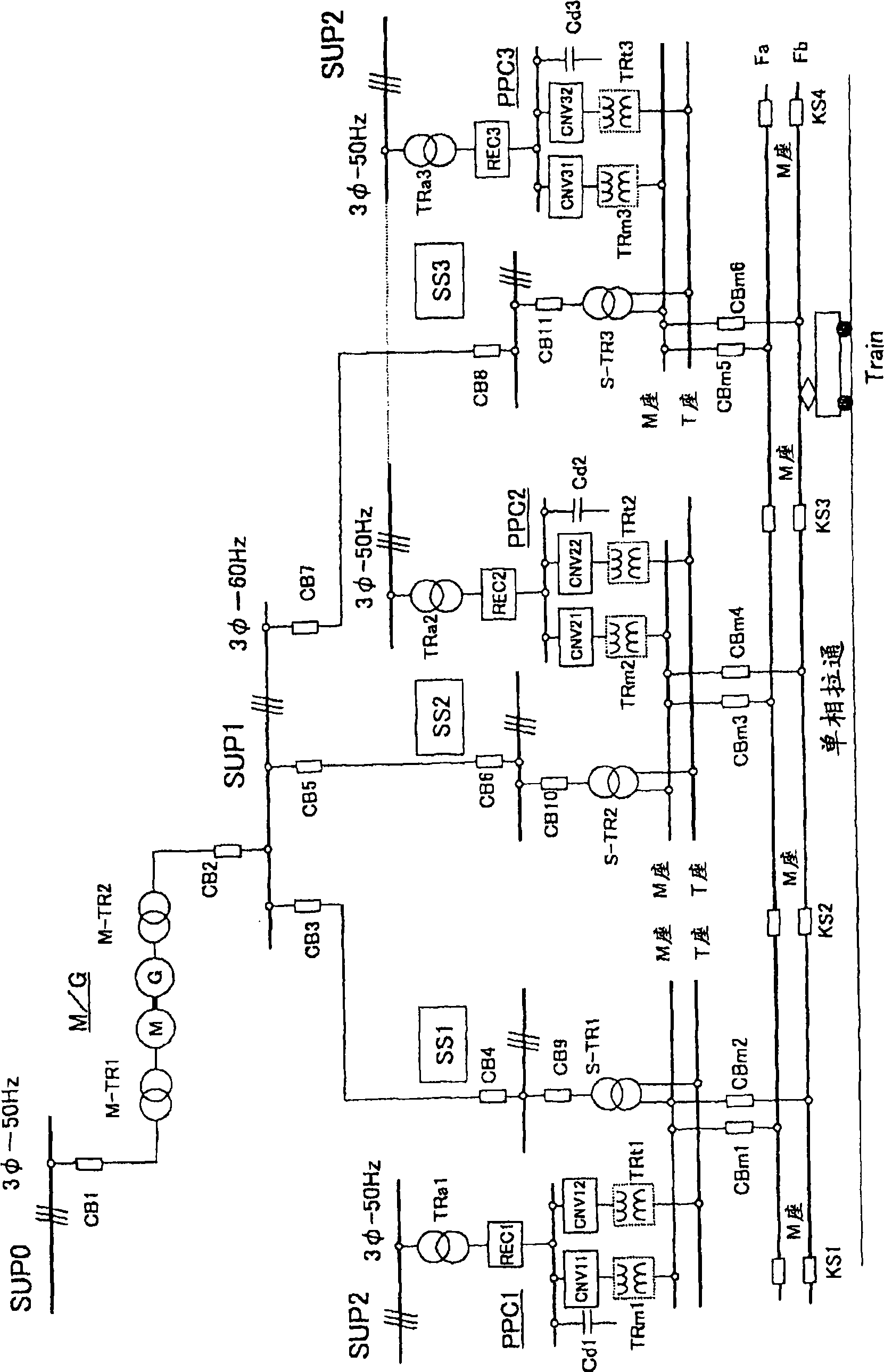

Electric railway alternating current feeding system

An electrified railway, AC feeding technology, applied in power lines, vehicle parts, transportation and packaging, etc., can solve the problems of inability to connect single-phase AC, difficulties in train public interests, time constraints, etc., to simplify tram control, The effect of improving riding mood and simplifying control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

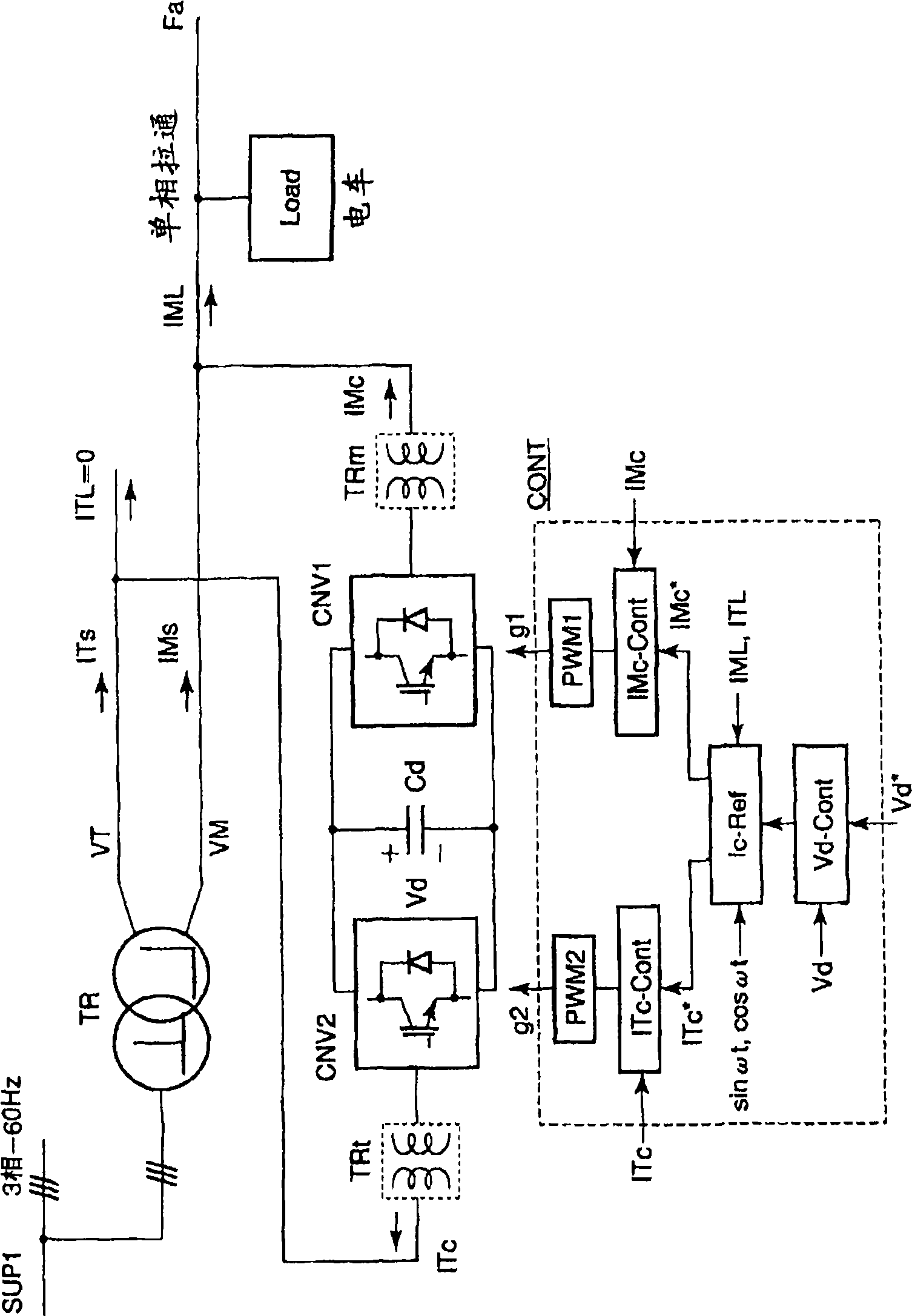

[0112] figure 2 It is a block diagram showing the first embodiment of the electric railway AC power feed system of the present invention. In the figure, SUP1 represents a three-phase AC power supply, TR represents a Scott-connected transformer, Fa represents a single-phase AC feeder, Load represents a trolley load, TRm, TRt represent a single-phase transformer, CNV1, CNV2 represent a voltage-type self-excited power conversion Cd represents a DC smoothing capacitor, and CONT1 represents a control unit that balances the aforementioned two-phase unbalanced compensation currents (compensation current detection values) IMc, ITc output through the power converters CNV1, CNV2 and single-phase transformers TRm, TRt. The compensation currents IMc and ITc, like the Hall CT not shown, are provided by arranging current detectors in, for example, figure 2 The position of the arrow can be detected.

[0113] The Scott wiring transformer TR transforms the three-phase AC power sources Vu, Vv, a...

no. 2 Embodiment approach

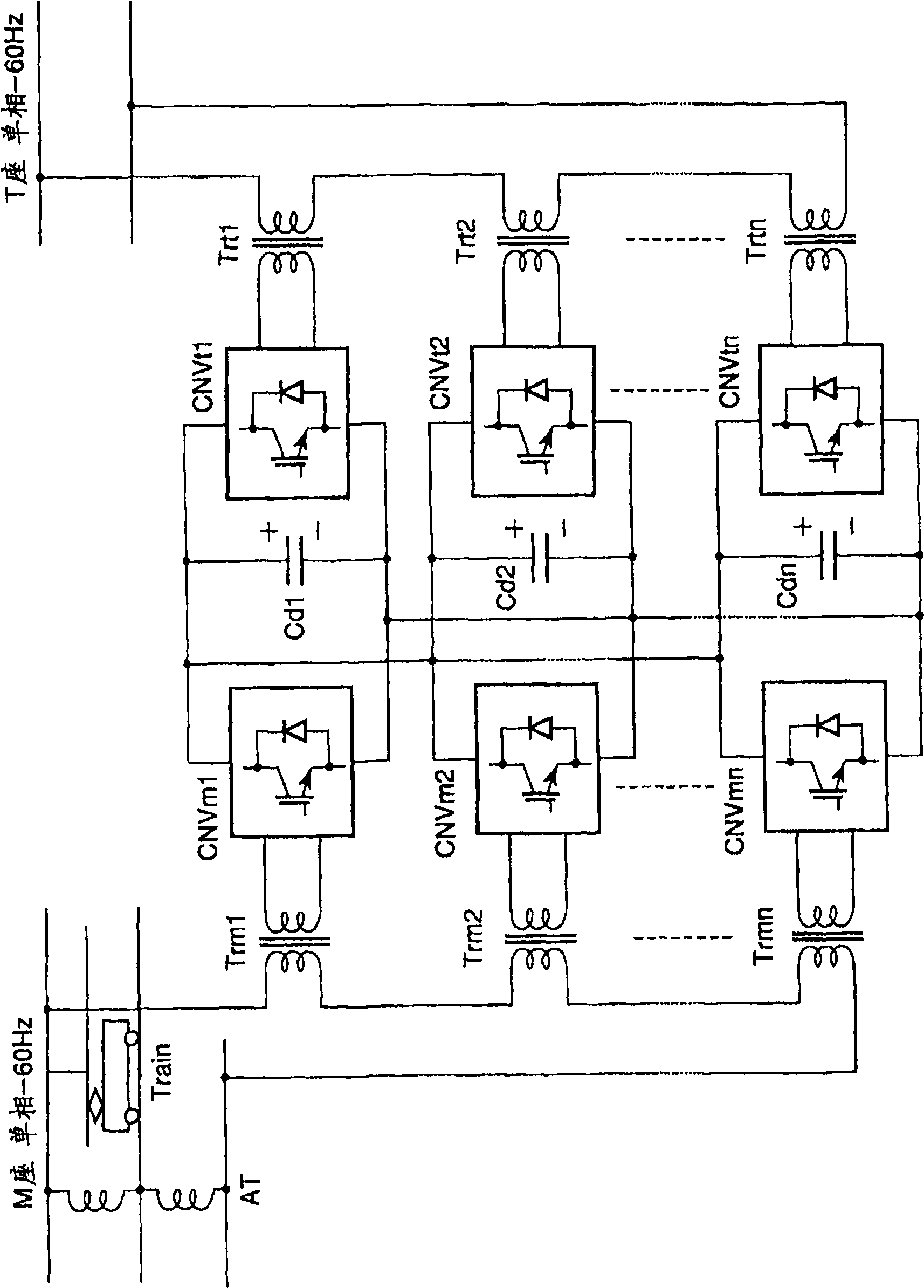

[0163] Picture 10 It is a block diagram showing an electric railway AC power feed system according to the second embodiment of the present invention.

[0164]In the figure, SUP1 represents a three-phase AC power supply, TR represents a Scott-connected transformer, Fa represents a single-phase AC feeder, Load represents a trolley load, TRm, TRt represent a single-phase transformer, CNV1, CNV2 represent a voltage-type self-excited power conversion Cd represents a DC smoothing capacitor, Lf and Cf represent reactors and capacitors constituting the LC filter, and CONT1 represents a control unit for the compensation currents IMc and ITc output by the above-mentioned power converters CNV1 and CNV2.

[0165] The Scott wiring transformer TR transforms the three-phase AC power sources Vu, Vv, and Vw into two-phase AC voltages VM and VT, and the two-phase voltage VM and VT have a phase difference of 90°.

[0166] The output of Block M is connected to the single-phase AC feeder Fa, Block T...

no. 3 Embodiment approach

[0199] Picture 12 It is a block diagram showing the third embodiment of the control unit of the compensation currents IMc and ITc output from the first and second self-excited power converters CNV1 and CNV2 of the AC feed system of the present invention.

[0200] In the figure, Kff represents a proportional element, C1~C3 represent a comparator, Gv(S) represents a voltage control compensation circuit, M1, M2 represent a multiplier, AD1~AD5 represent an adder and subtractor, Gi1(S), Gi2(S) Represents the current control compensation circuit, PWM1 and PWM2 are pulse width modulation control circuits.

[0201] The power PL of the single-phase load Load fluctuates at a frequency twice the frequency f1 of the AC feeder line. The detected value of the load power PL is time-averaged, and the average value PL(av) of the load power is obtained. Next, through the proportional element Kff, a forward-compensated effective current peak value command Ismff proportional to the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com