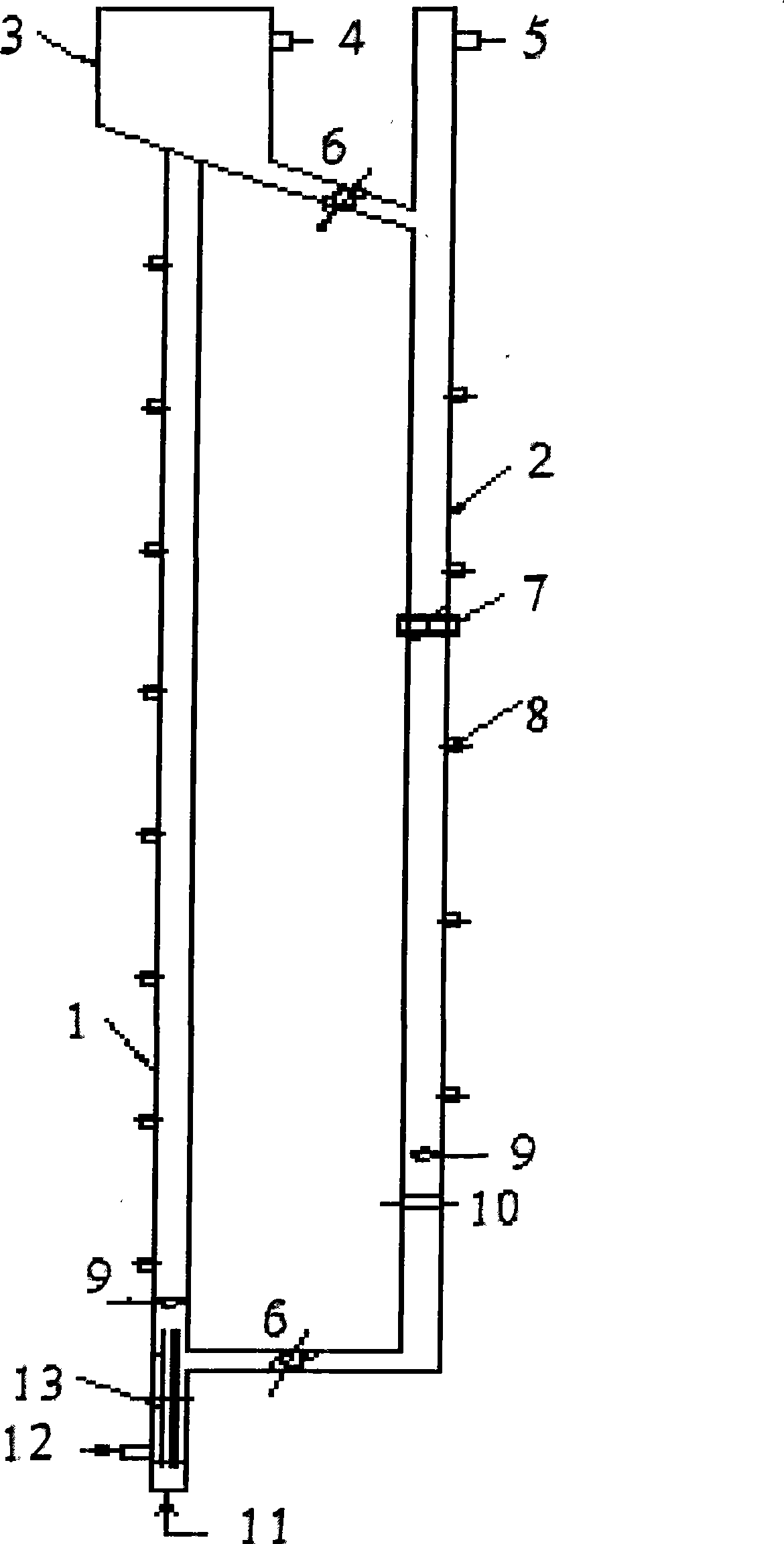

Gas-liquid-solid circulating fluidized bed adsorptive separation device and operation method

A circulating fluidized bed, adsorption separation technology, applied in solid adsorbent liquid separation, separation method, separation by moving adsorbent, etc. The effect of mass transfer and desorption mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

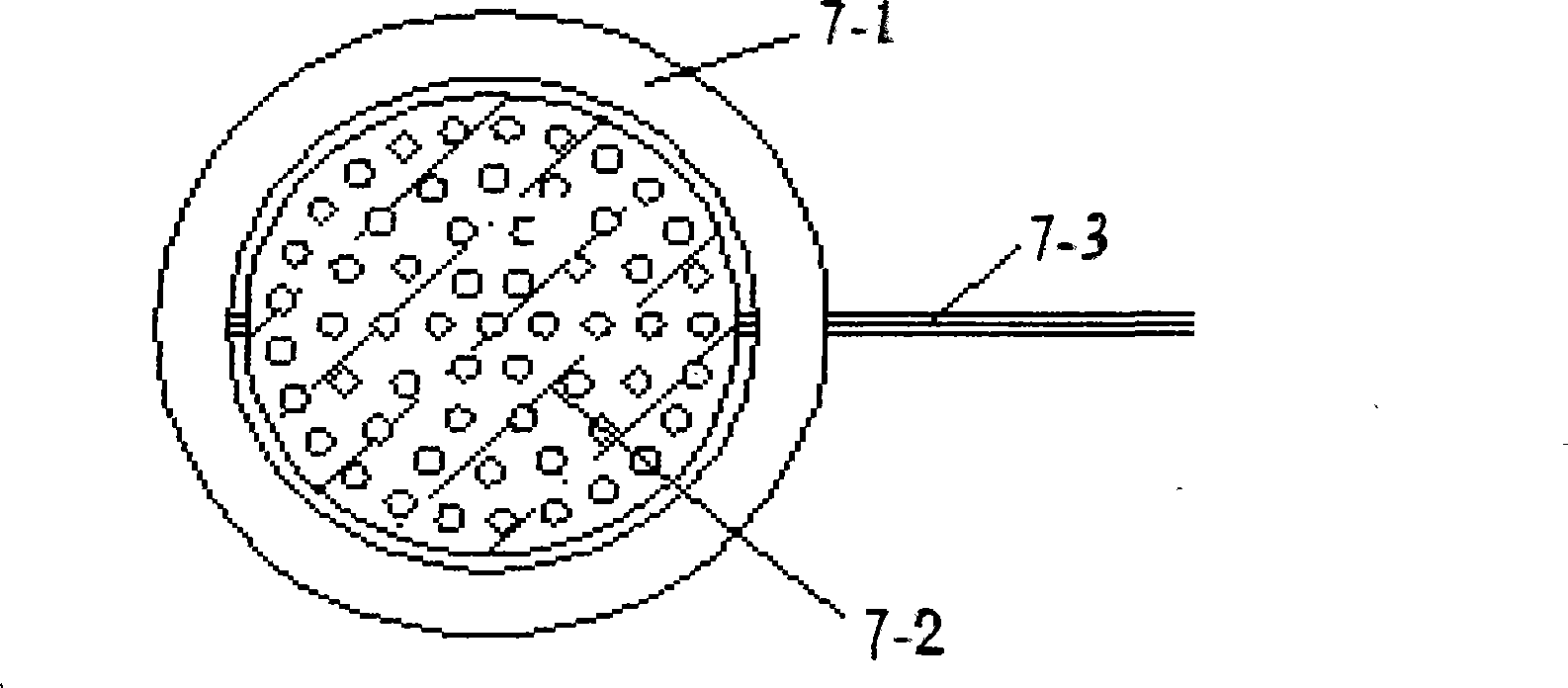

Method used

Image

Examples

Embodiment approach 1

[0037] (1) Use water for debugging, add adsorption resin particles D-101 from the upper part of the descending bed 2, pass gas into the ascending bed 1 through the gas distributor 9, adjust the flow meter, and keep the gas volume at 0.0001-5.0m 3 / s, and make the system reach a steady cycle flow state.

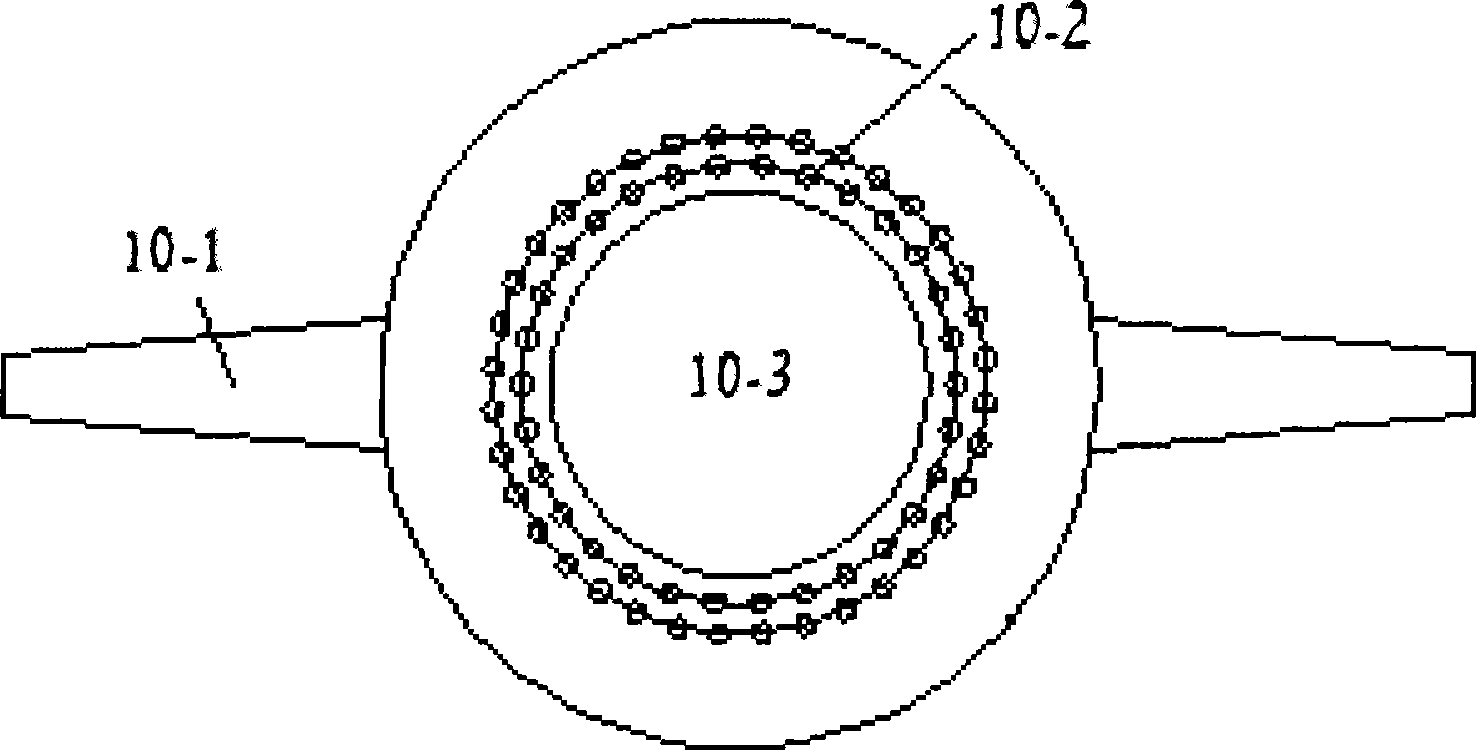

[0038] (2) Use a pump to add matrine extract to the descending bed 2 through the extract distributor 10, the feed rate is 0.001-1m / s, and simultaneously use a pump to pass 60-80% ethanol into the ascending bed 1 for eluting The eluent passes through the main and auxiliary eluent distributor 13 to form two main and auxiliary liquid flows with a flow rate of 0.001-1m / s.

[0039] (3) The extract moves upward after entering the descending bed 2, and contacts and adsorbs in countercurrent with the adsorbing resin particles moving downward continuously. The extract that reaches the top of the down-bed has undergone relatively sufficient adsorption and separation, and will be discha...

Embodiment approach 2

[0044] (1) Use water for debugging, add adsorption resin particles CDA-40 from the upper part of the down bed 2, pass gas into the down bed 2 through the gas distributor 9, adjust the flow meter, and keep the gas volume at 0.0001-5.0m 3 / s, and make the system reach a steady cycle flow state.

[0045] (2) Utilize the pump to add the baicalin extract in the down-going bed 2 through the extract distributor 10, the feeding speed is 0.001-1m / s, and simultaneously use the pump to pass 60-80% ethanol eluent into the up-going bed 1 , the eluent passes through the main and auxiliary eluent distributor 13 to form two main and auxiliary liquid flows with a flow rate of 0.001-1 m / s.

[0046] (3) After the extraction liquid enters the descending bed 2, it moves upward together with the added gas, and contacts and adsorbs with the adsorption resin particles moving downward continuously, and the disturbance generated by the added gas in the descending bed reduces the thickness of the liquid...

Embodiment approach 3

[0051] (1) Use water for debugging, add adsorption resin particles ADS-F8 from the upper part of the descending bed 2, and pass gas into the ascending bed 1 and descending bed 2 respectively through two gas distributors 9, and adjust each flowmeter to maintain Gas volume is 0.0001-5.0m 3 / s, and make the system reach a steady cycle flow state.

[0052] (2) Utilize the pump to add the ginkgo extract in the descending bed 2 through the extract distributor 10, the feeding speed is 0.001-1m / s, and utilize the pump to pass into the 60-80% ethanol eluent in the ascending bed 1 simultaneously, The eluent passes through the main and auxiliary eluent distributors 13 to form two main and auxiliary streams with a flow velocity of 0.001-1 m / s.

[0053] (3) After the extraction liquid enters the descending bed 2, it moves upward together with the added gas, and contacts and adsorbs with the adsorption resin particles moving downward continuously, and the disturbance generated by the added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com