Electric transformer winding and iron core fixing device

A technology for fixing power transformers and iron cores, which is applied in the directions of transformer/inductor cores, transformer/inductor coils/windings/connections, etc. Uneven force and other problems, to achieve the effect of reducing no-load current, improving no-load performance, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Now in conjunction with the accompanying drawings, the technical content of the present invention is described in detail.

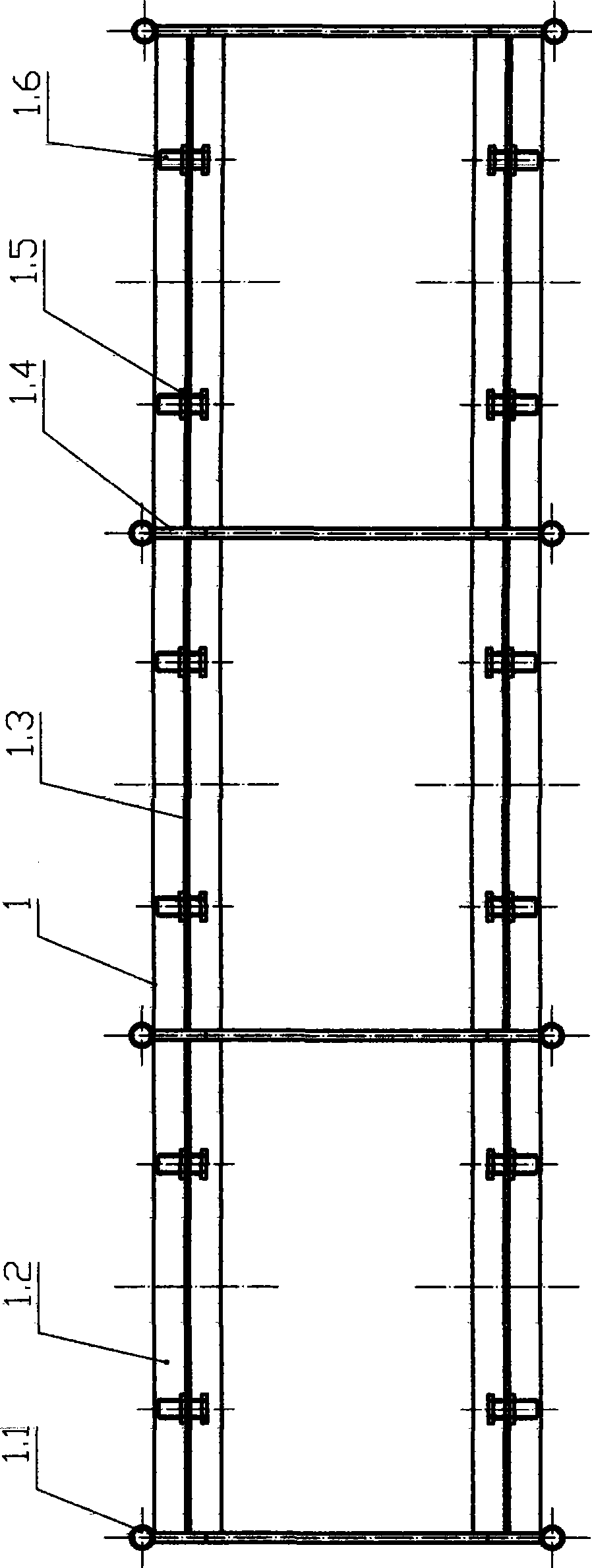

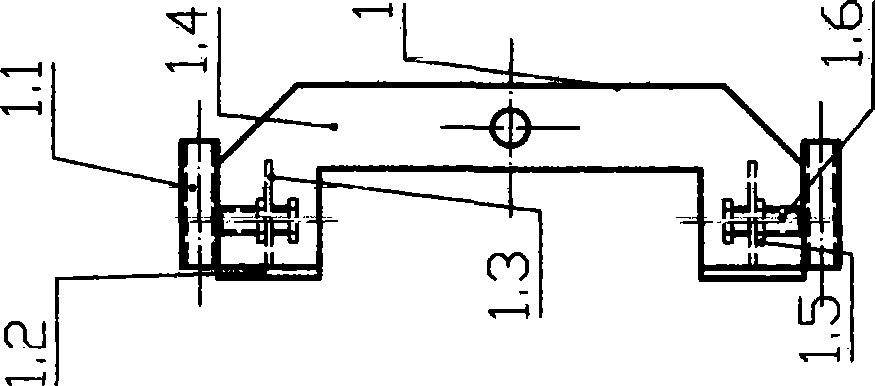

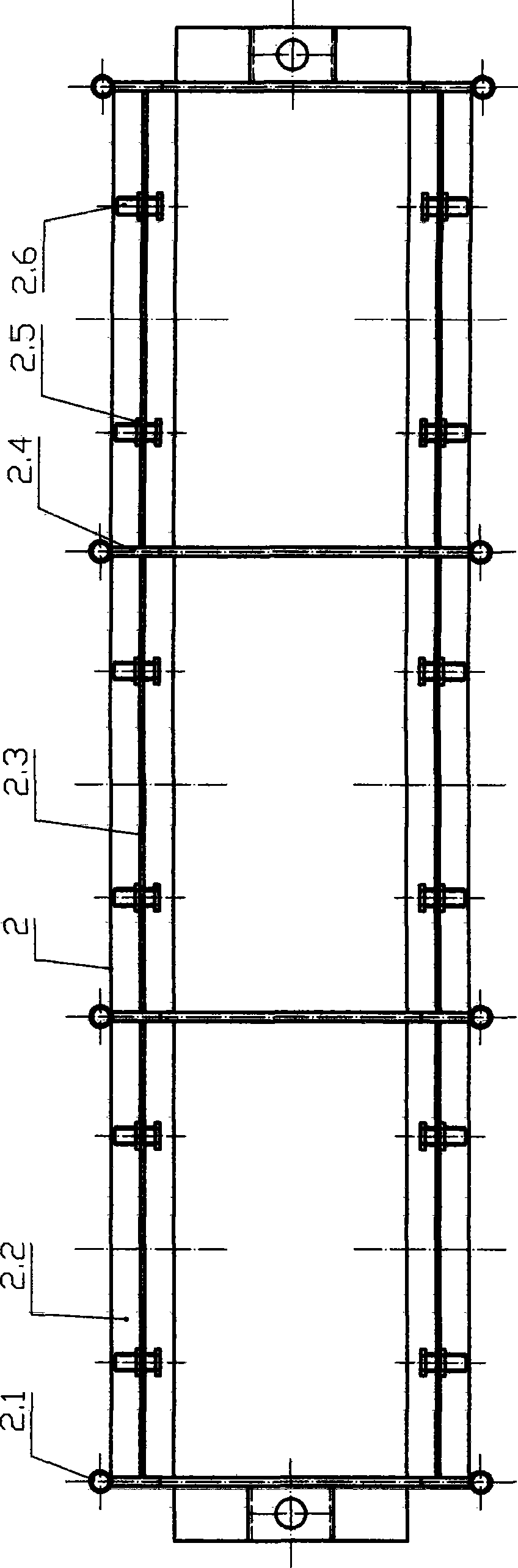

[0012] The two ends of the 4 bow-shaped upper pressure plates (1.4) of the upper clamp (1) are respectively welded to the 4 sets of upper steel pipes (1.1), and the upper top plate (1.2) and the upper fixing plate (1.3) are T-shaped welded and connected to the upper The pressing plate (1.4) is connected as a whole; several sets of upper threaded assemblies composed of upper nuts (1.5) and upper bolts (1.6) are connected with the upper fixing plate (1.3); the four bow-shaped lower pressing plates (2.4) of the lower clamp (2) ) are respectively welded to 4 sets of lower steel pipes (2.1), the lower top plate (2.2) and the lower fixing plate (2.3) are welded in a T-shape and connected to the lower pressure plate (2.4) as a whole, and the lower nut (2.5) Several groups of lower thread assemblies formed with lower bolts (2.6) are connected with the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com