Composite spark plug

An ignition device, engineering polymer technology, applied in the field of spark plugs, can solve the problem of reducing the temperature of the ground electrode, undeclared, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

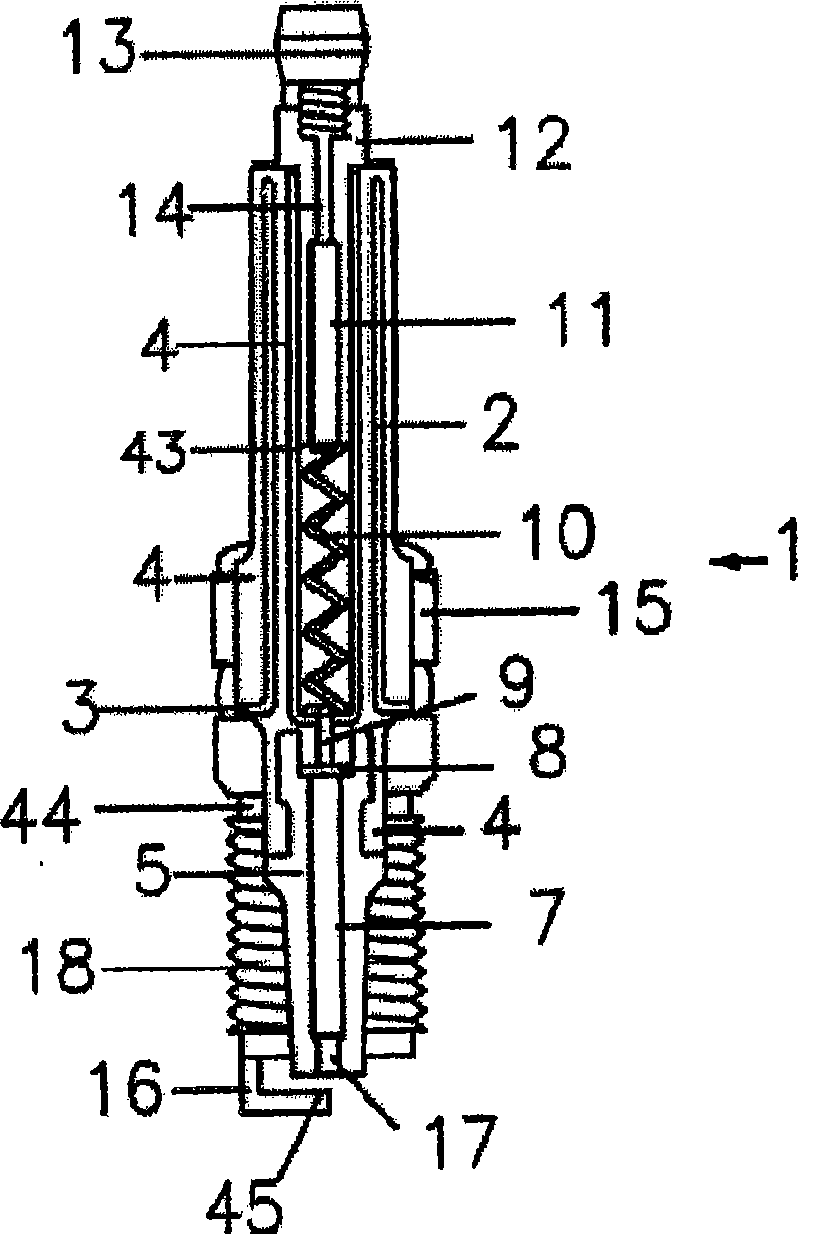

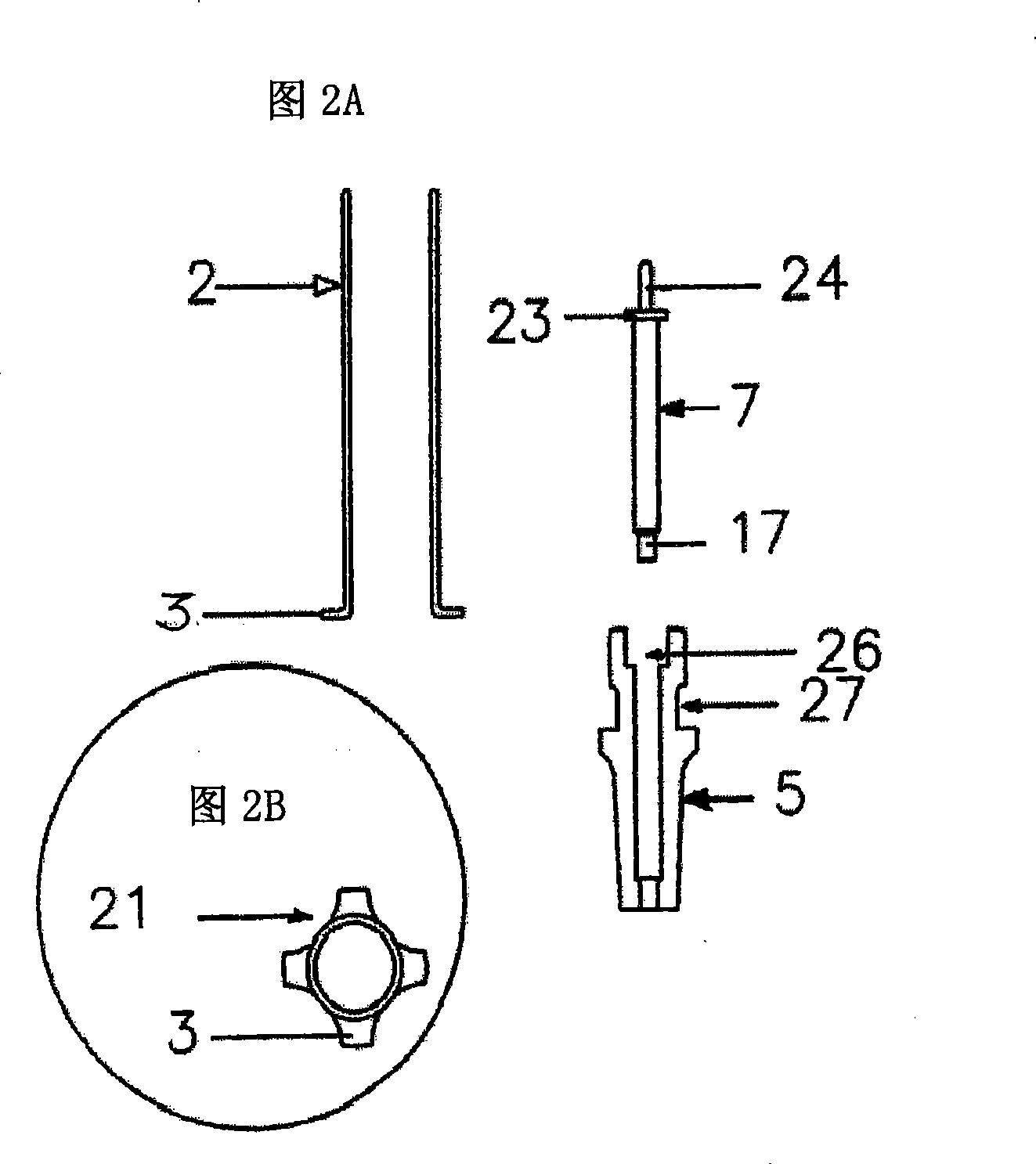

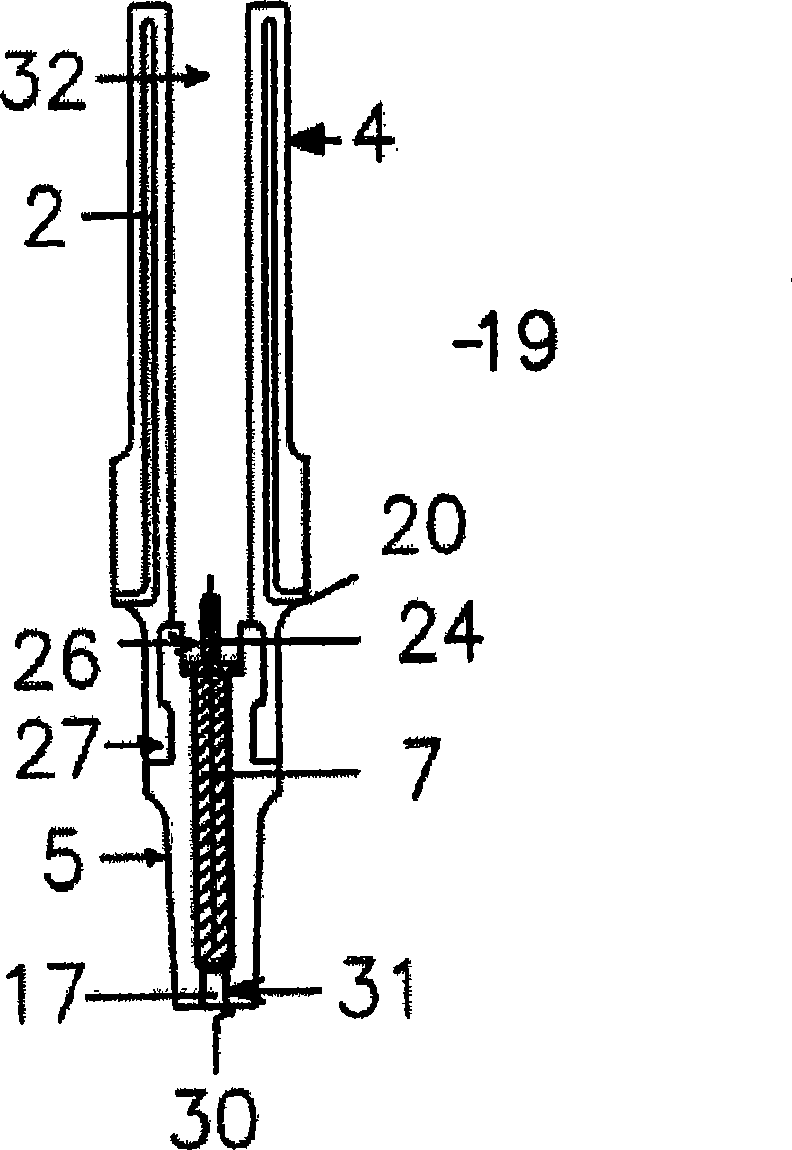

[0047] See now the accompanying drawings, especially figure 1 , the spark plug or ignition device used in the spark ignition internal combustion engine of the present invention is generally shown as 1 . The spark plug or ignition device 1 consists of a preferably metallic case or housing 15 having a generally cylindrical base 44 on which external threads 18 may be formed for use with a spark ignition internal combustion engine ( not shown) to the cylinder head (not shown). The cylindrical base 44 of the spark plug housing has a generally flat plane perpendicular to the longitudinal axis of the spark plug 1, on which plane the ground electrode 16 is attached, preferably by conventional welding methods. In one embodiment of the invention, the ground electrode 16 has a preferably rounded tip 45 of a Rhenium / Tungsten sintered compound, which prevents corrosion of the electrode 16 due to high power discharges, as further disclosed herein.

[0048]The spark plug or ignition devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com