Intelligent numerical control method with three-stage process self-optimization function

A self-optimizing, intelligent control technology, applied in the direction of digital control, adaptive control, electrical program control, etc., can solve the problems of manual error, error, high cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The intelligent control method of the present invention will be described in detail below by taking the intelligent numerical control system integrated with the self-optimizing function of three-level machining constructed according to the intelligent control method of the present invention as an example.

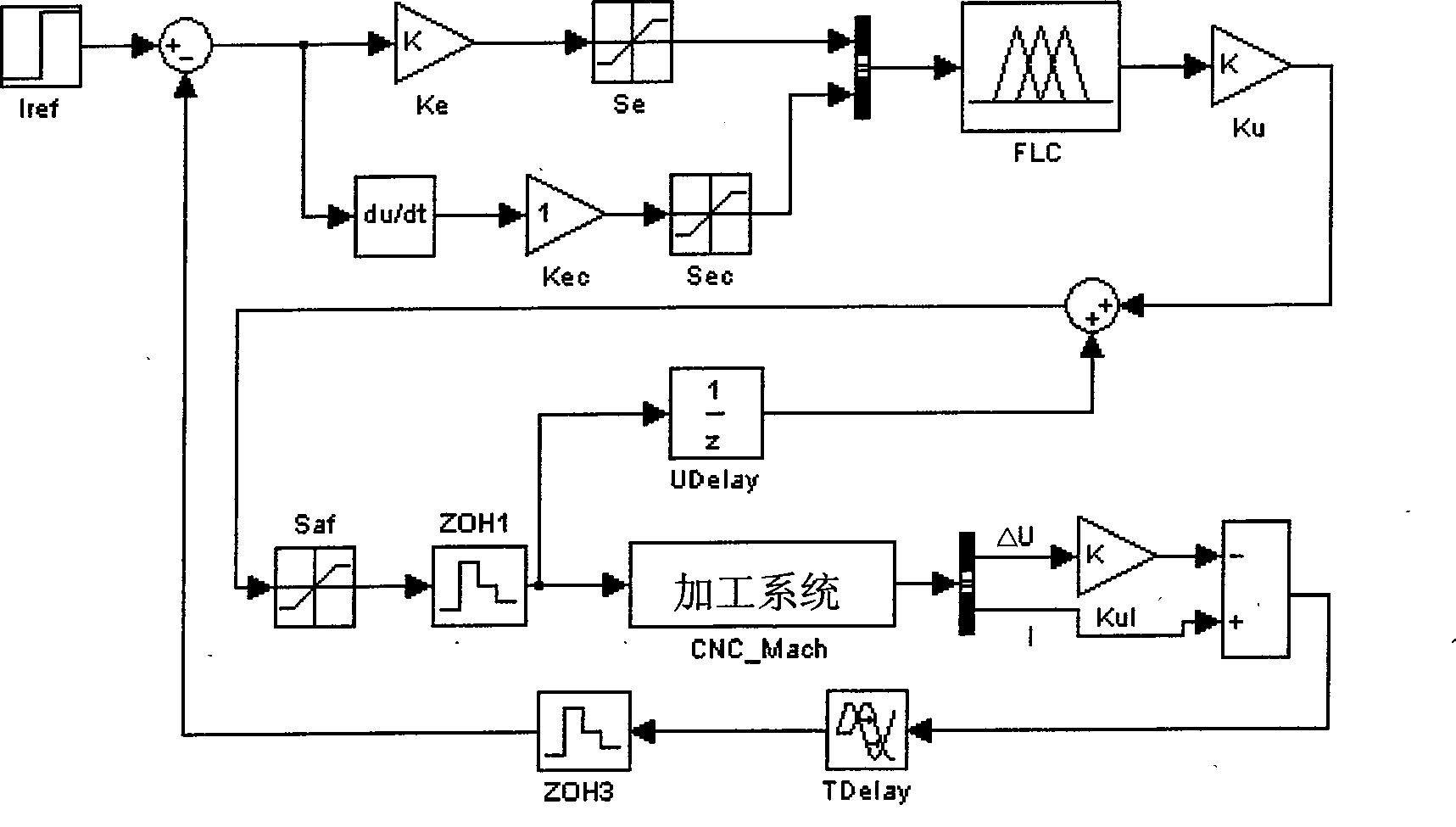

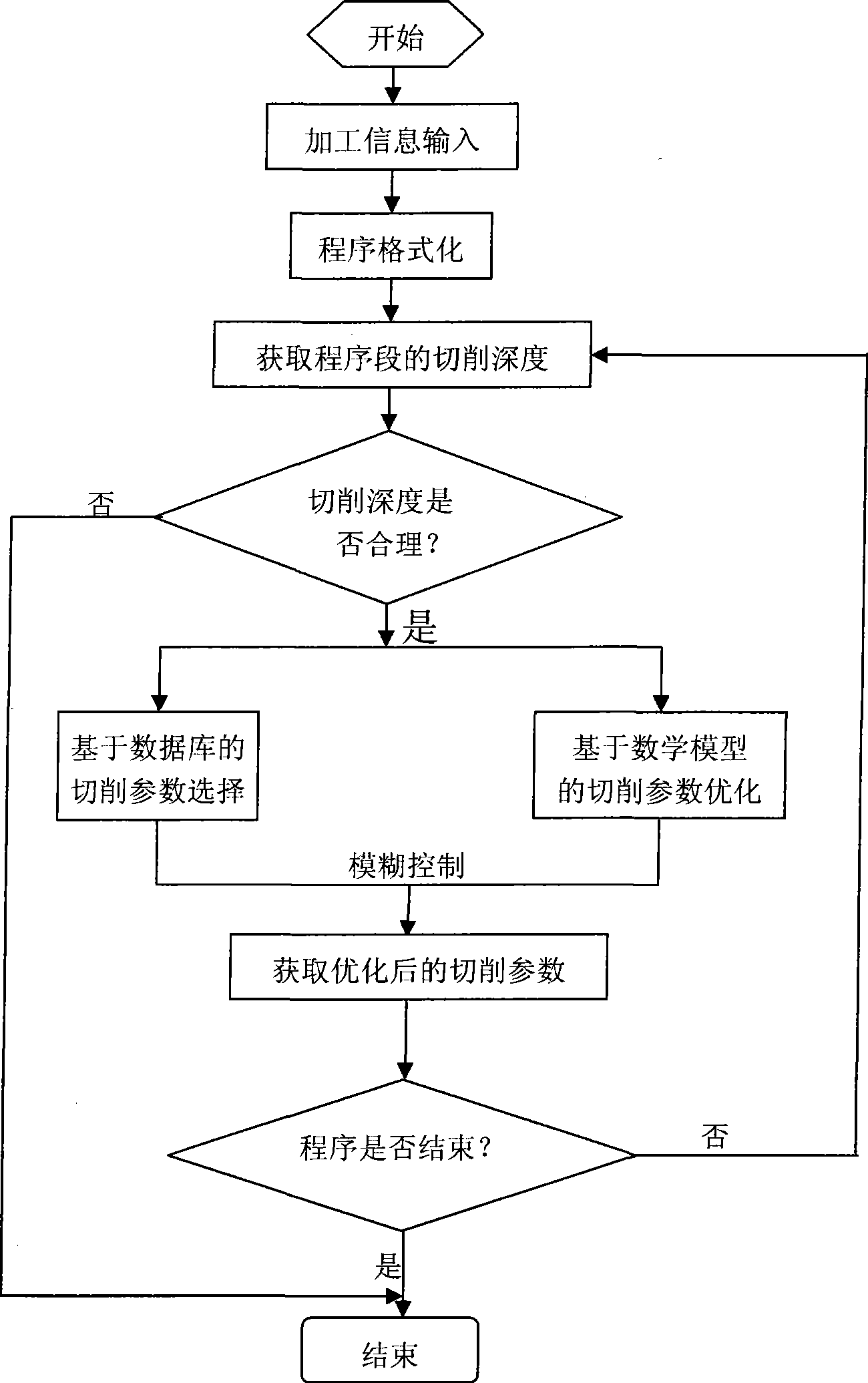

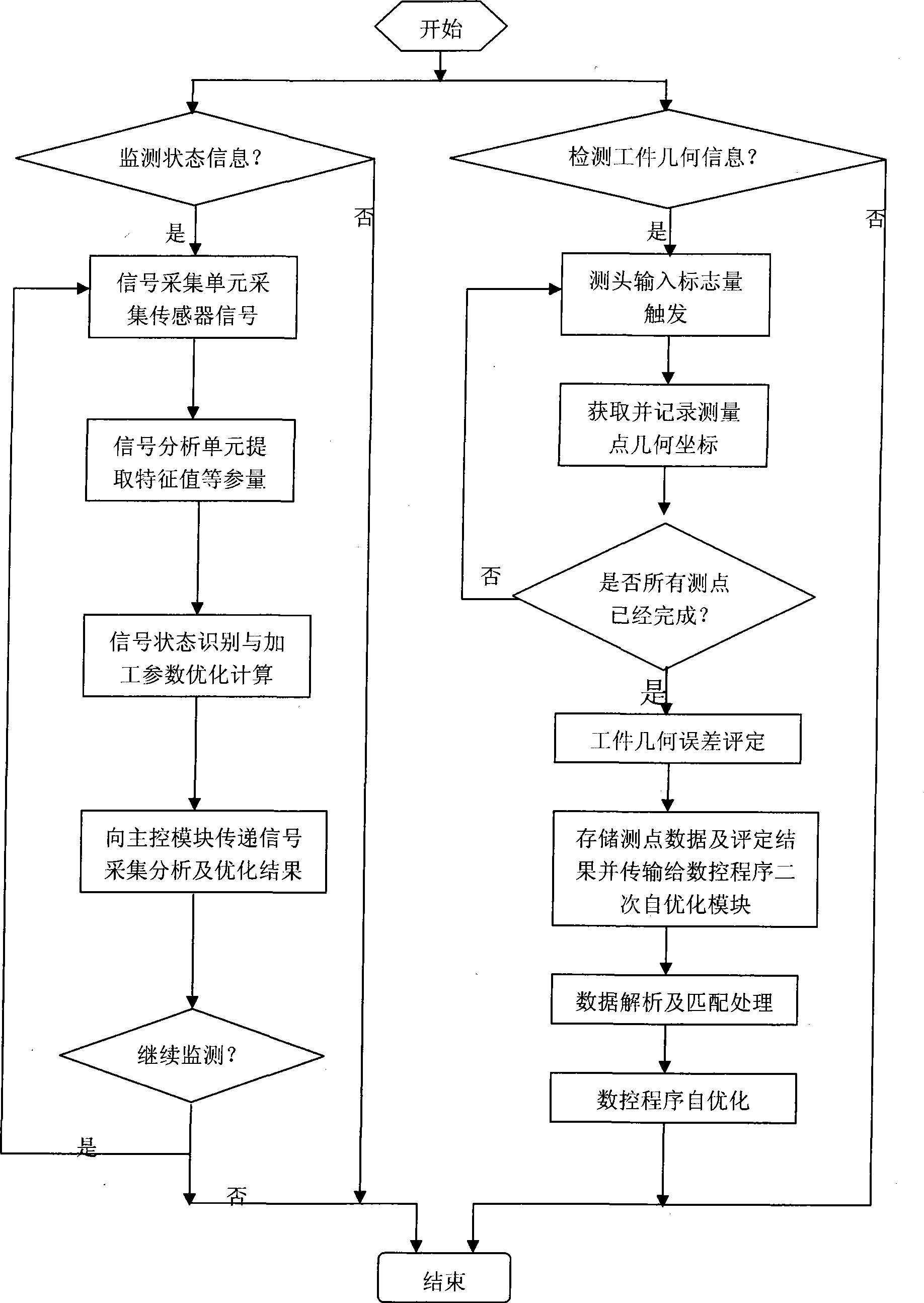

[0026] The numerical control system of the present invention is mainly divided into a main control module, a motion control module, a communication module, a numerical control program processing parameter self-optimization module, a processing operation real-time optimization module, an on-machine detection module and a numerical control program secondary self-optimization module. Except that the motion control module and the acquisition and analysis unit use high-speed DSP as independent core processors, the rest share high-performance microprocessors with the main control module. The modules are linked through the system internal bus 1 to realize function calling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com