Sugarcane juice clarification method with intensified sulfitation-neutralization reaction

A technology of sulfur fumigation and reaction, applied in the fields of application, food preparation, food science, etc., can solve the problems of uneven particle size, pH fluctuation of cane juice, large residual amount, etc., and achieve solid precipitated particles, fast reaction speed, and good adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

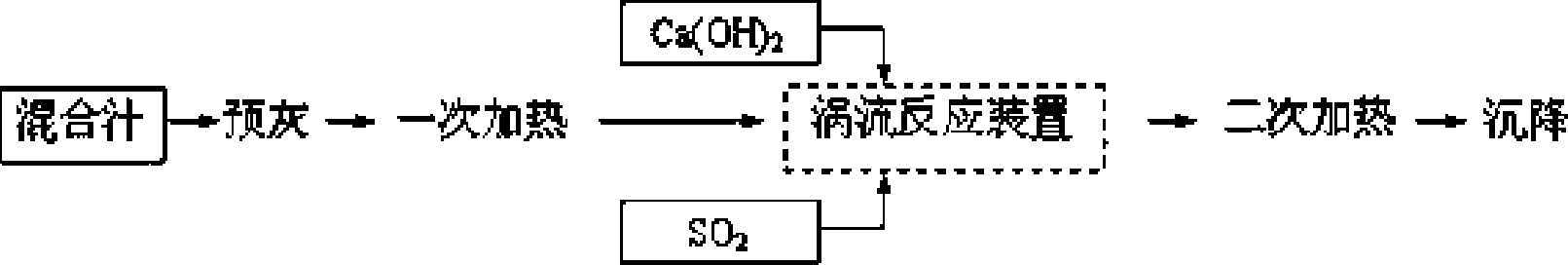

[0037] A kind of sugarcane juice clarification method (referring to figure 1 ), using the sulfurous acid clarification process, including pre-ashing, primary heating, sulfur fumigation neutralization, secondary heating and settling processes, the sulfur fumigation neutralization process includes a process of passing sugarcane juice into a vortex reaction device for reaction Strengthening the sulfur fumigation neutralization reaction step, the described strengthening sulfur fumigation neutralization reaction step is carried out in conjunction with the sulfur fumigation neutralization process, it is to pass the mixed cane juice after pre-ashing and primary heating into the vortex reaction device, and the lime Milk (Ca(OH) 2 ) and SO 2 A vortex reaction device is also added at the same time, and the sulfur fumigation neutralization reaction is strengthened in the vortex reaction device. The sugarcane juice after the sulfur fumigation neutralization reaction enters the secondary ...

Embodiment 2

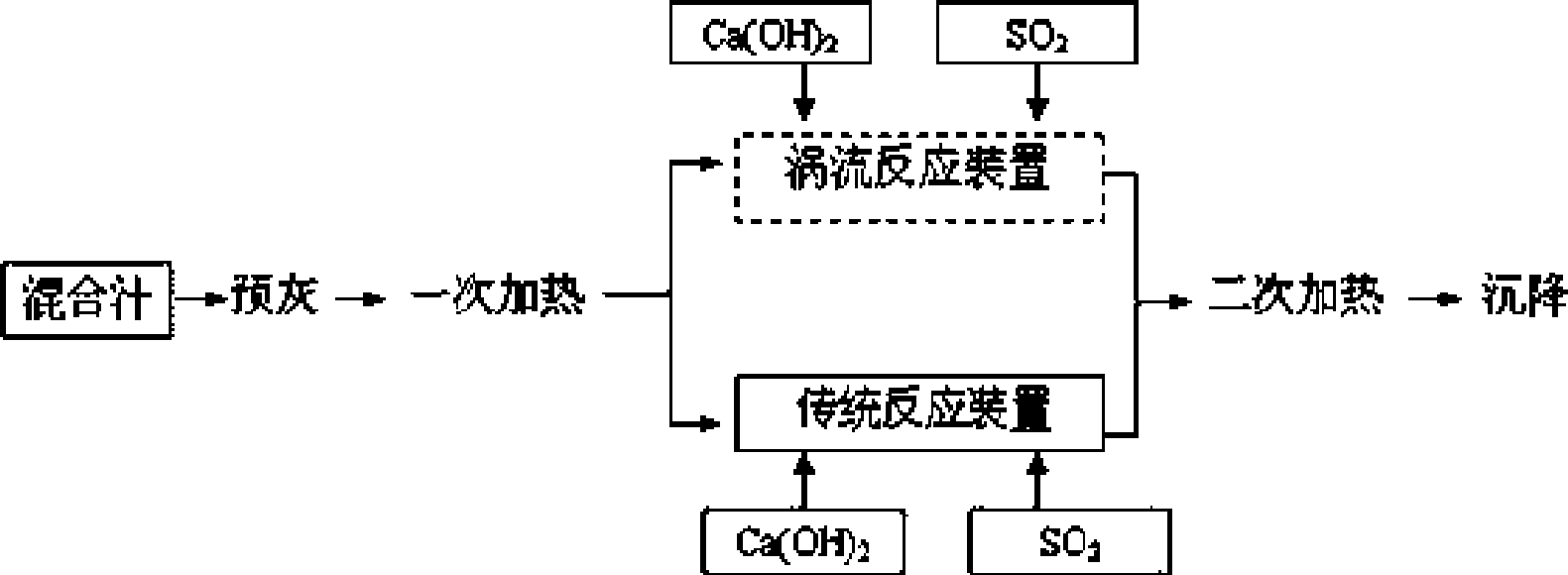

[0039] A kind of sugarcane juice clarification method (referring to figure 2 ), using the sulfurous acid clarification process, including conventional pre-ash, primary heating, sulfur fumigation neutralization, secondary heating and settling processes, the sulfur fumigation neutralization process also includes a cane juice is passed into the vortex reaction device The step of intensifying sulfur fumigation neutralization reaction for the reaction, the step of intensifying sulfur fumigation neutralization reaction is carried out in combination with the sulfur fumigation neutralization process, which is to pass the mixed sugarcane juice after pre-ashing and primary heating into the vortex reaction device, milk of lime (Ca(OH) 2 ) and SO 2 A vortex reaction device is also added at the same time, and the sulfur fumigation neutralization reaction is carried out in the vortex reaction device. The other part of the pre-ashed and once-heated cane juice is carried out by the traditio...

Embodiment 3

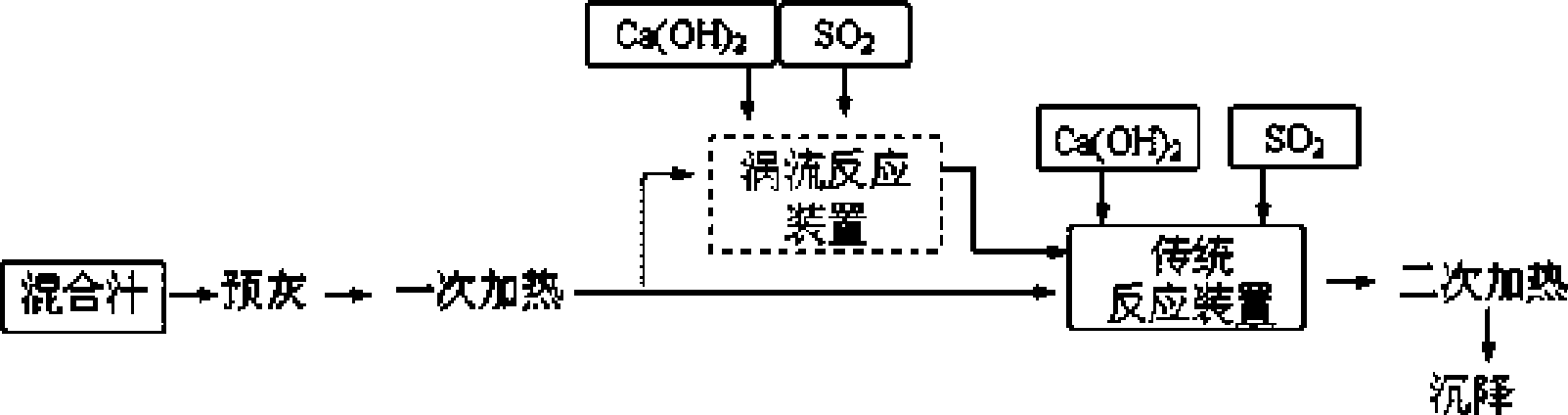

[0041] A kind of sugarcane juice clarification method (referring to Fig. 3) of strengthening sulfur fumigation neutralization reaction, adopts sulfurous acid clarification process, comprises conventional pre-ash, primary heating, sulfur fumigation neutralization, secondary heating and settling operation, described The sulfur fumigation neutralization process also includes an enhanced sulfur fumigation neutralization reaction step of passing sugarcane juice into a vortex reaction device for reaction. The enhanced sulfur fumigation neutralization reaction step is carried out in conjunction with the sulfur fumigation neutralization process. Ash, mixed cane juice after primary heating, partly passed into the vortex reaction device, milk of lime (Ca(OH) 2 ) and SO 2 Also add the vortex reaction device simultaneously, carry out intensified sulfur fumigation neutralization reaction in the vortex reaction device, after the sugarcane juice after this strengthened sulfur fumigation neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com