Gas turbine combustor

A technology of gas turbine and burner, applied in the direction of burner, burner, burner cooling, etc., can solve the problems of excessive temperature rise and reduce the reliability of gas turbine burner, and achieve the goal of suppressing excessive temperature rise and ensuring reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0045] (structure)

[0046] 1. Complete set of gas turbine equipment

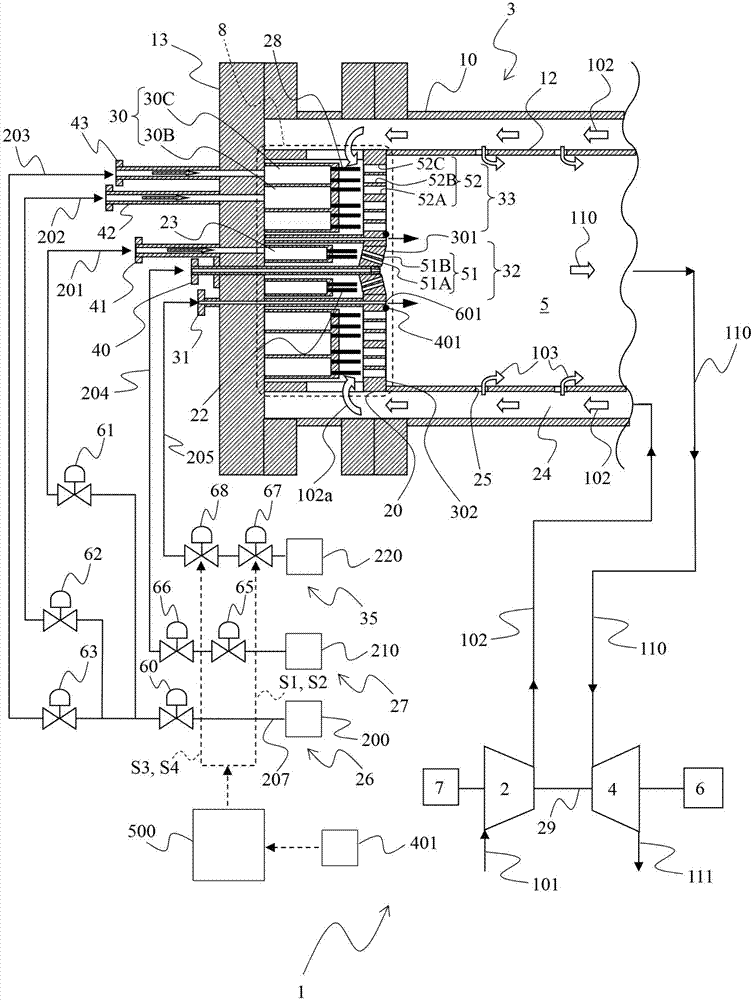

[0047] figure 1 A configuration example of a gas turbine plant to which a gas turbine combustor (hereinafter referred to as a combustor) according to the present embodiment is applied is shown. Such as figure 1 As shown, the gas turbine plant 1 includes a compressor (air compressor) 2 , a combustor 3 , a turbine 4 , a generator 6 , and a starter motor 7 .

[0048] The compressor 2 is started by the starting motor 7 , compresses the air 101 sucked from the atmosphere through an air intake unit (not shown), generates high-pressure compressed air 102 , and supplies it to the combustor 3 . The combustor 3 mixes and burns the compressed air 102 supplied from the compressor 2 and the fuel supplied from the fuel system 26 (described later), generates high-temperature combustion gas 110 , and supplies it to the turbine 4 . The turbine 4 is driven by the expansion of the combustion gas 110 supplied from the comb...

no. 2 approach

[0103] (structure)

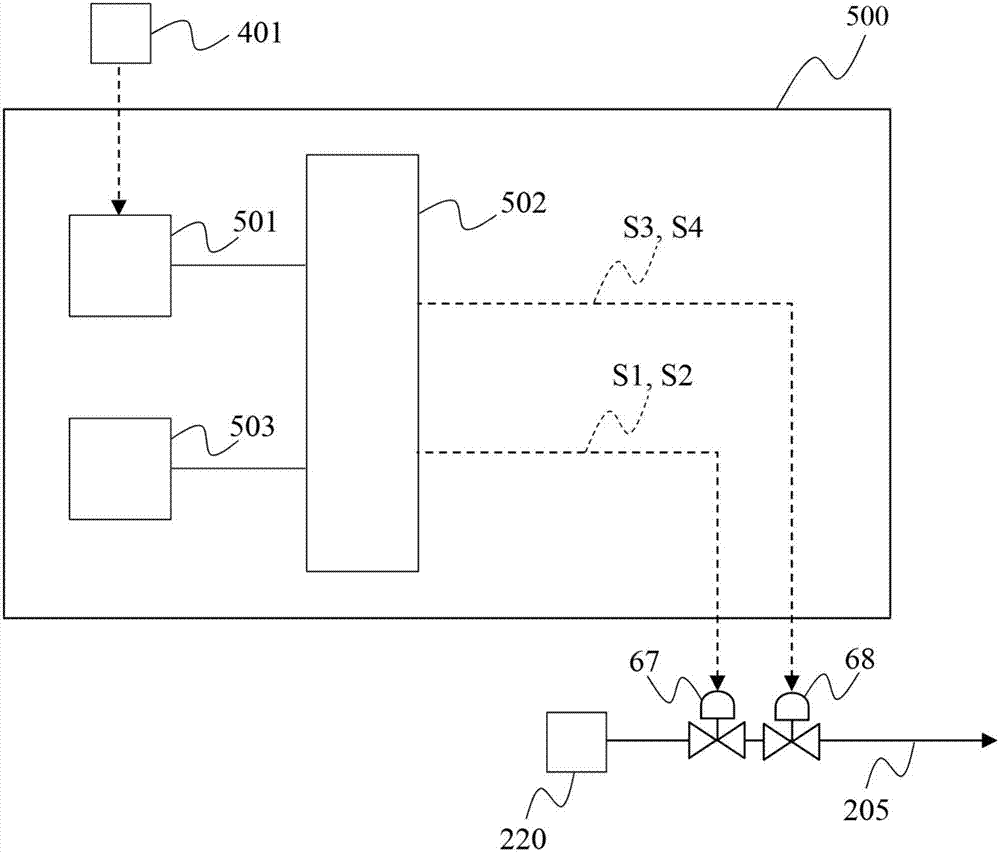

[0104] Figure 9 A structural example of a gas turbine plant to which the combustor according to the present embodiment is applied is shown. exist Figure 9 In , the same reference numerals are assigned to the same parts as those in the first embodiment described above, and explanations thereof are appropriately omitted.

[0105] In this embodiment, the cooling system 35 is different from the first embodiment in that it further includes a cooling pipe 206 , a cooling nozzle 34 , a thermocouple 402 , and a cooling hole 602 . Other points are the same as the first embodiment.

[0106] Such as Figure 9 As shown, the cooling pipe 206 branches from the cooling pipe 205 and connects the coolant supply source 220 and the cooling nozzle 34 . The cooling nozzle 34 is connected to the cooling hole 602 . The coolant introduced from the coolant supply source 220 to the cooling nozzle 34 via the cooling pipe 206 is injected into the combustion chamber 5 via the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com