Robot for mounting anti-detour lightning lightning rod on high-tension line

An anti-shielding and lightning rod technology, applied in the field of robots, can solve the problems of reduced strength, corrosion and aging of lightning wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

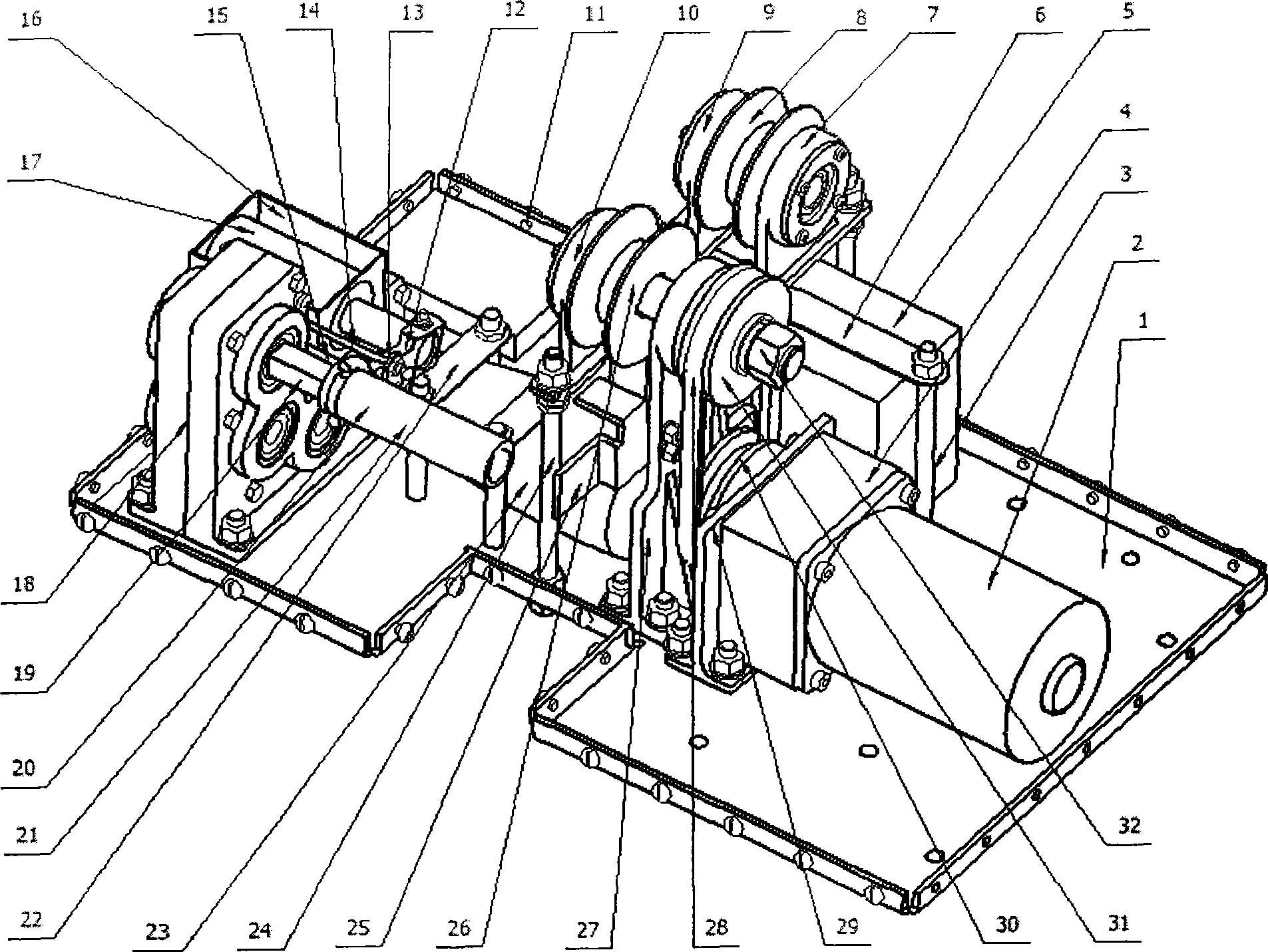

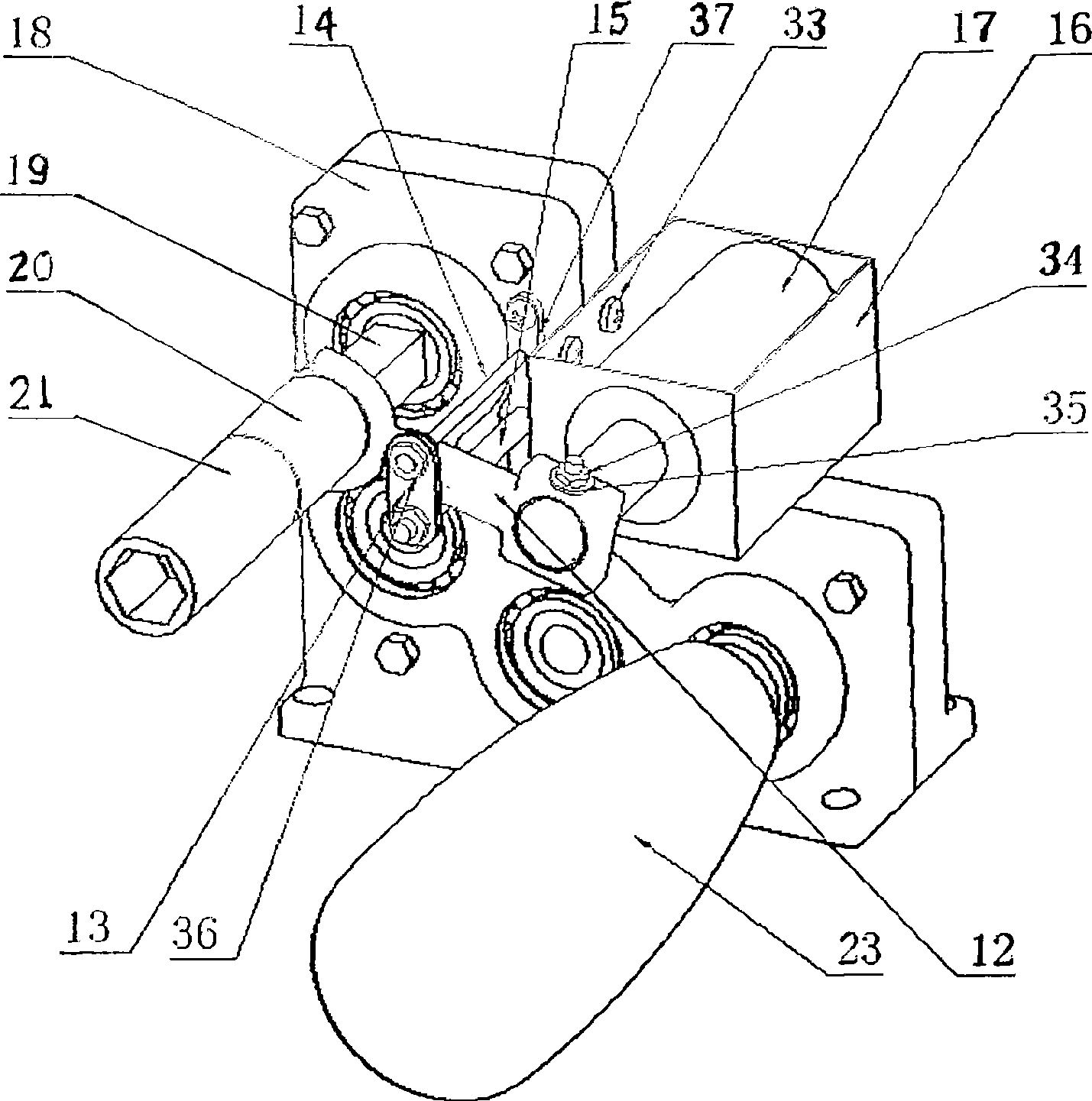

[0021] refer to figure 1 , 2 , 3. The present invention consists of a chassis, a traveling mechanism A, a flexible working mechanism B and a wireless control system C. The case cover is connected with the base plate 1 by screws 11 to form a case. The traveling mechanism A, the flexible working mechanism B and the wireless control system C are installed in the case, which can effectively prevent the main parts from being damaged by external force. The battery pressure strip 6 is fixed on the bottom plate 1 by fixing bolts 3 . The electromagnet 17 is installed on the electromagnet mounting base 16, and the electromagnet mounting base 16 is installed on the gear box 18 through the screw 33. The motor 2 is mounted on the base plate 1 through a motor base 29 . The case cover and the base plate are connected by connecting screws 11.

[0022] The battery 5 of the running mechanism A drives the motor 2, and the motor 2 drives the driving wheel 26 and the balance wheel 8 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com