Clothing product line equipment control method and system

A production line equipment and control method technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of slow communication speed, poor stability compared with PLC, inconvenient maintenance, etc., and achieve easy inquiry, efficiency, stability and reliability Improved performance and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

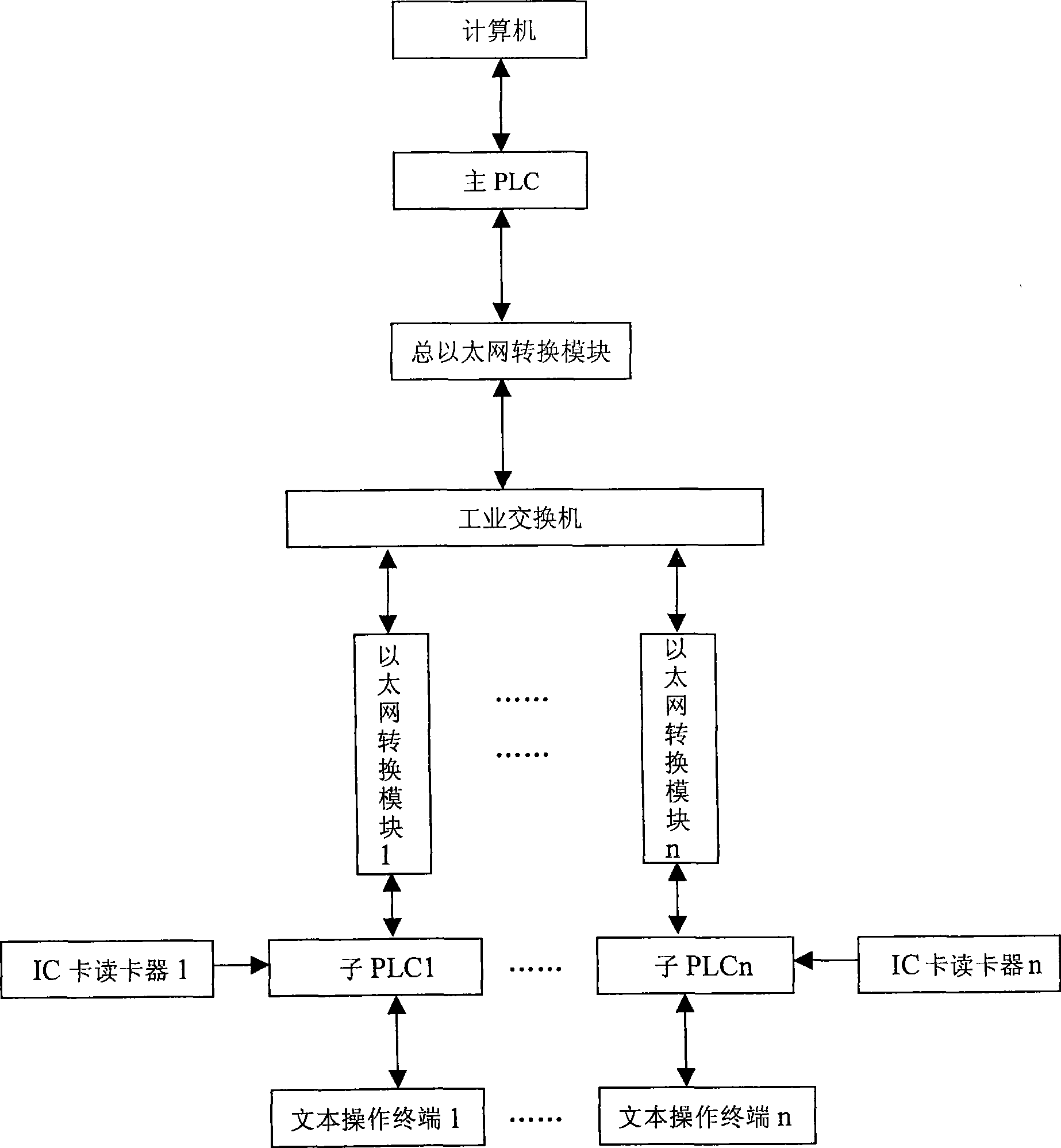

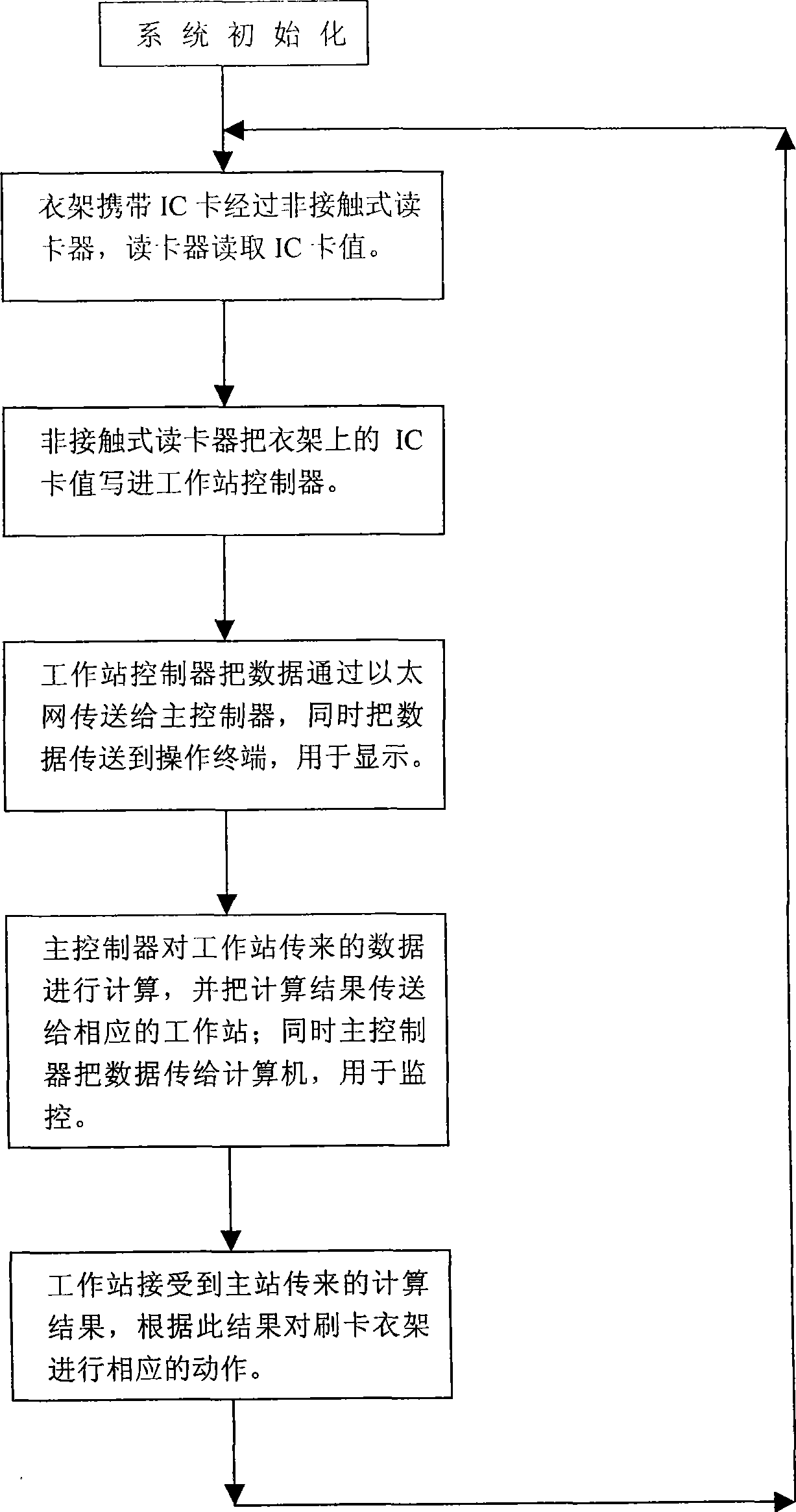

[0025] According to attached figure 1 and 2 , in the clothing production line equipment control system, the computer directly monitors the main PLC, the main PLC is in the Modbus communication protocol slave station mode, correspondingly, the sub-PLC on the assembly line is in the Modbus communication protocol master station mode, and realizes the query to the main PLC. All processing stations on the assembly line are equipped with a set of equipment, and each set of equipment includes a sub-PLC, an Ethernet conversion module, a non-contact card reader, and a text operation terminal for operators to read information and perform related operations. Each PLC is equipped with an Ethernet conversion module. The total Ethernet conversion module connected to the main PLC realizes the connection conversion through the industrial switch and the Ethernet conversion module connected to each sub-PLC in the assembly line. When multiple sub-PLCs send requests to the main PLC at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com