Device for repairing a drill pipe

A technology of drill pipe and temperature control device, which is applied in the field of welding and surfacing, and can solve the problems that affect the surfacing of heavy workpieces, improve the convenience of operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

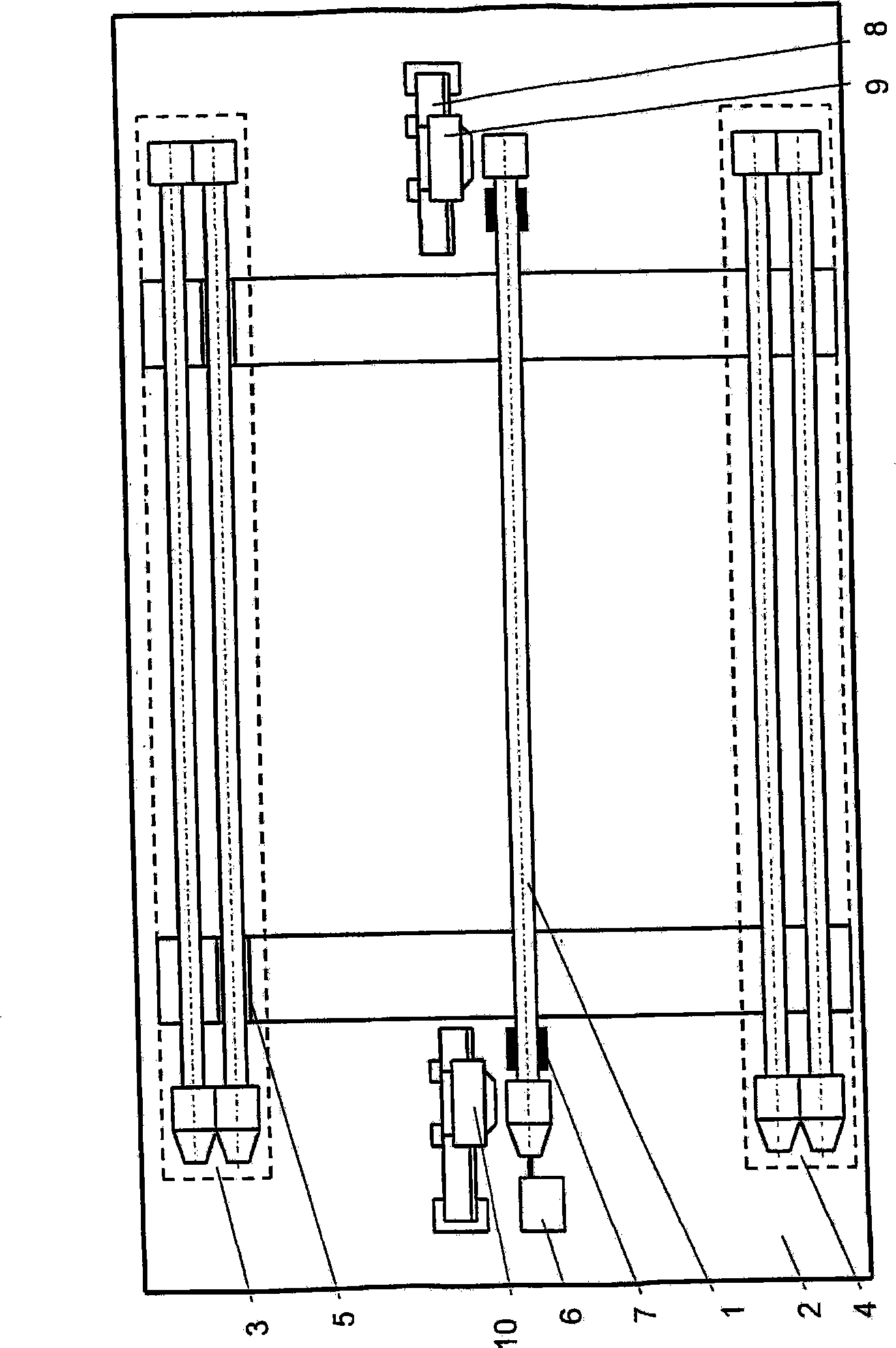

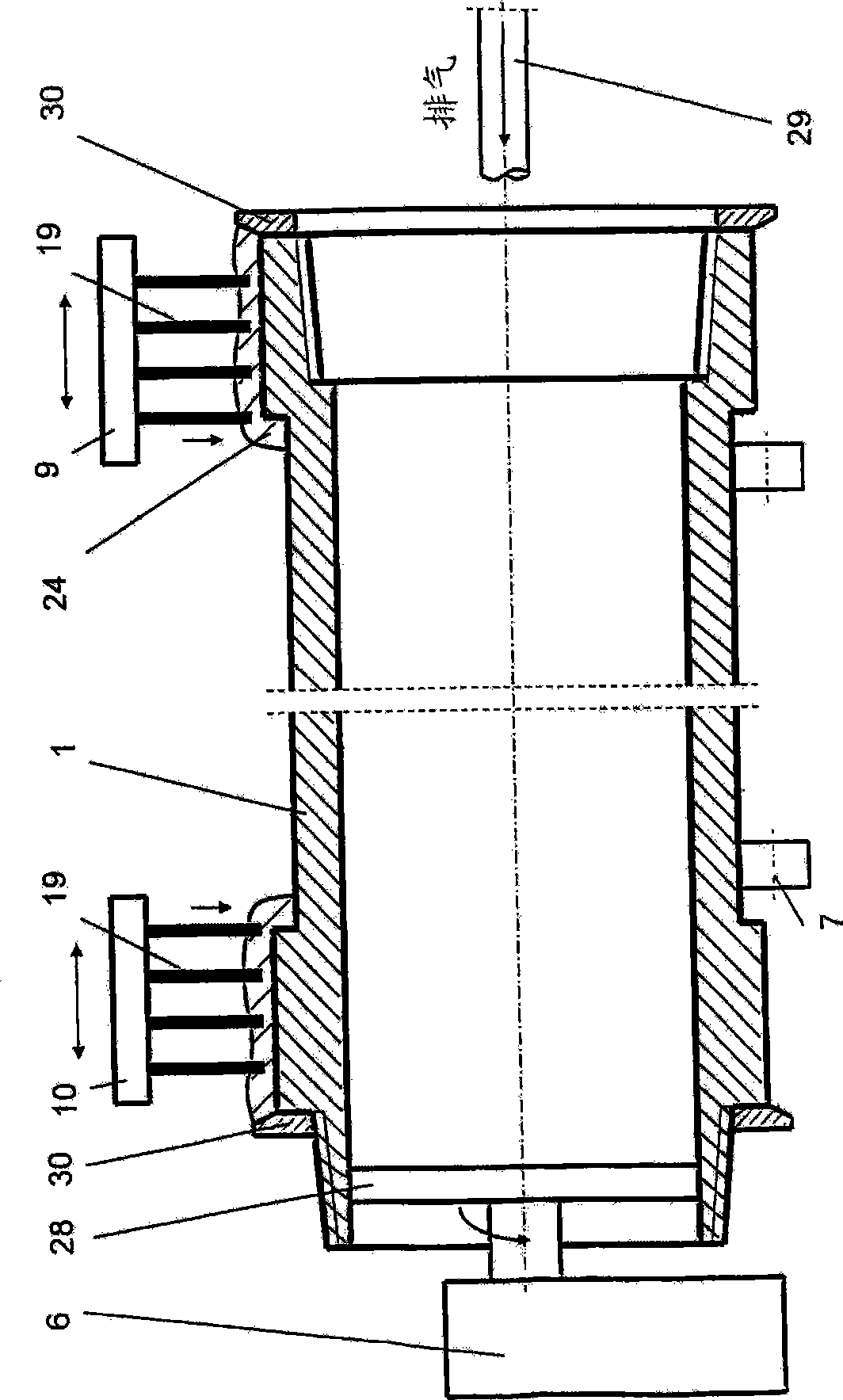

[0014] A device for repairing a drill pipe 1 includes a base plate 2, a pipe storage place 3, a finished product storage place 4, a drill pipe support 5, a drill pipe rotor 6, a rolling support 7, a self-propelled trolley 8 and a drill pipe for overlay welding The device for the sleeve part 9 of 1 and the device for surfacing the joint part 10 of the drill pipe 1.

[0015] When the positive pole ("+") is connected to the drill pipe and the negative pole ("-") is connected to the welding rod, the rolling bearing 7 of the drill pipe is supplied with current, and is equipped with a copper graphite brush 11 and a soft wire 12 .

[0016] The device for the sleeve and joint portion of surfacing drill pipe 1 is made up of guide rail 13 and automatic surfacing welding machine 14, and automatic surfacing welding machine 14 comprises the power source 15 with control panel 16, welding head 17, feeds welding electrode 19 The mechanism 18 of the welding rod 19, the mechanism 20 of the wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com