Quick-freeze food shop

A quick-frozen food and workshop technology, which is applied in the field of food workshops, can solve problems affecting food microbial detection indicators and hidden dangers in food safety documents, and achieve the effects of preventing mold growth, corrosion prevention, and convenient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

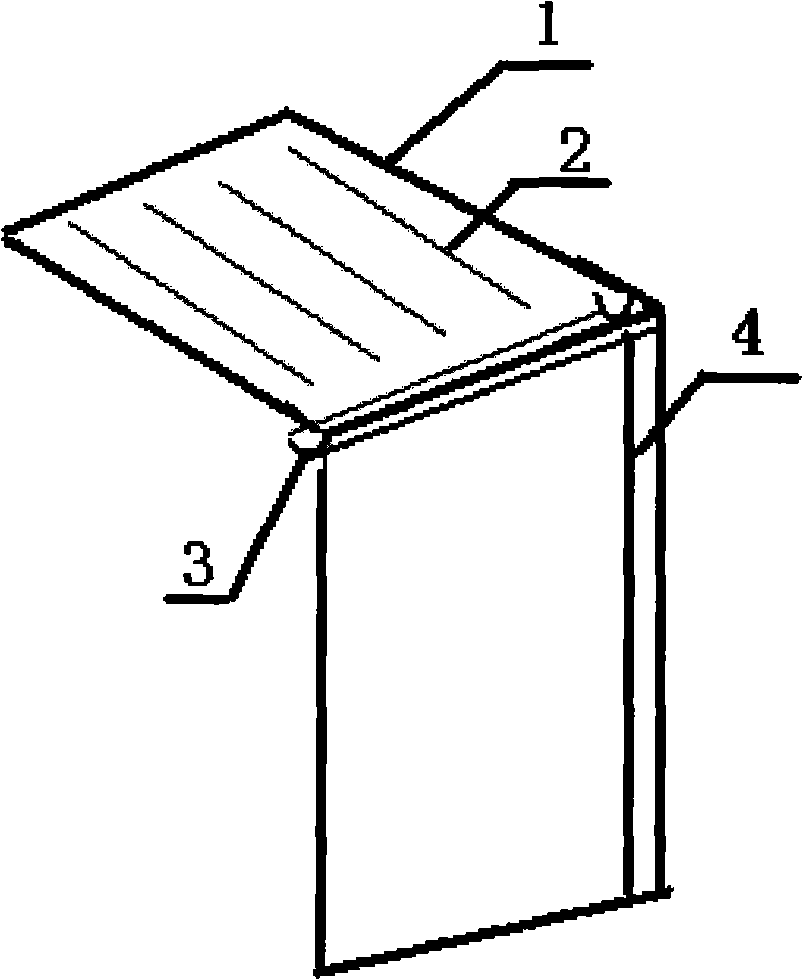

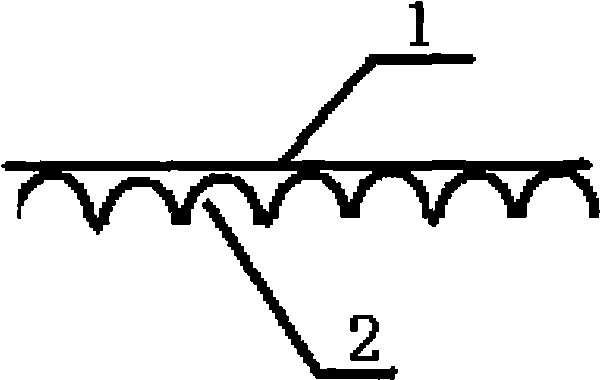

[0010] Below in conjunction with the accompanying drawings the present invention is further described: the ceiling 1 of the quick-freezing workshop is a slope shape with high middle ends and low ends, and the ceiling plate surface is provided with a plurality of arc-shaped diversion grooves 2, which are painted with hydrophobic paint. There is a water diversion groove 3 at the joint between the two ends of the wall and the wall. When the condensed water accumulated in the arc-shaped diversion groove 2 of the ceiling 1 reaches a certain amount, it will flow into the water diversion groove 3 along the diversion groove 2, and the water diversion groove 3 The end of is connected with drainpipe 4, and it drains water down and discharges.

[0011] Applying the present invention to the quick-freezing industry, the hydrophobic paint on the ceiling can prevent moisture from corroding the ceiling, and is convenient to dry, and guides the condensed water out to prevent the condensed water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com