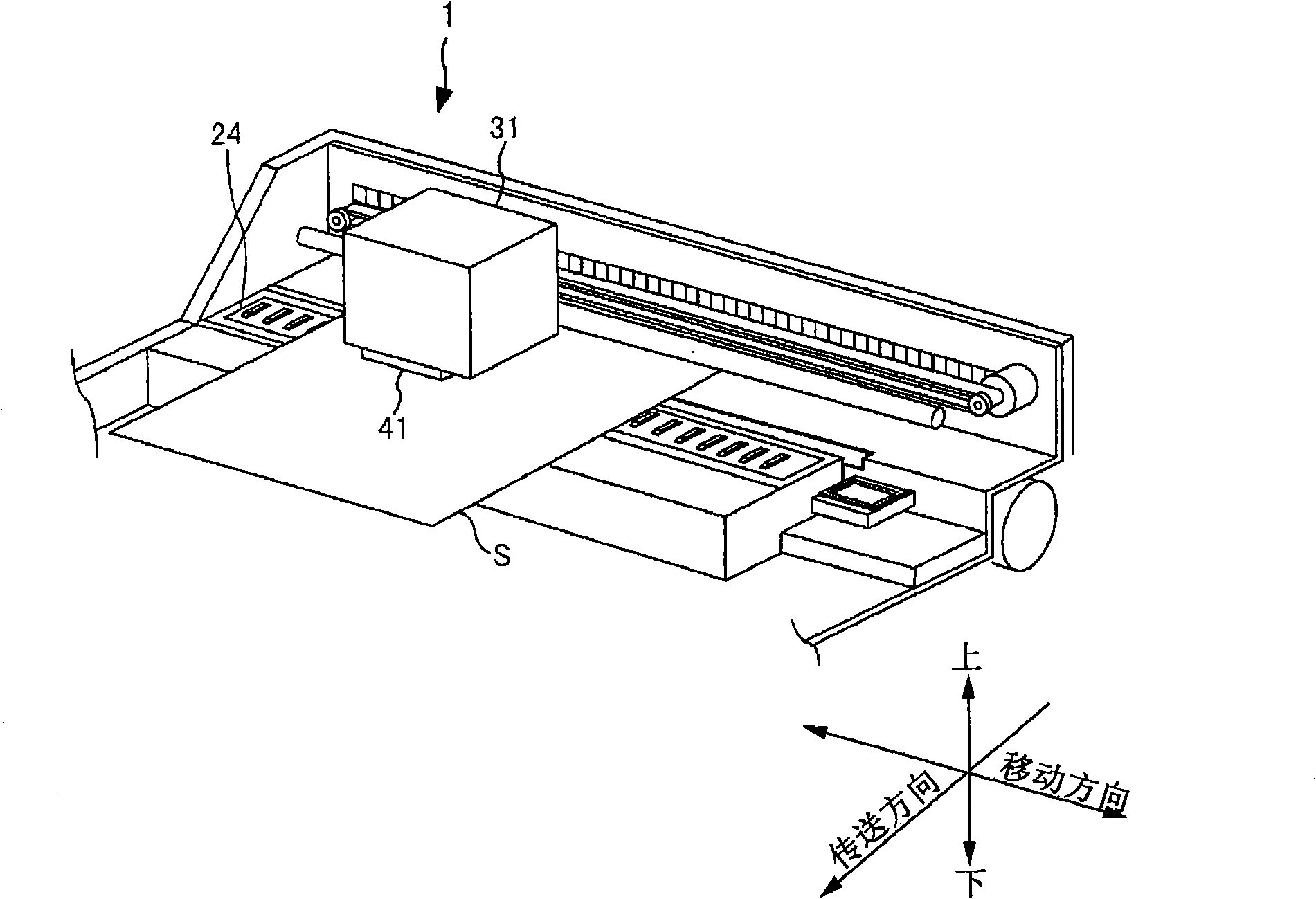

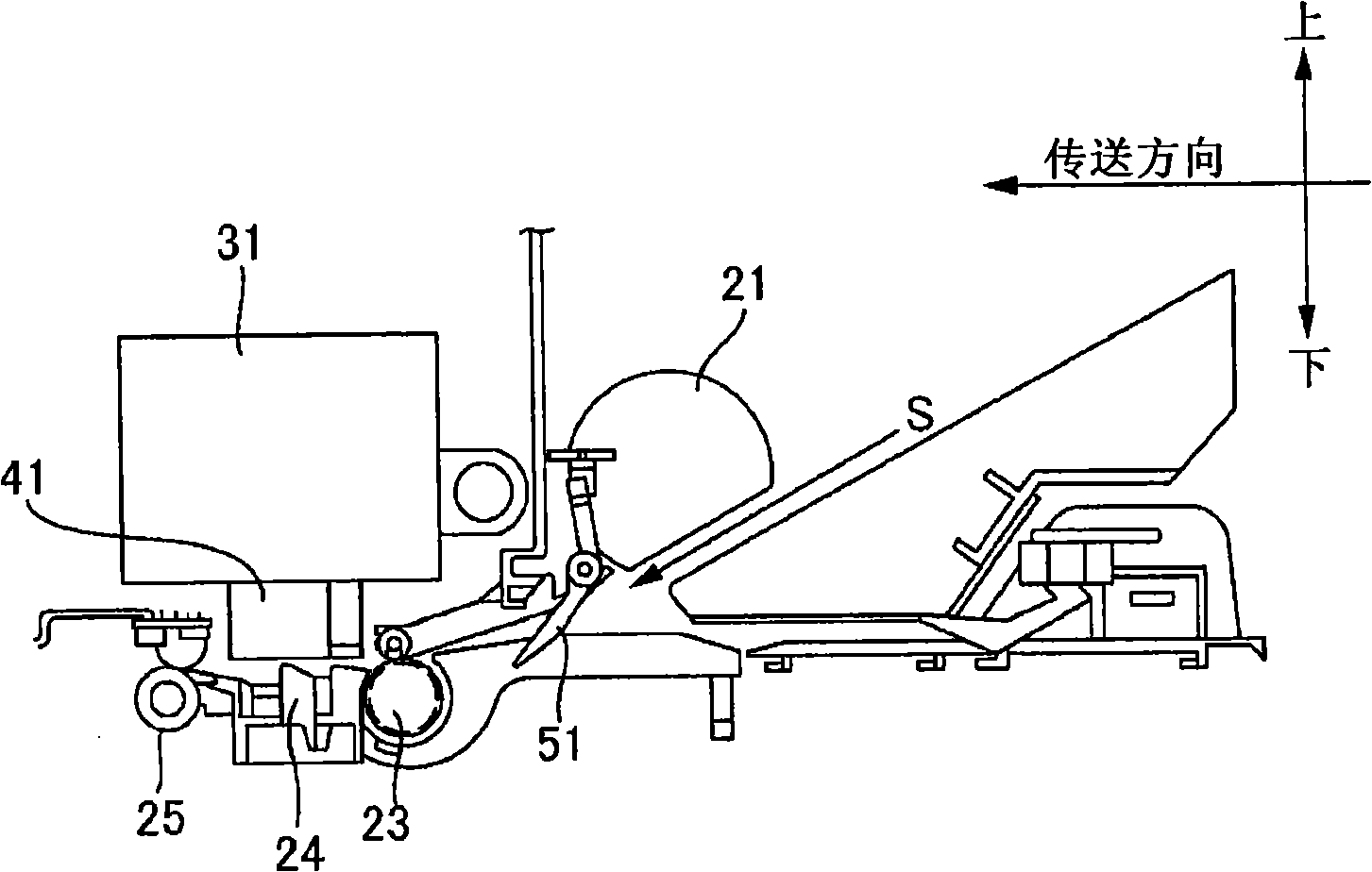

Method used

Image

Examples

Embodiment 2

[0113] Figure 12 It is the flow of the standby operation in Embodiment 2, Figure 13 It is a condition table of the standby operation of the second embodiment. In Embodiment 2, it is determined whether or not the drive signal generation circuit 70 executes the standby operation based on the head temperature Th and the transistor temperature Tt, and the standby time is determined.

[0114] First, when the controller 10 receives a printing command (S101), it detects the head temperature Th (S102), and detects the transistor temperature Tt (S103). Depending on the head temperature Th and the transistor temperature Tt, from Figure 13 Determine whether to execute the standby action and determine the standby time in the condition table. In addition, in the second embodiment, the standby operation is performed not for each path but for each page as in the first embodiment. When the standby operation is necessary (S104→YES / S105→NO), printing is executed after waiting for the gen...

Embodiment 3

[0122] Figure 14 This is the flow of the standby operation in the third embodiment. Figure 15A is the standby condition table of the head temperature Th corresponding to the standby action, Figure 15B is the standby condition table of the transistor temperature Tt. In the present embodiment 3, the standby time required to prevent discharge failure in the head 41 (hereinafter referred to as the first standby time T1) is determined based on the head temperature Th, and the required time to prevent the transistor from being destroyed is determined based on the transistor temperature Tt. The standby time (hereinafter referred to as the second standby time T2). Then, the first waiting time T1 (corresponding to the first waiting time) is compared with the second waiting time T2 (corresponding to the second waiting time T), and the generation of the drive signal for ink ejection is waited for longer.

[0123] First, after the printer driver receives a print command (S201), the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com