Manual and automatic control axial flow distribution reversing rotary valve

A flow distribution valve and flow distribution technology, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of normal production and operation, difficult balance of rotary valves, single control mode, etc., to achieve good sealing, flexible rotation, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

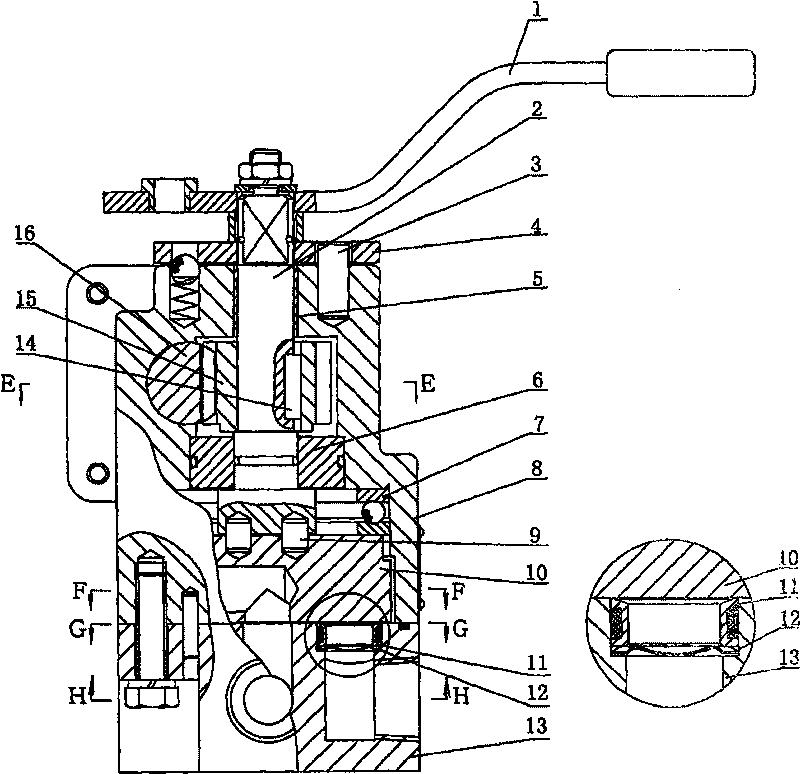

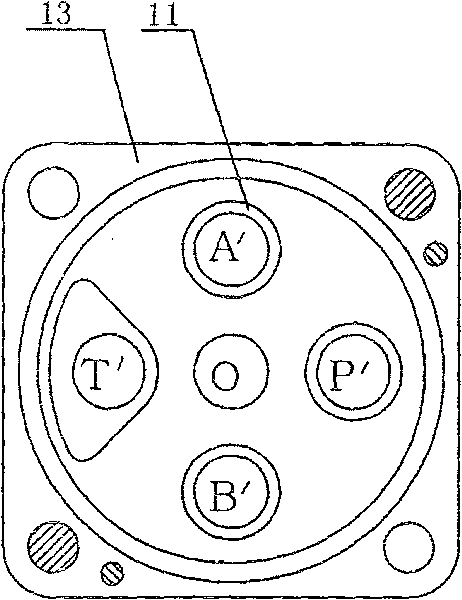

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

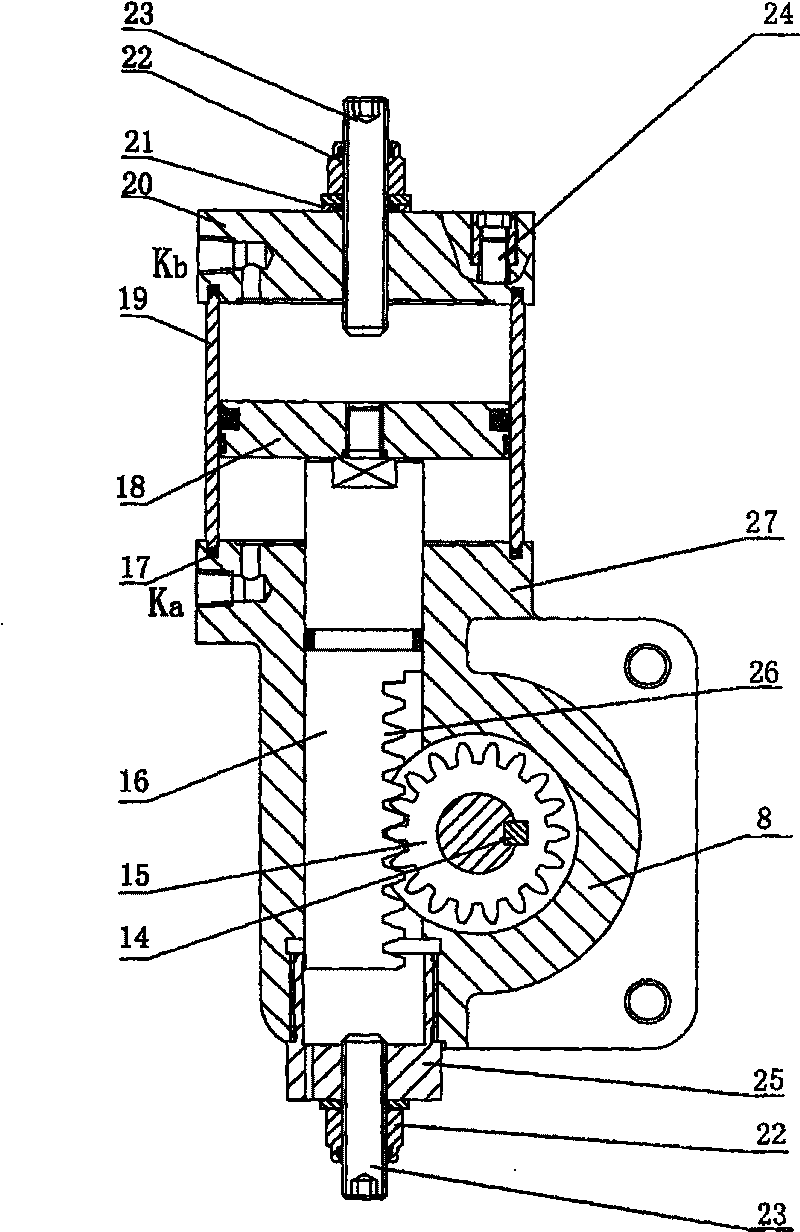

[0015] There is a screw hole in the middle of the cylinder head 20, and a sealing ring 21, a lock nut 22, and a stroke adjustment screw 23 are installed. There are mounting screw holes on the four opposite corners, a ring groove on the bottom surface, and an air intake or exhaust on the side wall. Hole Kb.

[0016] One side of the upper valve body 8 is a square flange 27. There is a guide hole in the middle of the square flange 27, and a ring groove is arranged on the edge. There is an eccentric distance between the guide hole and the vertical center hole of the upper valve body. The side wall of the square flange There are air intake or exhaust holes Ka.

[0017] There is a rack 26 on one side of the lower end of the piston rod 16, and the piston rod passes through the guide hole on the upper valve body 8 to mesh with the gear 15 on the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com